One of the most popular sectors for the application of variable frequency drives is housing and communal services, in terms of water supply and wastewater disposal systems, as well as heating, ventilation, and air conditioning.

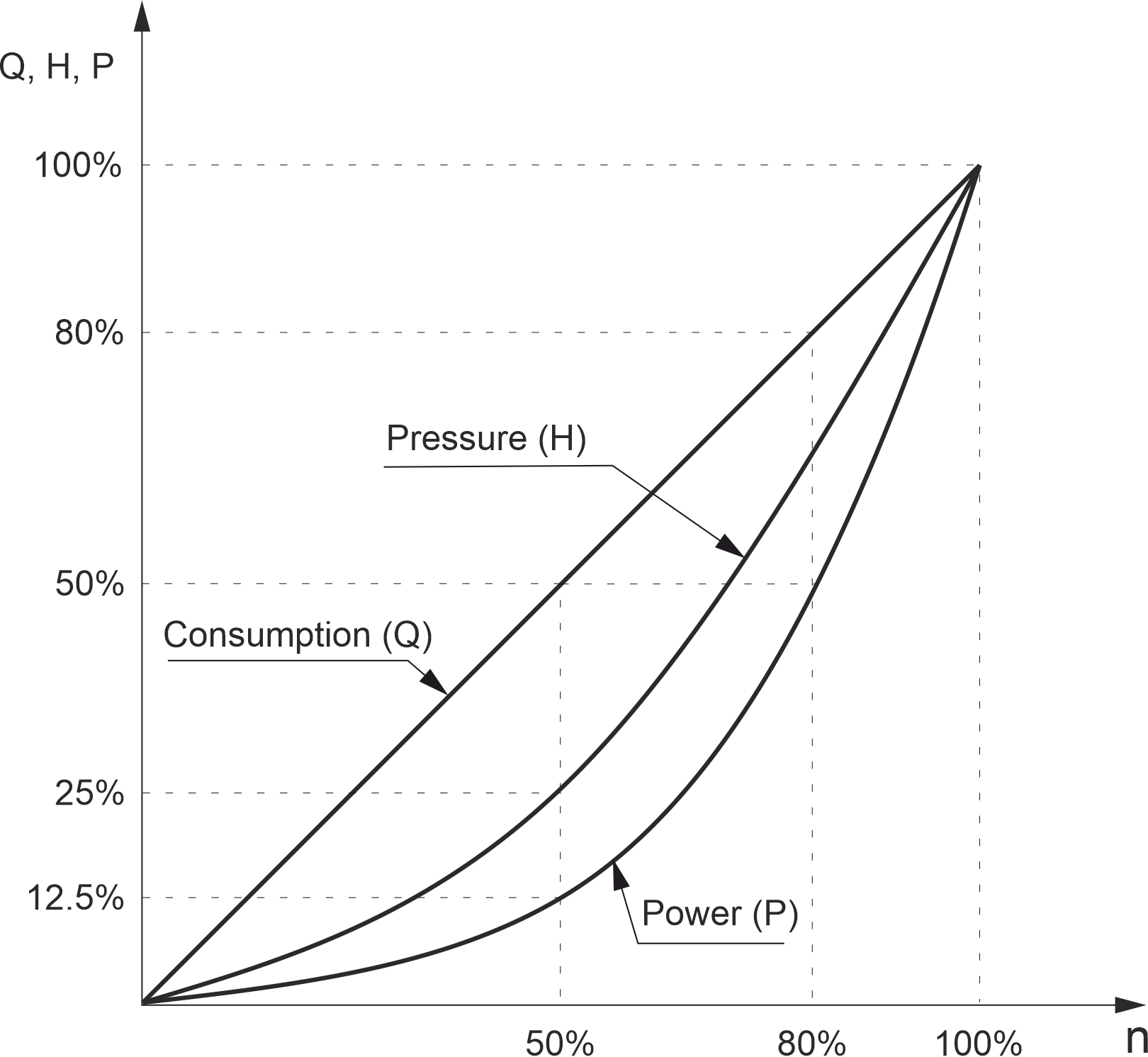

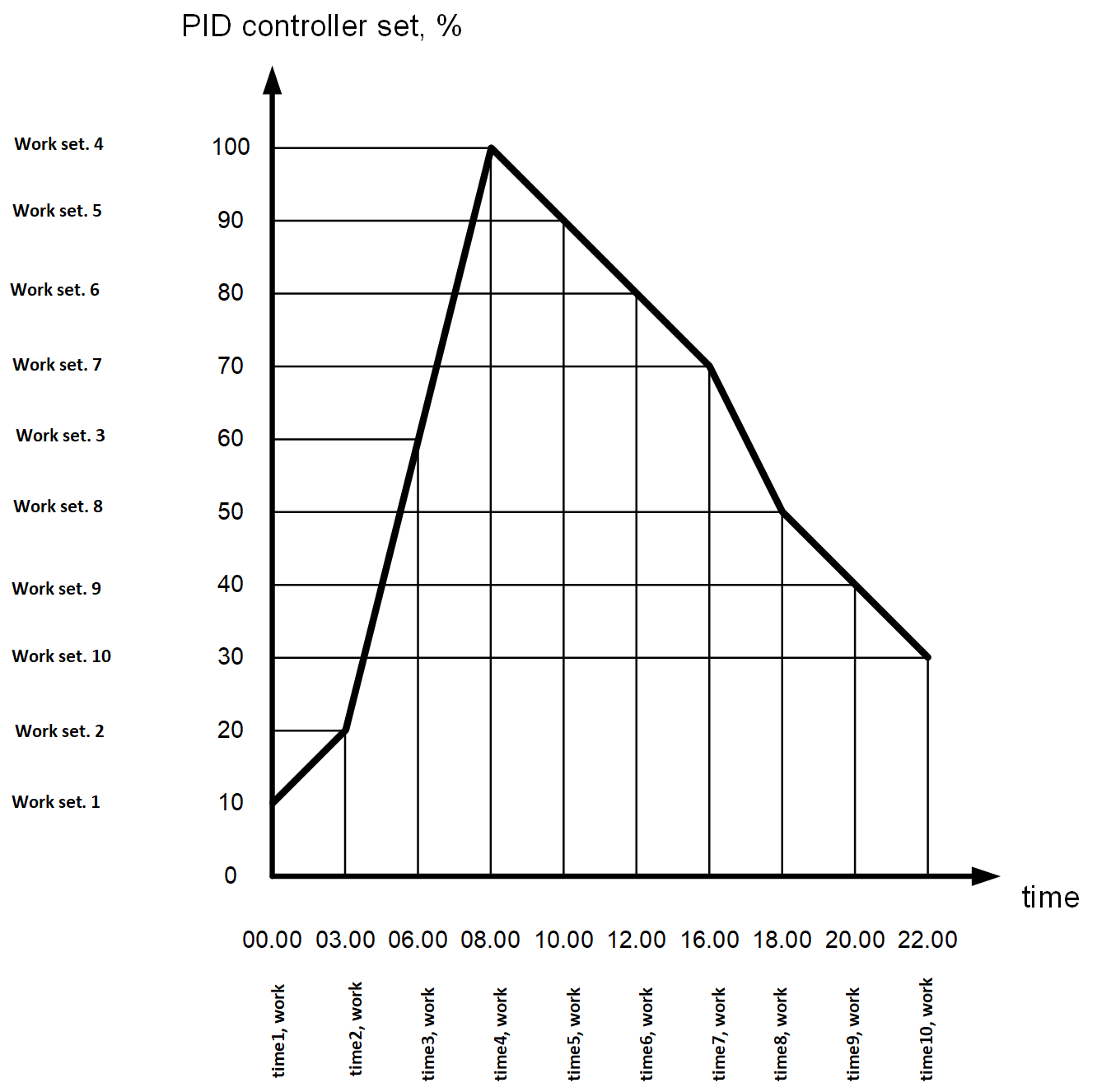

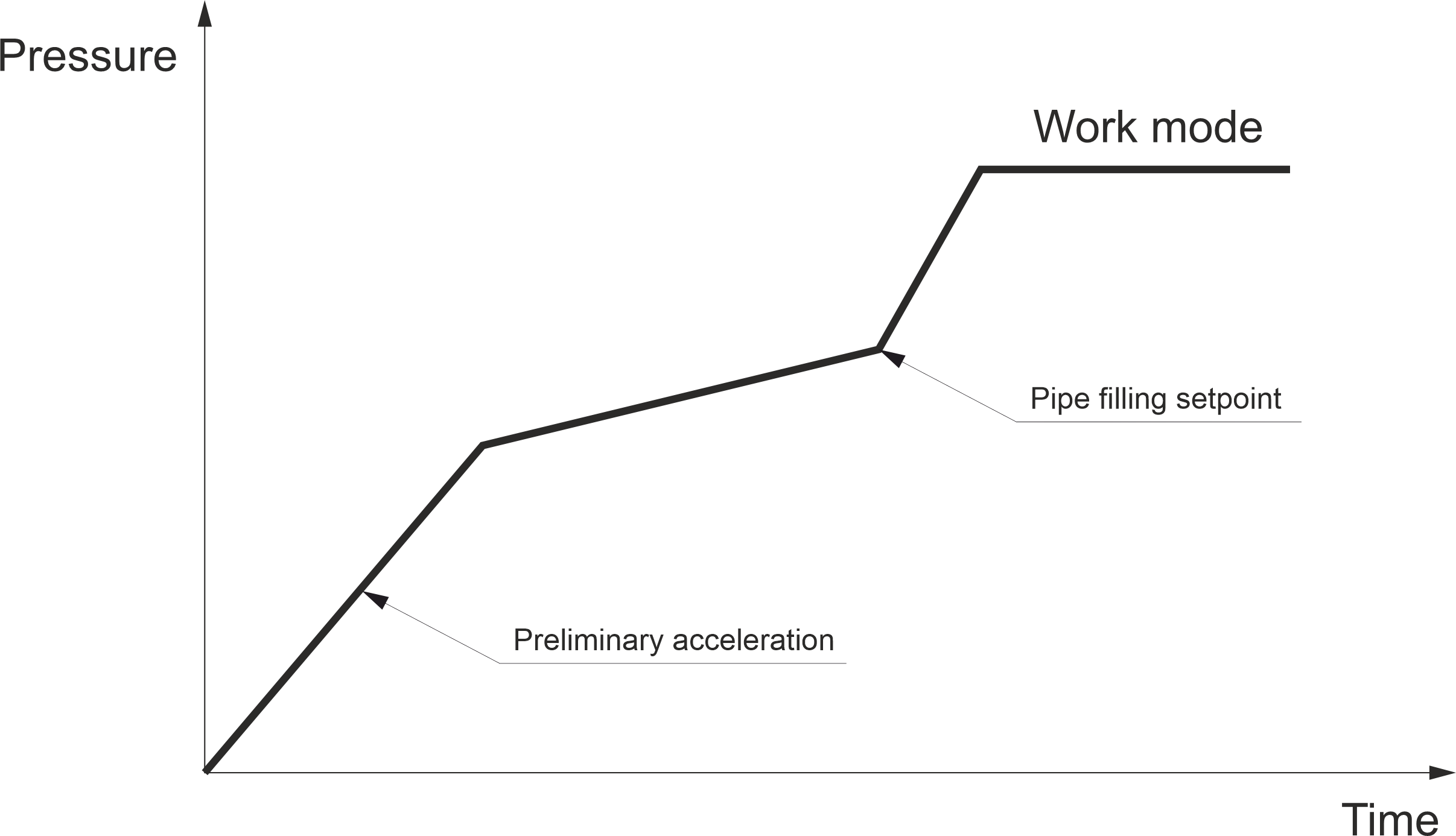

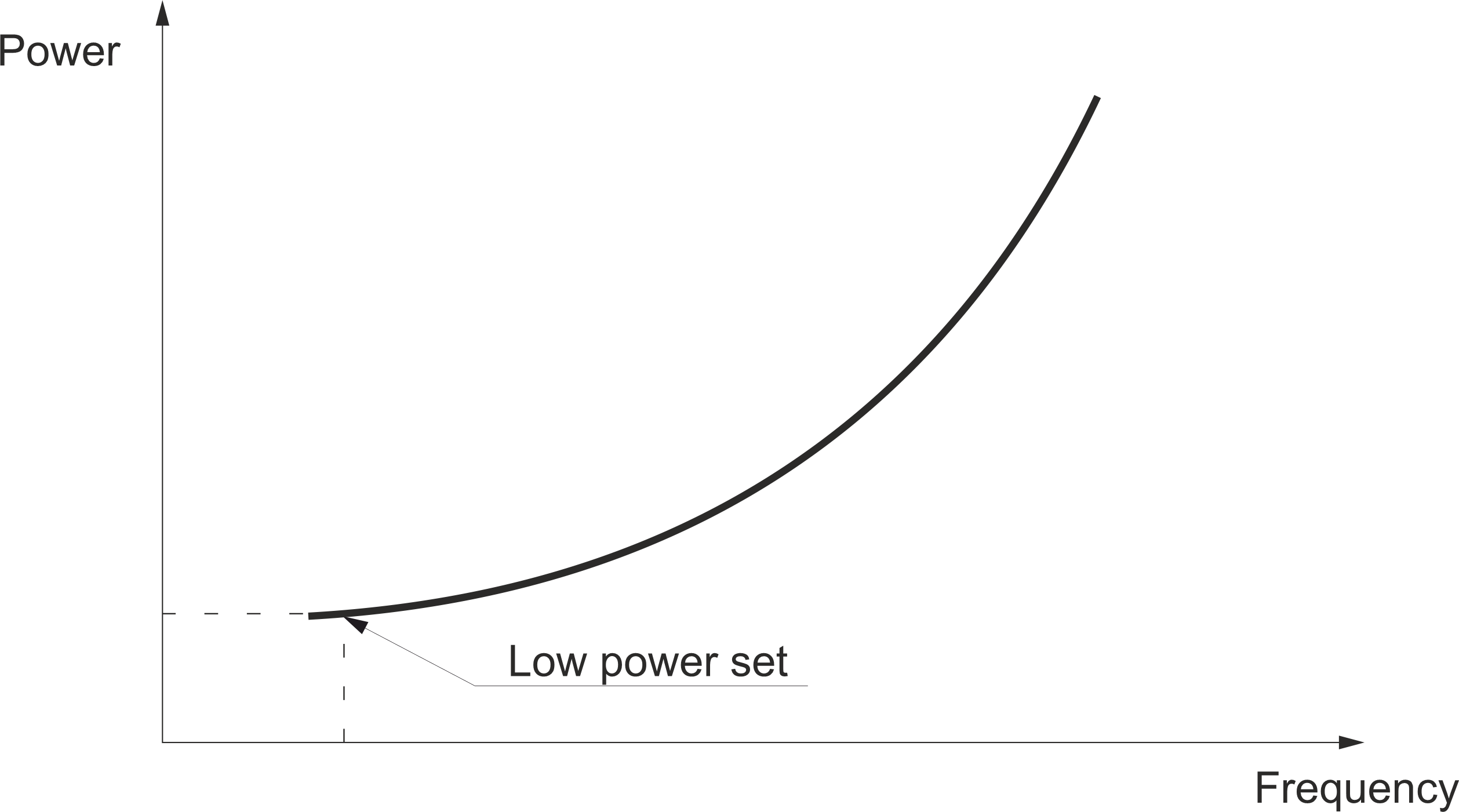

The main requirements of variable frequency drives in this segment are high energy efficiency, the ability to extend the life of equipment, and reliability.

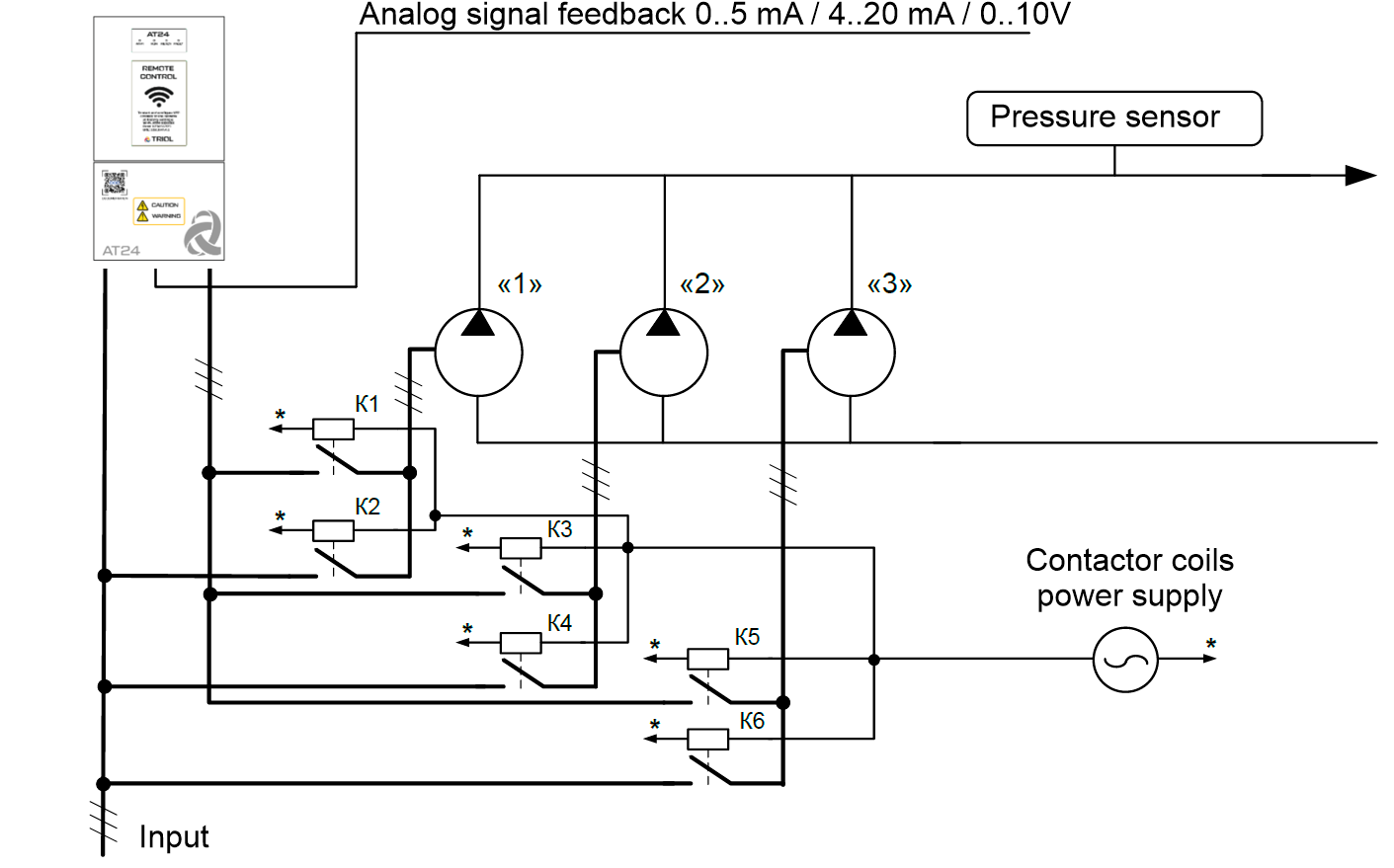

Triol Corporation offers reliable and efficient solutions for motor control in pump and HVAC systems – the AT24 VFD series UC, UH, and SD lines.

The adaptability of the series of variable frequency drives meets the needs of any object, and a wide range of expansion units and communication protocols allows for integration into any industrial control system (ICS).

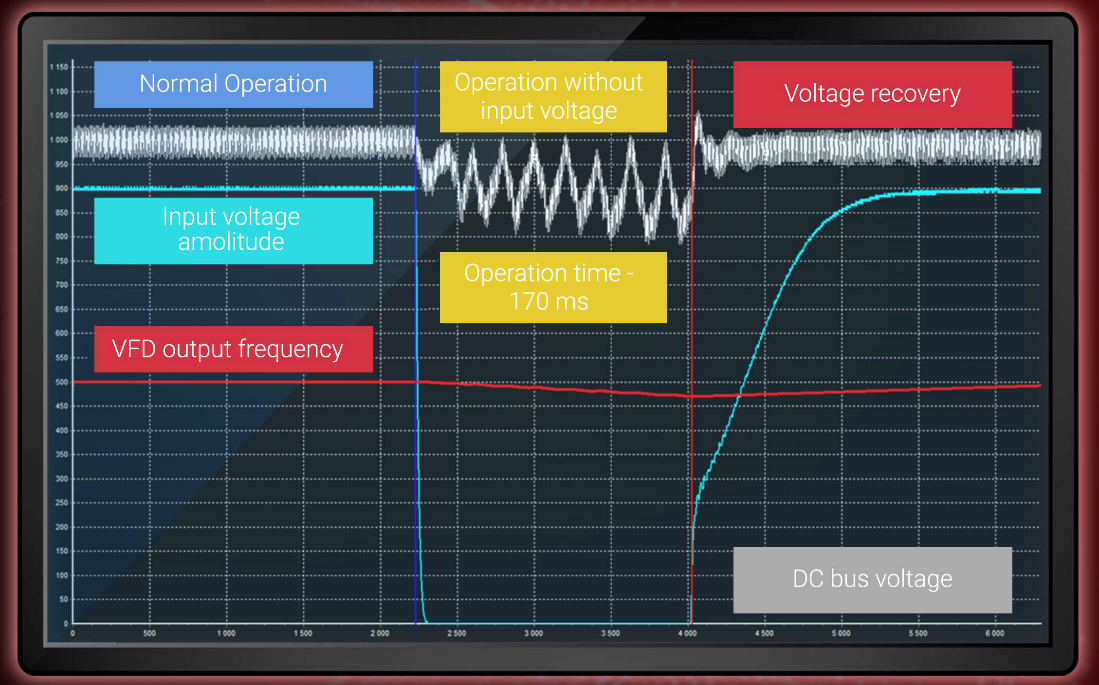

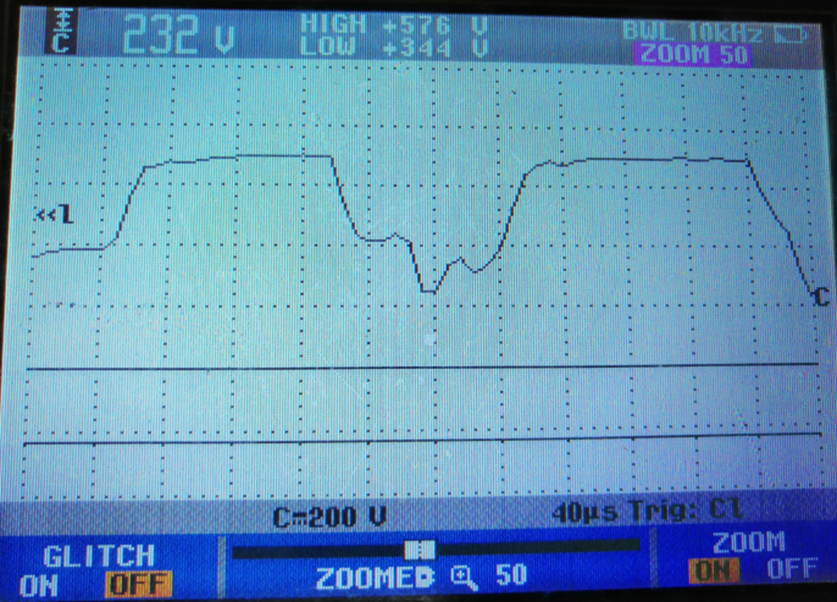

The optional filling of the AT24 series allows the equipment to operate under any conditions: weak networks, old motors, long line from the VFD to the motor, IEEE 519 compliance requirements.

The AT24 variable frequency drive UC line is a reliable and intelligent solution for operation in the conditions of prepared electrical rooms or electrical cabinets.

Nominal voltage: 380–480 V (-15% – +15%).

Output power: 0.37 kW – 400 kW.

Enclosure protection degree: IP20 (0.37–75 kW), IP21 (90–400 kW).

The AT24 variable frequency drive UH line is a reliable and versatile solution for operation in hard environments.

Nominal voltage: 380–480 V (-15% – +15%).

Output power: 5.5 kW – 400 kW.

Enclosure protection degree: IP55.

The AT24 variable frequency drive UH line is a compact and powerful solution, created in a modular design, which is used to control powerful pumps, fans, compressors, and other electrical drives in specialist and general industrial applications.

Nominal voltage: 380/480/690 V (-15% – +15%).

Output power: 110 kW – 3200 kW.

Enclosure protection degree: IP54.

Our challenges.

1. Energy efficiency.

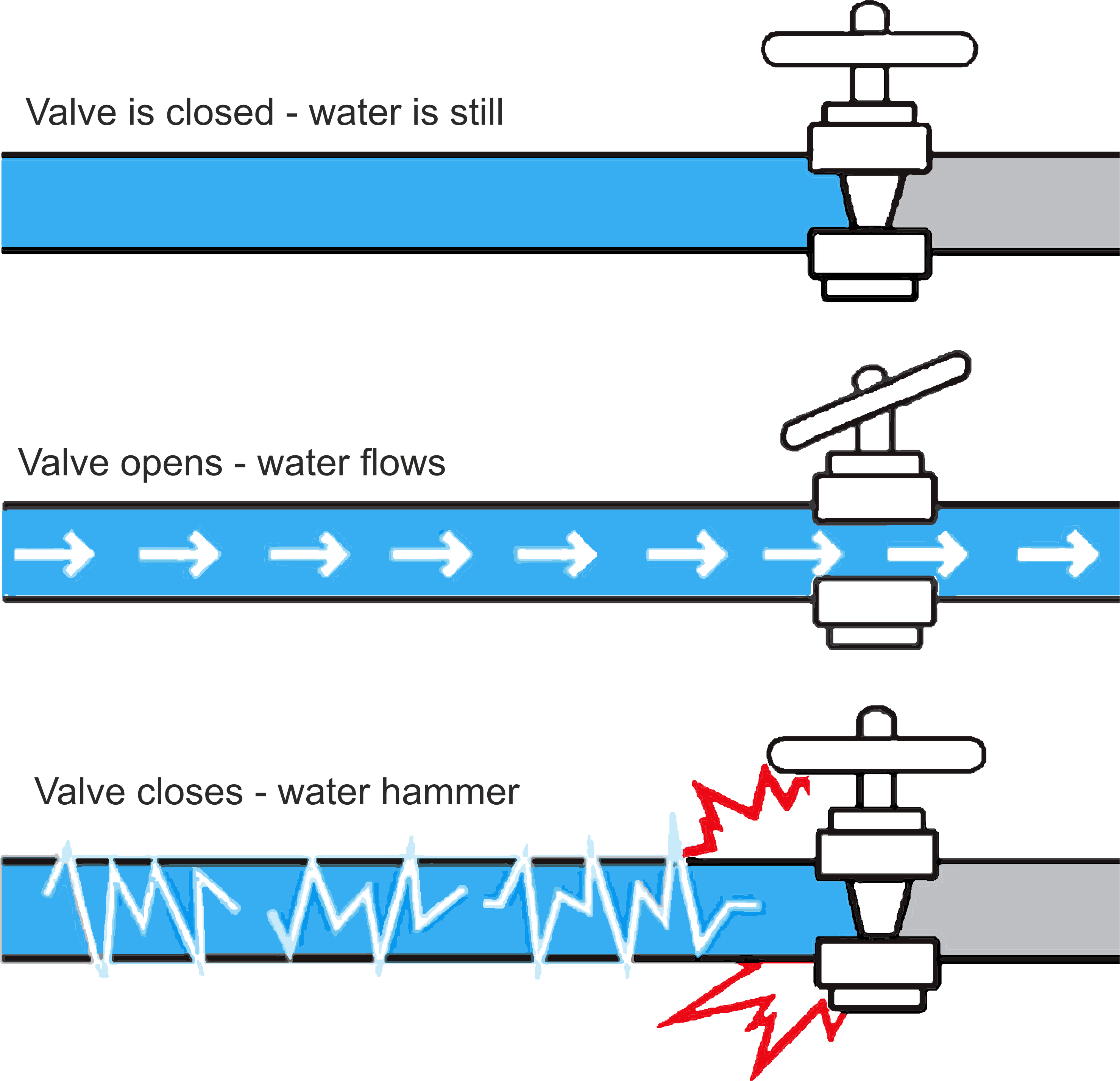

2. Extension of the equipment lifetime.

3. Reliability.

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google