Triol AT27 variable frequency drives in the metallurgy industry

The wide variety of technological processes in the production of metallurgical products imposes different requirements on the equipment involved. In the production of metal products, the most important processes are ore preparation, coke production, ore smelting, metal casting, and rolling.

The use of a medium-voltage variable frequency drive is possible in each of the above stages, but in our opinion, the highest requirements are placed on the variable frequency drives involved in the final stage of production – rolling. It is the control of the roll drive in a rolling mill that largely determines the quality of the final product and its assortment.

Despite their common purpose, rolling mills differ in design, rolling method, and operating features.

Rolling mills

Depending on the product they produce, rolling mills can be divided into:

- cogging mills (blooming mills, slabbing mills);

- billet mills;

- rail and beam mills;

- sections (heavy, medium, and small sections);

- wire rod mills (for wire rod production);

- plate rolling (for thick, medium, and thin sheets);

- tube-rolling;

- wheel and tire rolling mills;

- mills for special types of rolled products.

The main mechanisms of rolling mills are the rolls of the working stands.

The roll drives can be divided according to the direction of rotation into:

- non-reversible;

- reversible.

and the number of motors:

- single-motor;

- twin-engine.

Our challenges

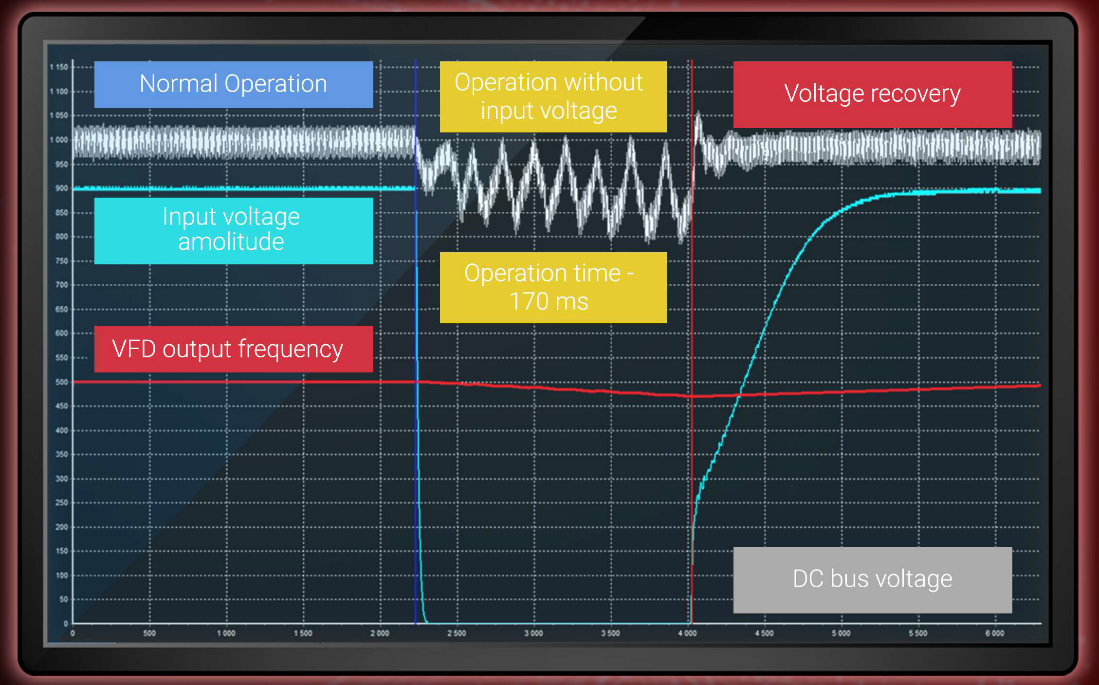

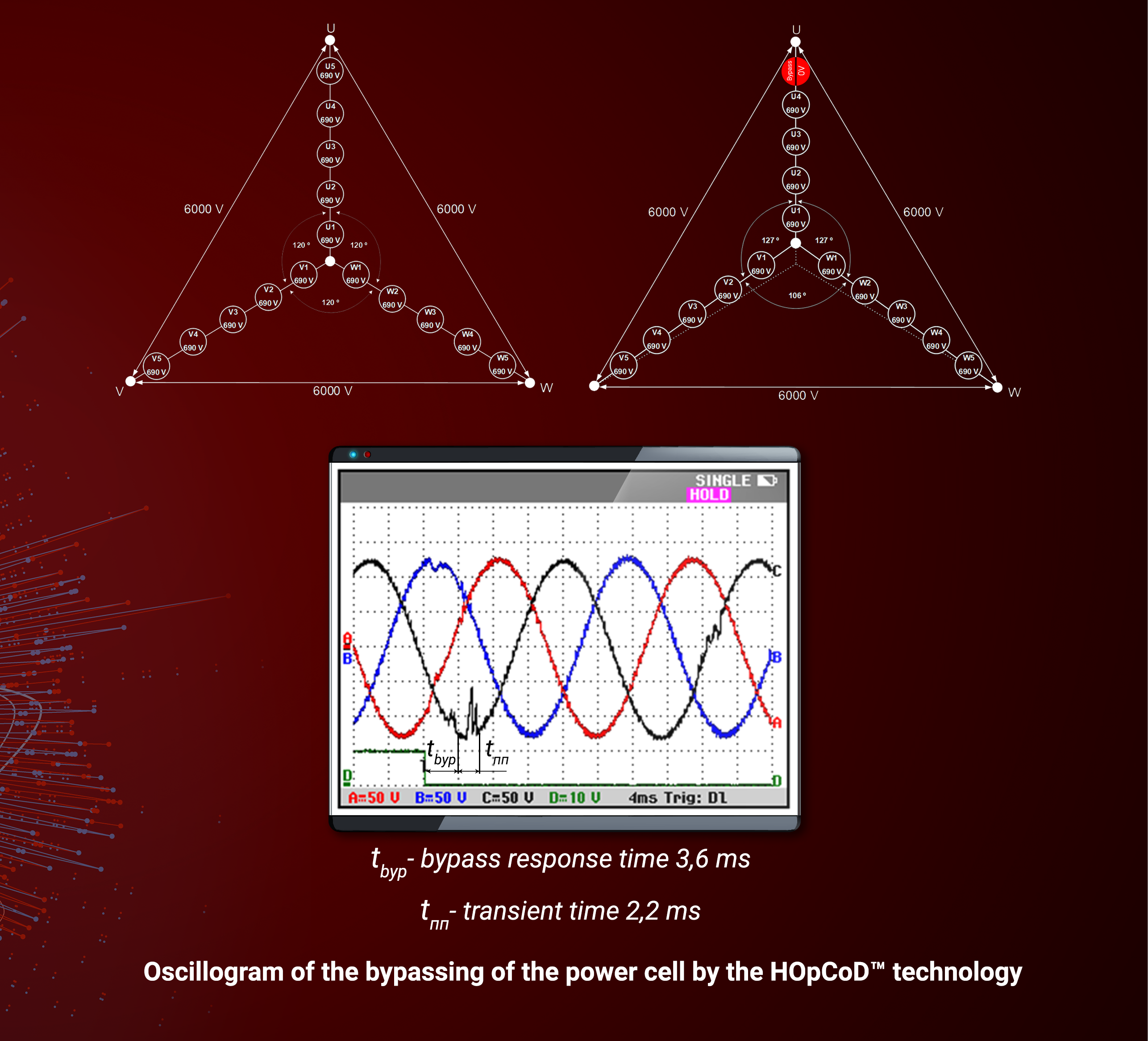

1. A non-stop process.

2. Integration with the process control system.

3. Service life extension.

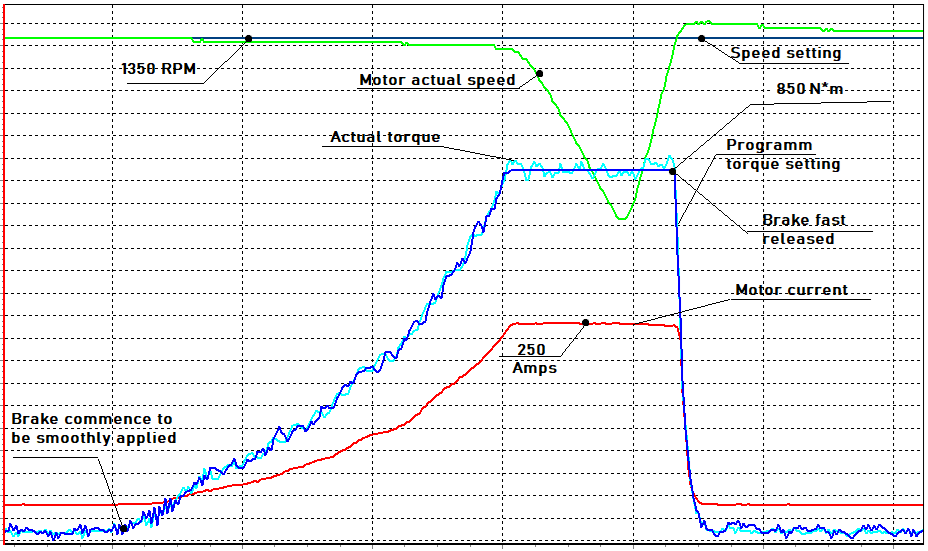

4. Rolling direction reversal and spindle positioning.

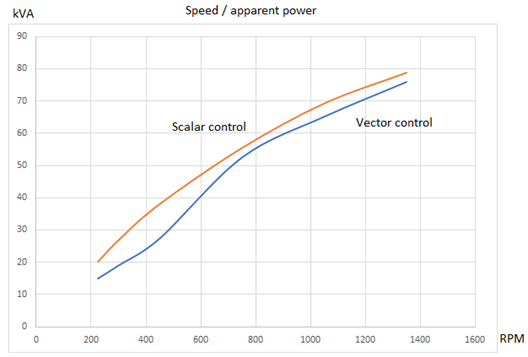

5. Optimization of energy consumption and electromagnetic compatibility.

6. Operation in high dust and conductive dust environments.

7. Efficient operation in twin-motor mode.

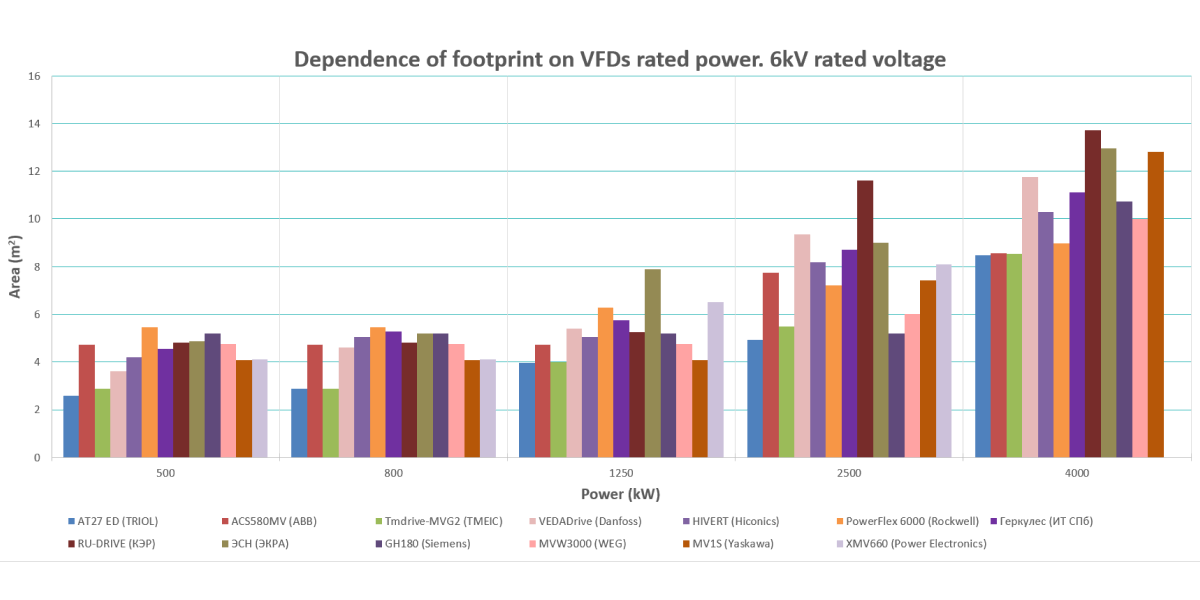

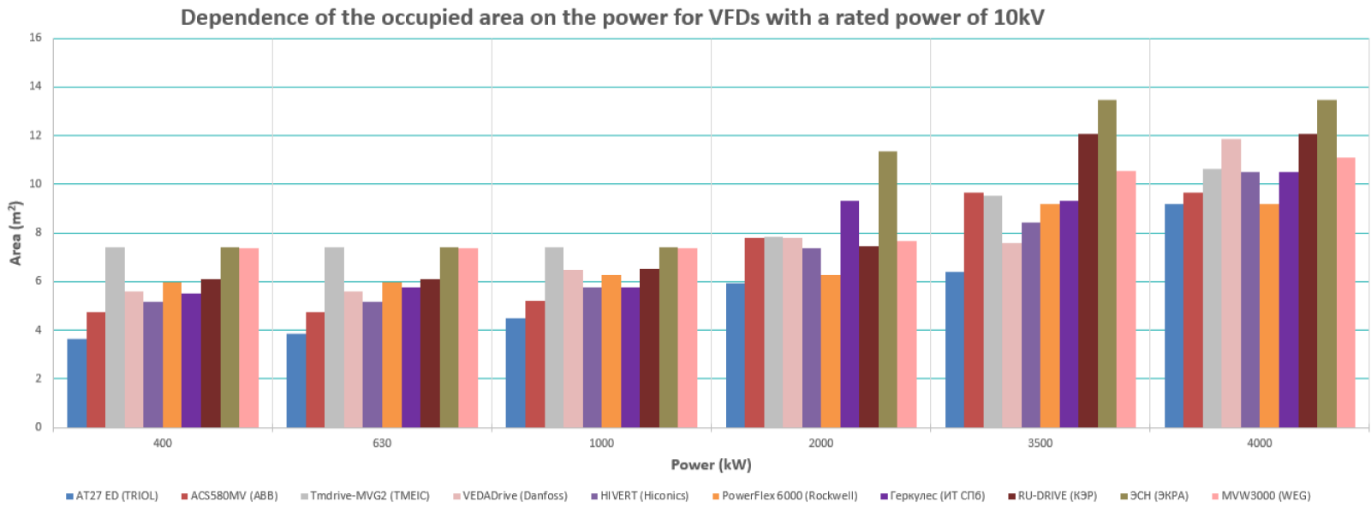

8.Placement in confined spaces.

9.Adaptable to local ventilation and equipment maintenance possibilities

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google