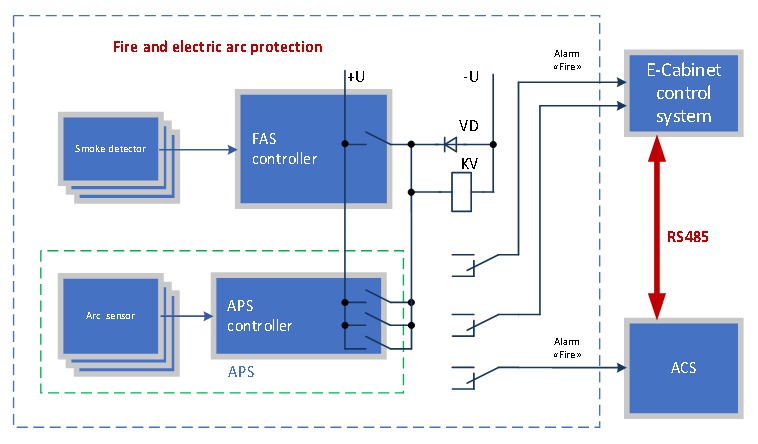

According to the U.S. Energy Information Administration, in the period from 2005 to 2015 the share of oil produced on oil platforms was on average 30% of global production (Fig. 1). The German company Statista expects this trend to continue until 2025.

Figure 1 - Ratio of onshore and offshore oil production

A key element in the oil production process on offshore platforms is the equipment that ensures the technological operation of the submersible unit, specifically the frequency drive and related transformers (step-down and step-up transformers). The equipment has high standards, such as:

- low input and output THD;

- rust resistance;

- minimum dimensions;

- minimum weight;

- reliability;

- fire protection;

- non-stop operation;

- wide range of connectable motors;

- easy and quick setup when handling the equipment;

- equipment autonomy operation in case of emergency situations; and

- easy and fast equipment maintenance.

Triol Corporation offers a solution to meet a wide range of challenges that the offshore platform environment requires of its equipment.

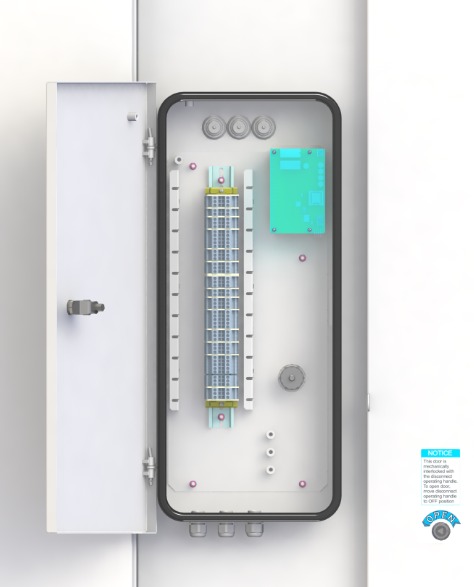

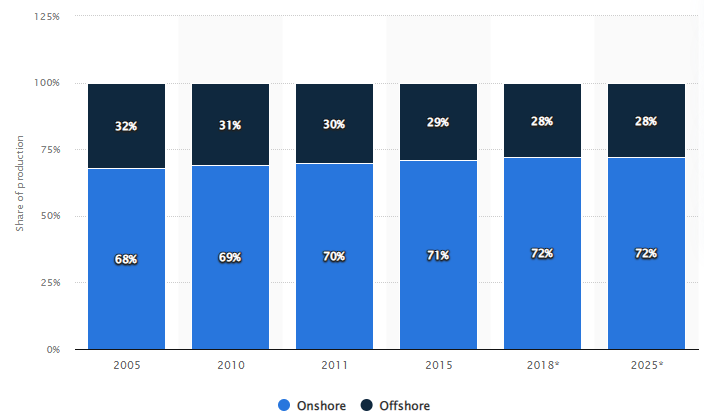

Triol E-Cabinet is a specialized compact solution combining in minimal dimensions a step-down phase-shift transformer (SDT), a frequency drive, and an output step-up transformer (SUT). The solution ensures reliable and durable operation of the equipment due to unique technical solutions (Fig. 2, 3).

Figure 2 - Exterior of the Triol E-Cabinet

Figure 3 - Basic elements of the Triol E-Cabinet

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google