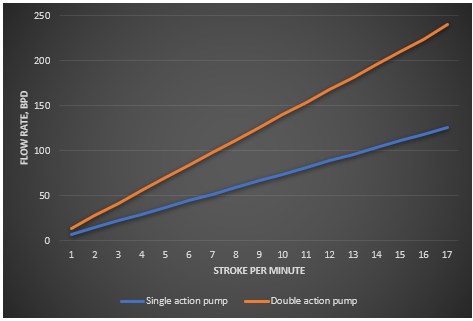

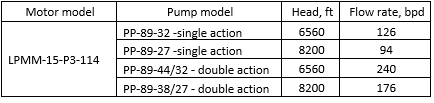

As we gained experience with the EP01 and received customer feedback, Triol determined that the target flow rate for the EP01 is wells with flow rates up to 300 bpd and pressures up to 6,560 ft and 8,200 ft. The EP01 single-action unit does not provide this kind of flow rate. The solution is obvious at first sight – to increase the unit’s power and thereby expand the range of products. But Triol specialists have set themselves the task that the modernization of EP01 provides a number of advantages such as:

- doubling the flow rate as compared to single-pass units;

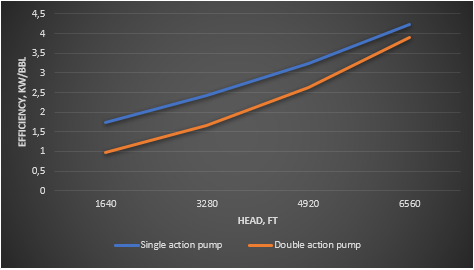

- reduced energy consumption per barrel of oil produced;

- unification of motors with the expansion of the feed range;

- ensuring a service life of at least 9 million cycles;

- improved maintainability; and

- customization for different operating conditions.

Therefore, after a conceptual study of this issue, we came up with a non-standard and novel solution to the double-action pump scheme, which allows us to increase the flow rate by half while maintaining the power of the motor.

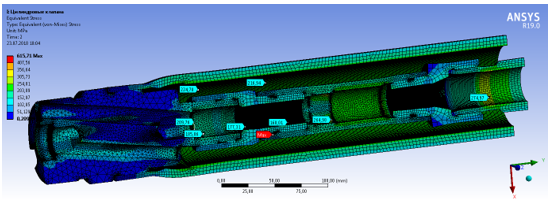

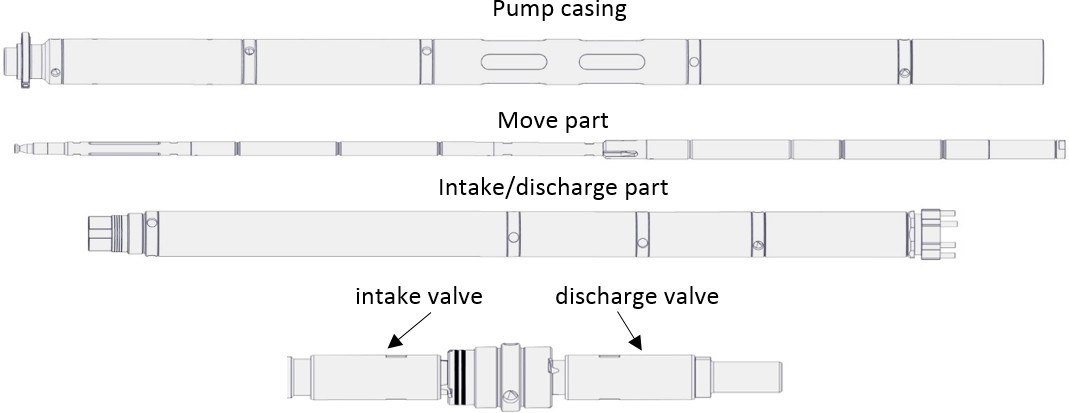

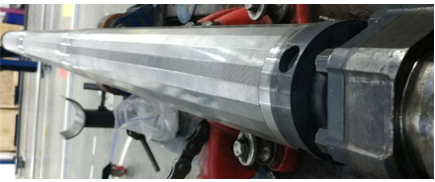

Figure 1 - Submersible part of the EP01 double-acting unit

The main advantages of this offer will be discussed below.

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google