A ship on the open sea is an isolated ecosystem. Because of its significant distance from any auxiliary objects and external sources, the successful functioning of a ship depends on the ship’s technical equipment and the qualifications of its crew. Therefore, marine engineering is one of those industries in which all equipment must meet a high standard, especially its electrical engineering unit.

For electrical equipment, these requirements can include minimum power consumption for each mechanism; maximum service life; maximum usable footprint; and minimum maintenance costs. Let's review how frequency control of the ship's electric motors allows it to meet these requirements.

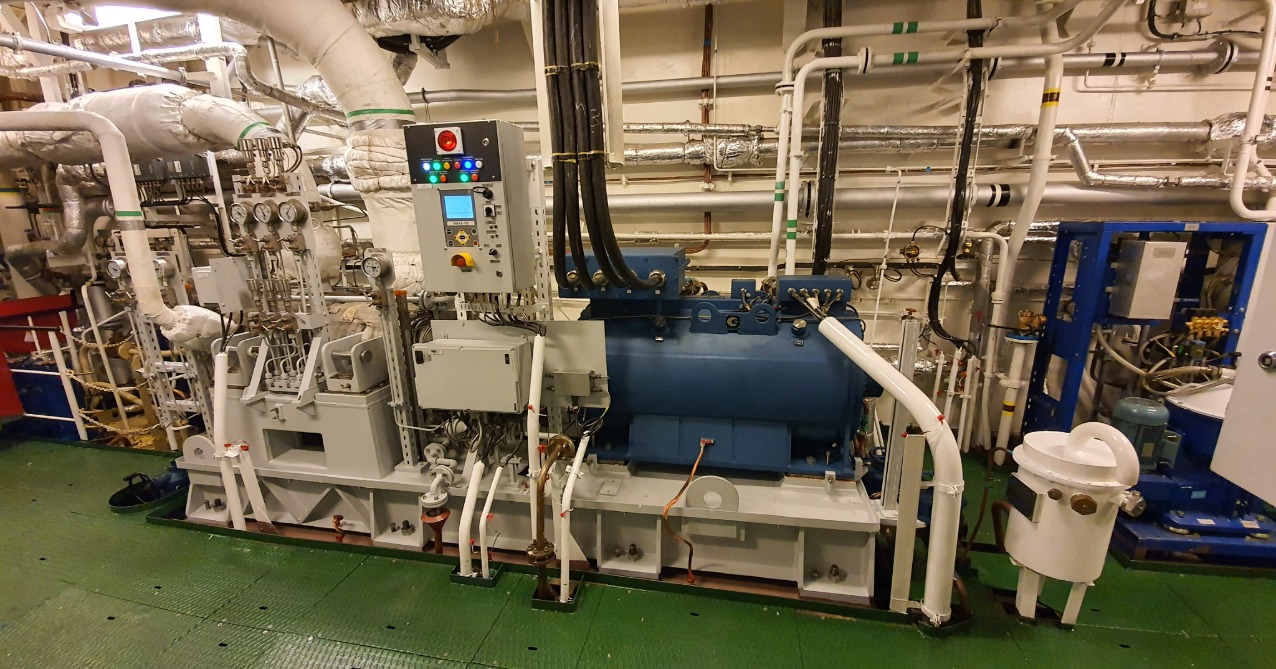

The application of variable frequency drives in the marine industry helps ships achieve effective control of the electric motors of thrusters and steering mechanisms, propulsion units, pumping and compressor equipment, ventilation systems, cranes and winches. The electric motors ensure the smooth and well-coordinated work of the whole vessel, assist in more productive use of internal equipment resources, and at the same time ensure safety and security of the vessel's electrical equipment. In addition, variable frequency drives increase the overall reliability of regulated mechanisms and improve the environmental compatibility of marine transport.

Proper selection and use of frequency drive solves the above problems in the following ways:

-

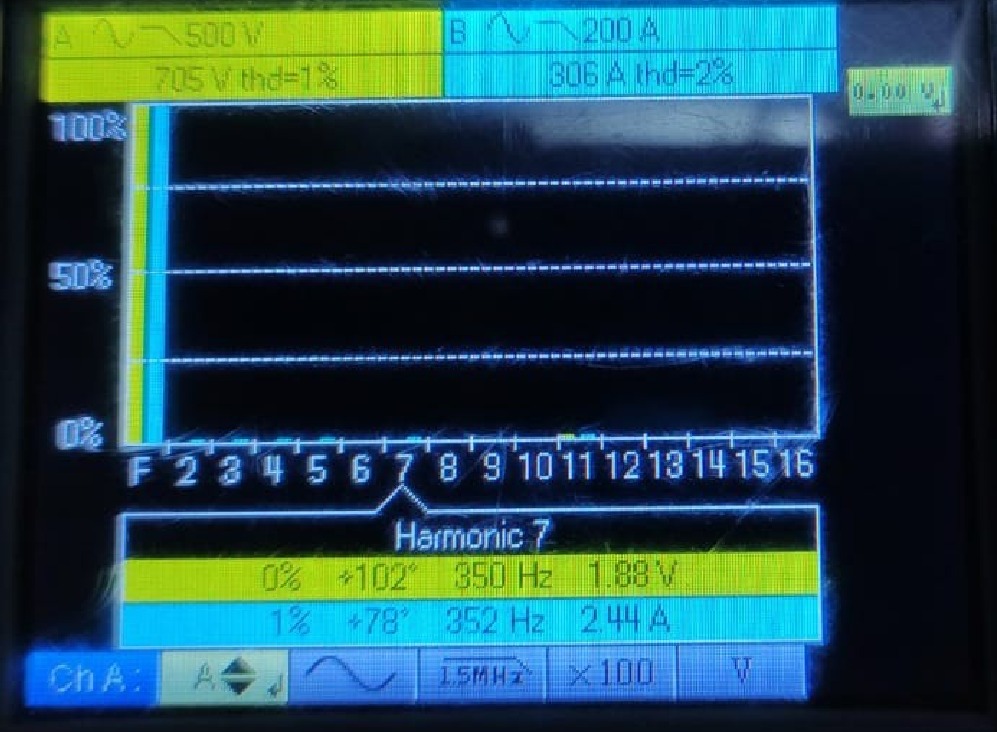

Reduces inrush currents, and consequently sags in the network, thereby increasing the quality of voltage in the network of the ship;

-

Increases equipment life by reducing loading during launch and acceleration;

-

Contributes to the increase of useful space due to the fact that it is not necessary to use over-sized equipment;

-

Reduces unnecessary power consumption on the ship.

Triol Corporation offers a premium range of technical solutions based on the low-voltage Triol AT24 drives and the medium voltage Triol AT27 drives, which are compatible with a wide range of marine drive systems. From our point of view, the following 8 advantages make the Triol AT24 and Triol AT27 one of the best frequency drive offerings for the shipbuilding industry.

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google