At the current stage of industrial development, oil and gas are the most popular commodities. Oil and petroleum products have penetrated almost every sphere of human activity, from fuels for transport, to cosmetics and medicines.

Natural gas is the most popular fuel in power generation stations, the cement and glass industry, the building material industry, domestic use, non-ferrous and ferrous metallurgy, metal smelting, glass production, as well as raw material for organic compounds in synthesis and other applications.

Most oil and gas is found at great depths of 6 kilometers or more. Wells are required to get these resources, and different types of drilling rigs are used to drill the wells.

Triol Corporation offers a special range of equipment for powering and controlling the motors of various types of drilling rigs – AT24 DW line (Drill Wise).

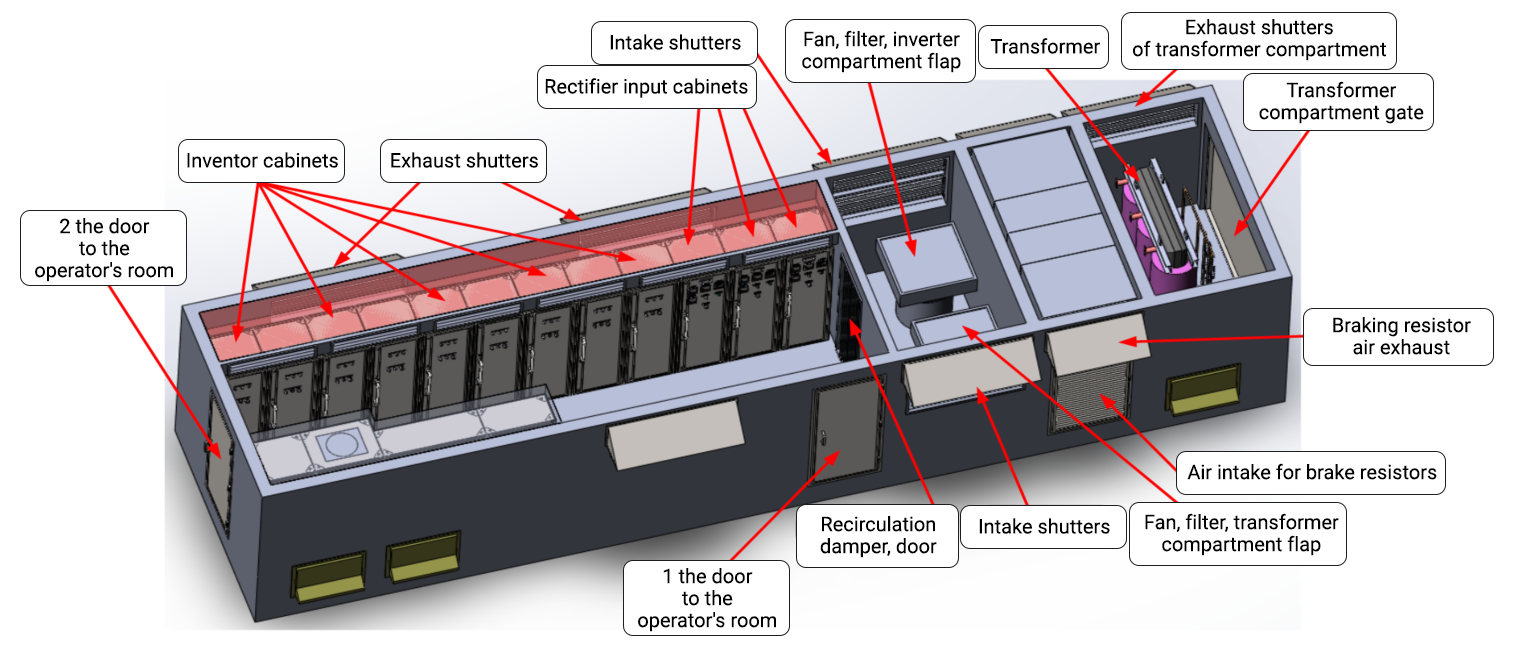

The DW line includes the following devices:

CTU TDCS –- Complete transistor unit for controlling the top drive control system

CTU MP - Complete transistor unit for controlling mud pumps

CTU TWU - Complete transistor unit for controlling tower-winch unit

CTU - Complete transistor unit for controlling the complete equipment: mud pumps, tower-winch unit, and rotor

LVSC - Low-voltage switchgear and control unit for powering and controlling the auxiliary machinery of a drilling rig

Our design challenges:

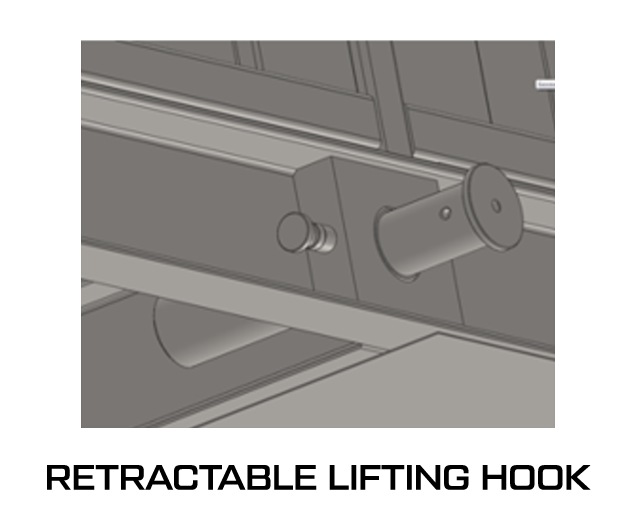

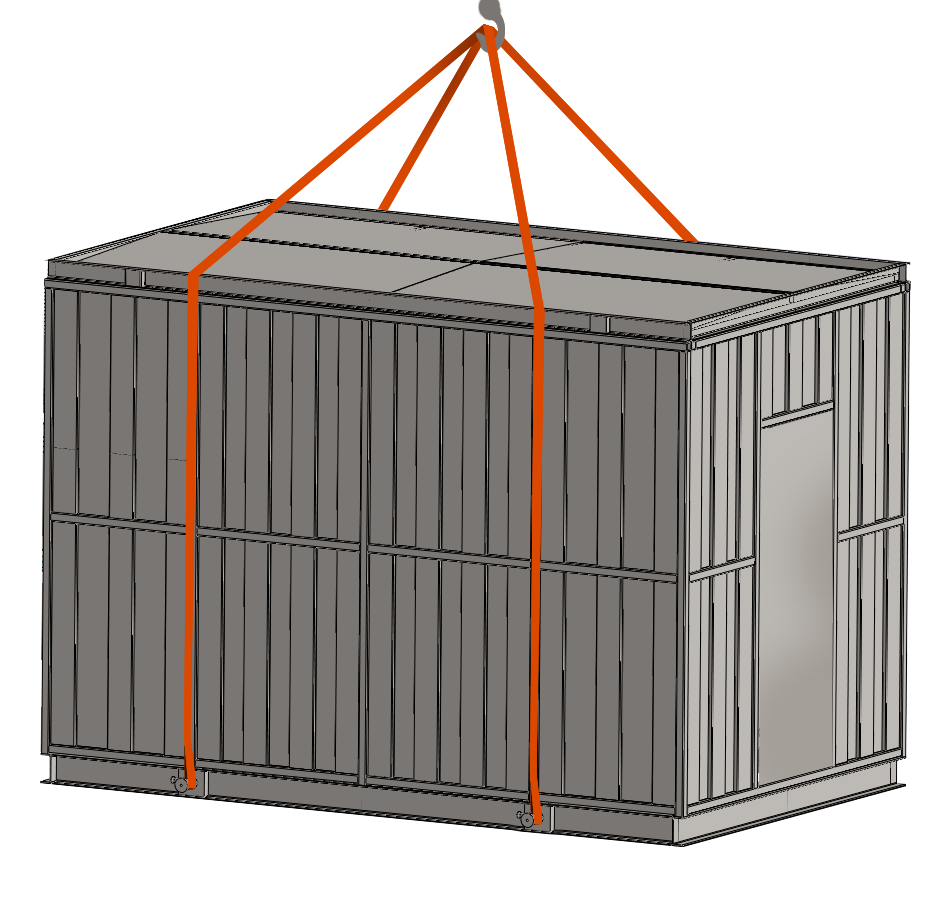

1) High equipment mounting capability;

2) The maintainability;

3) The conditions inside the container;

4) Staff comfort;

5) The location of the VFD in the boxes;

6) An individual approach;

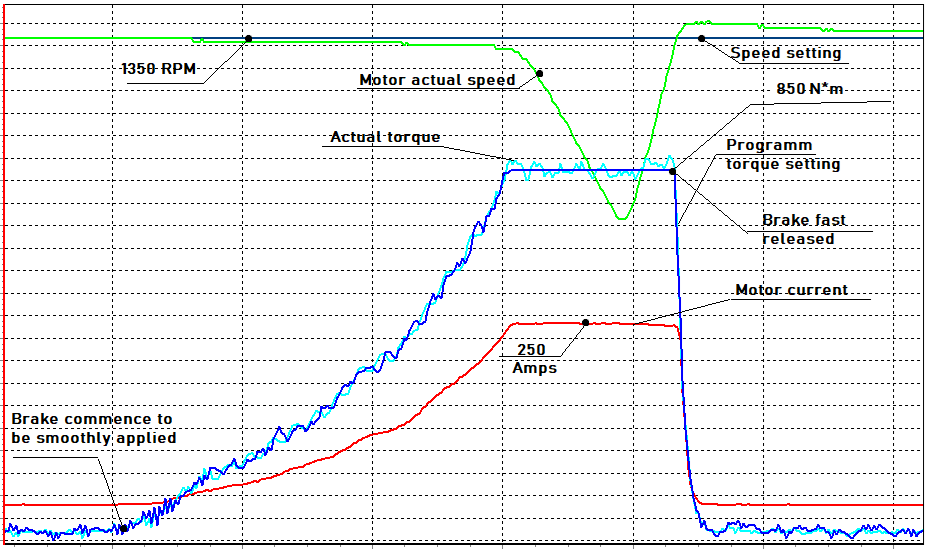

7) Vector control;

8) Dual-motor operation with master-slave algorithm.

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google