Why do we expect wonderful opportunities from the variable speed drive? Because the VSD is the most intelligent part of the entire system in an oil production unit. The Variable speed drive standing on the well accumulates most of the data for organizing the operation of the system. It is in the VSD that numerous control systems for parameters and automated responses to emergency situations are implemented. It is in the VSD that power cables from the well and from the electrical network converge, with the VSD remotely, rather than with a person locally, whose time is precious, and whose safety is priceless.

The precise choice of the VSD enables the manufacturer to:

- ensure the safe work of personnel at the well,

- maximize production,

- reduce investment,

- reduce production costs,

- reduce the load on the power grid,

- increase the run between repairs of submersible equipment,

- organize the mining process.

For an oilfield service company, the right choice of VSD will result, in addition to the above, with the possibility of:

- preparing your personnel for the launch of any type of well,

- reducing your costs and increasing the return on equipment service,

- getting a reliable partner for solving the manufacturer’s various technological and technical challenges.

Triol AK06 variable speed drives were designed by our company to solve each of the problems described above simultaneously. In this article we want to describe how Triol AK06 VSDs allow our customers and users to achieve their goals in the most profitable way.

1. Safety of personnel working at the well and in the shop.

The first important task of Triol AK06 is to organize the work of personnel at the well in the safest way. Triol AK06 was created considering personnel safety at every step, in every action and in every thought of the user. All AK06 VSDs provide user protection at several levels:

1.1. Mechanical protection:

- Structural division into hazardous voltage zones (power cabinets) and safe voltage zones (user cabinets)

- A mechanical interlock prevents the doors to the power cabinet of a running VSD from opening. Only custom bays are available

- Automatic shutdown and voltage reduction in the DC link in case of targeted unauthorized access to the VSD power cabinet during operation.

1.2. Basic software protections:

- Disconnection of the submersible electric motor in case of a voltage deviation in the main, if this deviation leads to an unacceptable overcurrent with the possibility of restarting after voltage recovery

- Shutdown of the submersible electric motor at underload (protection against power outages)

- Shutdown of the submersible electric motor at maximum current load (maximum current protection)

- Shutdown of the submersible electric motor in case of overheating of the power modules

- Shutdown of the submersible electric motor when the set parameters of the DMS are exceeded

- Shutdown of the submersible electric motor in case of unacceptable pressure in the pipeline (according to the signals of the contact pressure gauge)

1.3. Intuitive protection (information protection):

- Light indication of dangerous voltage signals the presence of high voltage

- Warning signs are placed where there is a risk of electric shock

- Protective glasses prevent accidental and reflex touches to current-carrying power elements

- Emergency stop button that provides immediate shutdown in the event of an abnormal situation.

1.4. Safety certifications.

The enclosure of the Triol AK06 variable speed drive allows the use of this equipment in a hot desert climate and has been confirmed by the EN 60529 standard since 2013.

AK06 has also successfully passed the EMC EN 61439, EN 61000 certification since 2017, which confirms the low impact of the VSD on the power system.

In the Triol AK06 model range there is also a VSD line that meets the safety and quality requirements of the UL61800-5-1 standard. In this line of variable speed drive, materials with increased fire resistance are used, in addition to enhanced explosion protection of the case.

1.5 Approvals for operation from world manufacturers.

Triol AK06 VSDs are operated at the fields of almost all world oil producers in countries such as: USA, Saudi Arabia, Russia, China, India, Oman, Kuwait, Iraq, Egypt, Libya, Sudan, Congo, Nigeria, Turkey, Romania, France , Argentina, Peru, Colombia, Venezuela, Ecuador, Mexico, Indonesia, Thailand, Vietnam, Ukraine, Kazakhstan, Belarus, Azerbaijan, Uzbekistan, Georgia and others. We are glad that AK06 is used by almost all oilfield service companies in the world in their projects in 2020.

The use of our equipment in different countries and in different operating conditions allows us to integrate the experience of manufacturers and service providers all over the world. We carefully study this experience and integrate, creating new generations of solutions in the areas where it is needed.

2. Maximizing oil production at each well.

2.1 Complex protection of the installation against overvoltage: lightning protection.

When we talk about maximizing oil production, the first thing we associate with it is operating time (or equipment downtime if we look at it from the other side). User requirement – 0 hours of equipment downtime per year. That is why it is so important to guarantee the stability of the VSD, which in turn ensures the operation of the entire installation. One of the most common problems for oil companies is network overvoltage. They can arise both due to technical problems in the power system, and due to natural phenomena – lightning.

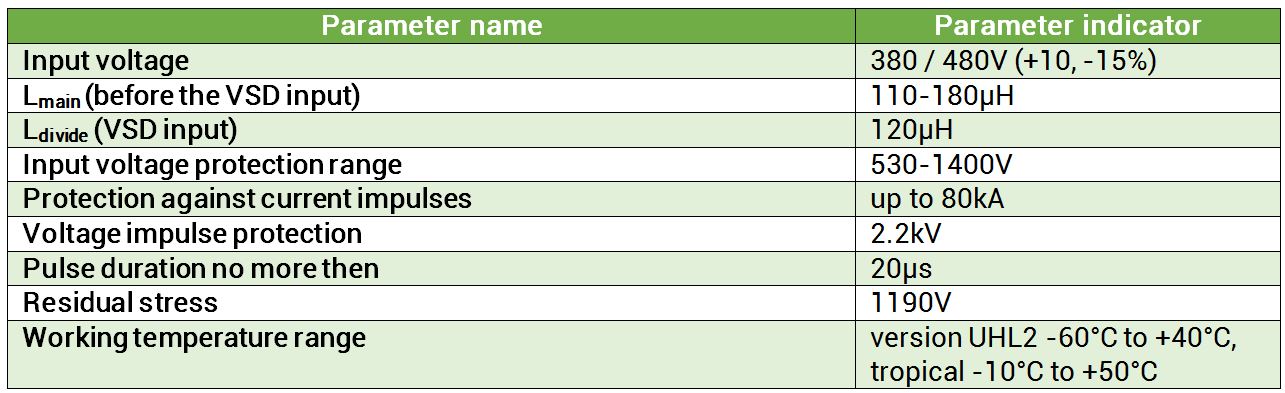

Triol AK06 can be optionally equipped with comprehensive overvoltage protection, which will allow petroleum company and NDC to forget about constant equipment stops due to overvoltage reasons. Data recording is carried out automatically in the controller of the VSD. This will allow the oilfield services company to calculate the cost of ownership through an increase in oil production. The table below shows the technical characteristics of the lightning protection option.

2.2 "Advance payment" mode: work in mains with voltage dips up to 0 Volts.

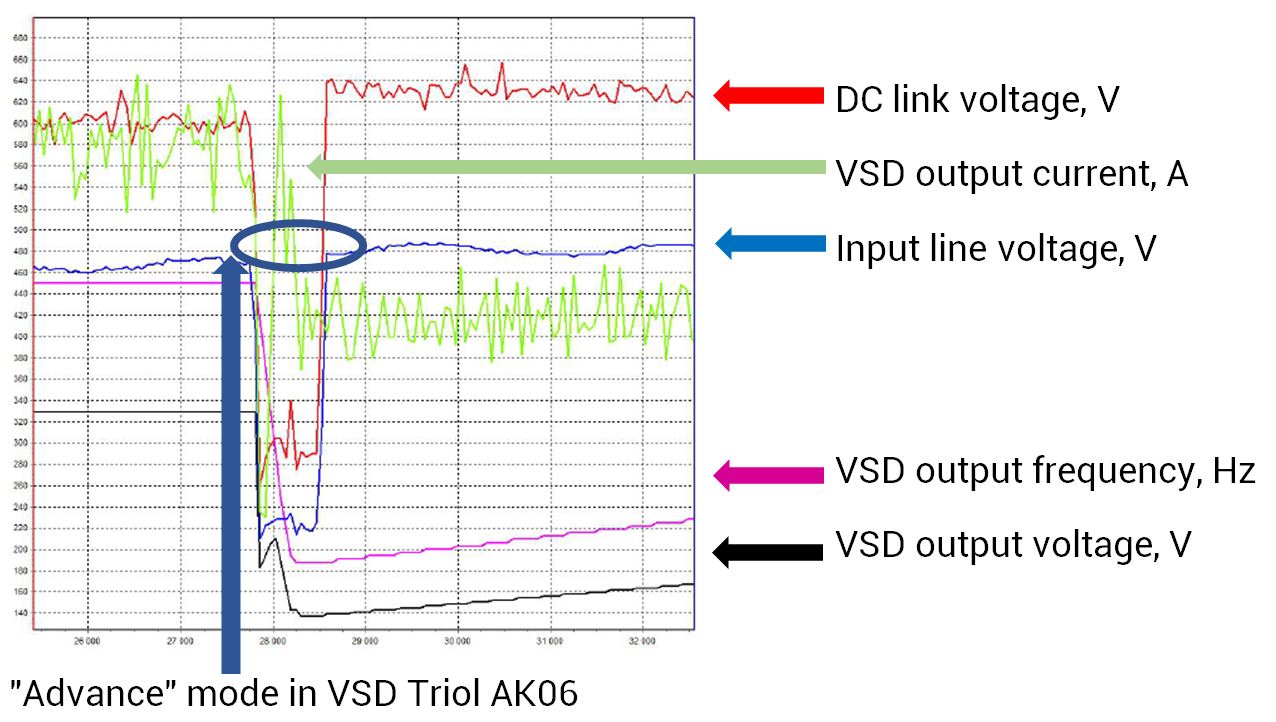

The second problem of the supply voltage is the reverse – it is the regular dips in the supply voltage. "Advance payment" is a unique function of the Triol VSD management, based on a special work algorithm. In case of voltage dips in the input main, Triol AK06 leaves the ESM in operation by using the kinetic energy of the motor and transferring the motor to the generator mode of operation. This algorithm allows you to maintain control over the installation in case of short-term dips in the mains voltage and ensures continuous production in conditions of unstable power supply, characterized by voltage dips to zero. The graph below shows how this algorithm works.

“Advance” mode: Triol AK06 operation during input voltage dips. As can be seen from the graph, during the drop in the input voltage, the VSD continued to control the motor, and after recovery, the VSD continued to increase the output frequency to the specified frequency.

2.3 Algorithm for passing gas jams.

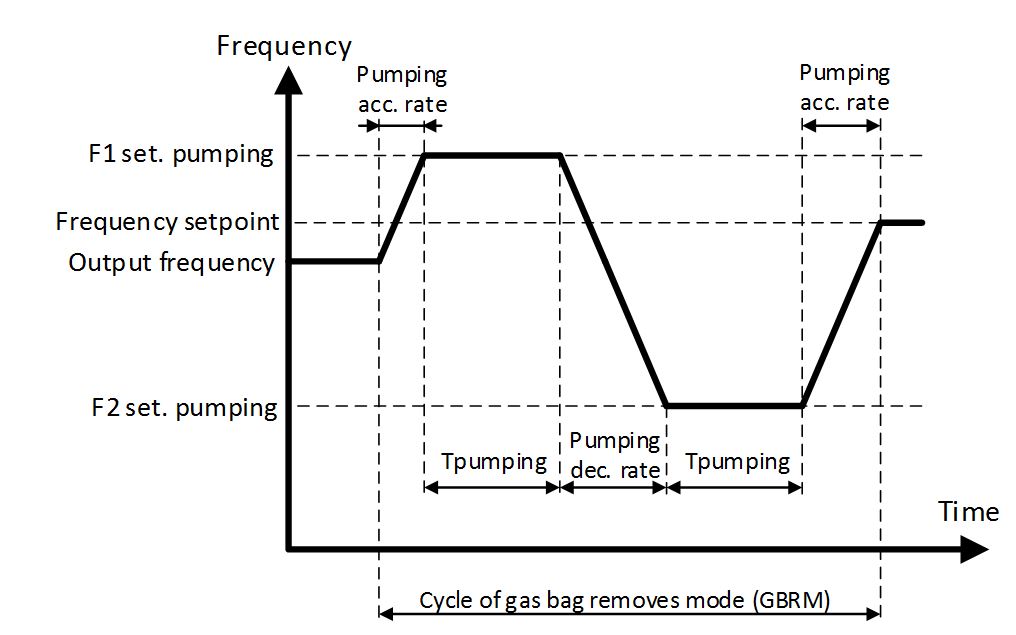

Another reason for stoppages in oil production is a decrease in motor load due to gas contamination of the well. To maintain continuous operation, Triol AK06 provides an algorithm that allows cyclical changes in the operating frequency of the installation. This algorithm is activated automatically when detecting a decrease in the motor load below the value set by the user, and the algorithm will exit if the load is restored or all pumping cycles are completed. The figure below shows the graph of the algorithm and its settings.

2.4 Modes of interlocking installation.

Another possible reason for stopping oil production is a jammed submersible unit. To wedge the motor, several start modes are provided:

- The mode for ensuring the maximum torque at a low speed. When starting a submersible motor in this mode, after accelerating the motor at a frequency dependent on the slip frequency of the motor for 2 seconds, turn on the current regulator, which will ensure the rotation of the motor at a given frequency while maintaining one and a half rated voltage. This will provide maximum torque at low frequency. In the future, overclocking will occur in the usual way.

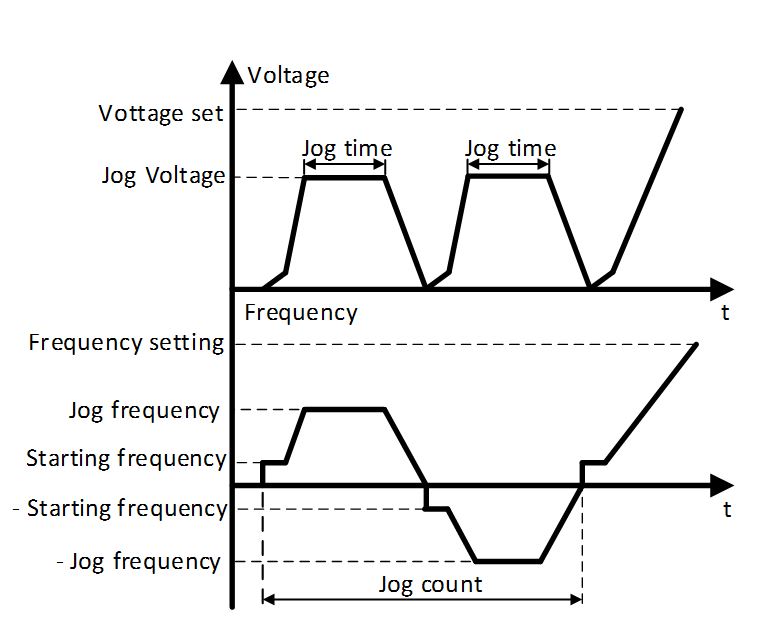

- Swing start mode - the VSD is started by jolts with different directions of rotation. Before accelerating, the motor will be pulsed with a user-defined voltage and a user-defined frequency. It is possible to independently set the number of swing cycles manually. The diagram below shows the algorithm for this mode.

3 Reduced investments in well equipment.

3.1 Variety of models and adaptability to all known climatic operating conditions.

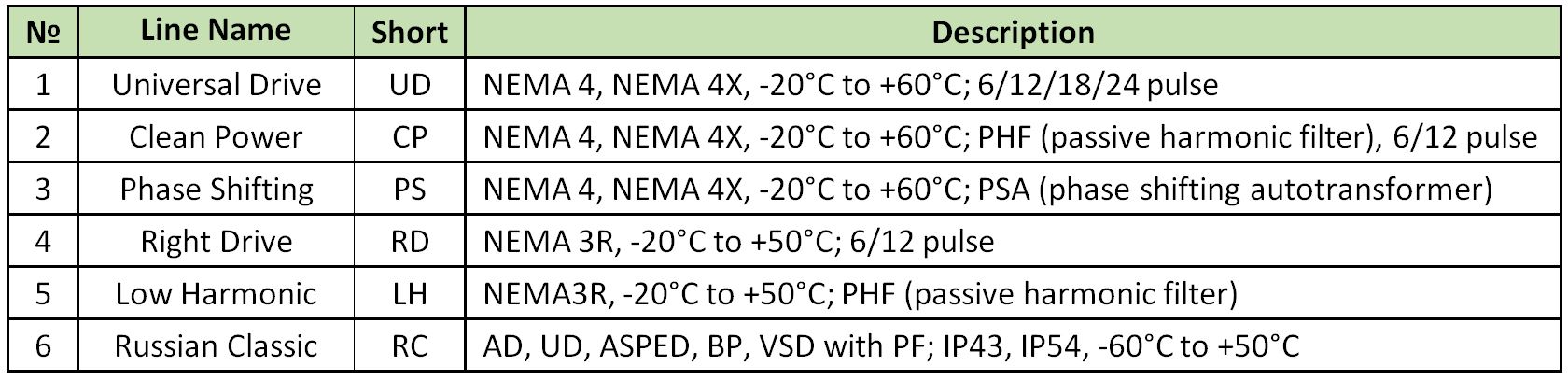

Triol AK06 VSDs are available in a wide range of 6 lines, which offers the opportunity to choose the right equipment for different regions of the world and operating conditions. The variety of the Triol range allows you to optimize your investments both at the stage of selection and procurement of your chosen Triol VSD, and during long-term operation due to the rational cost of ownership.

Each model of AK06 VSD can be integrated into almost any installation of any global manufacturer of submersible equipment due to its versatility. The correct choice of the VSD allows you to operate it in your climatic zone, including:

- zones with a moderately cold climate

- tropics

- desert

- maritime climate (CS placement on offshore platforms).

The variety of lines, shells, and operating temperatures of AK06 VSDs are shown in the table.

Since various models of VSD are operated in different regions of the world, they have many additional universal parameters, which makes it possible to integrate control systems without problem. Let's take a closer look at all the parameters.

3.1 Rated voltage of the control system: from 380V to 690V.

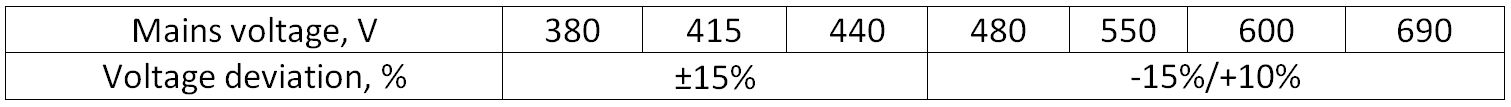

Triol AK06 VSDs have several versions and can be used in networks with voltages from 380 to 690V. The accepted rated voltage of the network varies depending on the power system of a particular region of the world market: 380, 415, 440, 480, 550, 600 and 690V. The operating values of the supply voltage deviation for the AK06 in each power system are shown in the table below.

In this regard, the AK06 model range allows the buyer to select the desired operating voltage, which allows the control system to be built into the equipment that petroleum company and NDC already have, thereby not leading to additional costs for transformers and providing a low total cost of ownership of the installation when upgrading it.

3.2 Rated load current: 100A to 3200A.

The power of AK06 VSDs is expressed not in kW, but in terms of the rated current (A). Since the operating voltage has at least 5 variations, respectively, the same control system can produce different output power at different input voltages. We have formed the active current range based on more than 20 years of experience with various installations, and today this range varies from marginal wells, for which a 100A control system is suitable, to true giants in terms of the amount of oil, which requires a VSD with a capacity of up to 3200A. We have developed such a wide portfolio of proposals so that every oil or oilfield services company can find the optimal solution for any type of well and can use its investment in well equipment wisely.

3.3 Output voltage: not less than 95% of the input.

The formation of the output voltage is performed according to the vector pulse-width modulation algorithm, the main property of which is a constant change in the potential of the common point of 3 output voltage vectors relative to the negative potential of the DC link. The algorithm allows you to form the output voltage in relation to the input at a level not lower than:

- 98% for a VSD without built-in output sine filter

- 95% using an output sine filter in the VSD + using an algorithm for increasing the effective output voltage

- 92% using an output sine filter in the VSD.

This will allow you to get the maximum power of the installation and the minimum investment losses from the loss of power of the installation in the VSD and sine filter.

Additionally, Triol AK06 recommends the amount of tap that should be set on the step-up transformer (for submersible installations) to ensure sufficient voltage at the motor terminals at the operating frequency of the installation.

3.4 Vector control of valve motor – maximum available torque on the motor shaft.

To control submersible electric motors with permanent magnets (permanent magnet motors), a highly efficient vector control method is implemented in AK06 VSDs, the cosine of which tends to 1 with the minimum required power consumption. The high efficiency of the method is achieved by implementing motor control considering the current position of the rotor. The rotor position is determined mathematically, without the use of additional sensors.

The work on the position of the rotor allows you to design the motor control in such a way as to ensure the most stable operation of the motor at a given frequency with a load due to the current characteristics of the pump and the formation at the maximum torque on the motor shaft that is possible for a given installation and under given conditions in the well.

Maximum stability and minimum consumption are achieved by high accuracy in determining the position of the rotor, which in turn is ensured by the work of our algorithms:

- Determination of the electrical parameters of the motor

- Determination of the moment of inertia of the installation

- Calculation of the current rotor position.

For the convenience of the user in the vector control mode, the following algorithms have been developed:

- Automatic calculation of regulator parameters

- Start-up with automatic adjustment of the starting torque

- Seamless transition to vector control mode.

All this together will allow you to minimize your investment in ESM while reaching the target capacity of the entire installation.

3.5 Additional options: AK06 is not just a VSD, but a technological system.

AK06 variable speed drives can be equipped with additional options, which will allow the customer to improve the quality of control, management, well ownership and expand the number of technological tasks to be solved.

The variety of options for Triol AK06 are divided into categories:

- Options for each control system separately to expand the user's functionality, protection, and monitoring of the installation as a whole.

- Options of spare parts for delivery in a set for any number of control systems. There is the option of purchasing both a standard set of spare parts and individual spare parts for each user. This convenient solution allows oilfield service companies to conduct business more flexibly and to select the spare parts and accessories that will be most effective at specific fields.

A set of options for the implementation of turnkey projects. Here Triol offers products of its own production such as:

- SKID with IP20 or NEMA 4 enclosure for placement inside customer's equipment (VSD, transformers, distribution boxes, operator's compartment, etc.)

- TM01 - Triol submersible downhole system

- EP01 - installation of an electric plunger pump

4 Reduced production costs.

4.1 The reliability of the AK06 is close to 100%.

One of the main requirements that we place on AK06 VSDs is their reliability. We understand how important it is for our customers to work with equipment that will ensure stable, uninterrupted oil production. We achieve high reliability rates due to:

- Designing products considering all the features of the customer's operation

- A full cycle of production of our own electronics blocks, coil products, cells, and housings

- Skillful incoming control of all components, not only according to the parameters in the manufacturer's data sheet, but also based on many years of cooperation with them

- Operational control at all stages of production

- Comprehensive simulation tests confirming the product's performance during the warranty period under specified operating conditions

- Checking the performance of products in the limiting modes of operation (maximum deviations in voltage, current, frequency, and temperature).

Triol AK06 test base is a high-precision automatic heat cabinet, IP test cabinet for water, IP test cabinet for dust, transport test stand, and endurance test stand for electronics units.

4.2 Current optimization mode in Triol AK06: gain - up to 10%.

After pumping out the killing solution and reaching the steady-state operating mode of the submersible installation, it is important to select the optimal voltage at the output of the step-up transformer in order to minimize the power consumption of the installation and maintain the target flow rate. As a rule, the selection is carried out by stepwise voltage decrease, i.e. by switching the taps of the step-up transformer. Because the taps cannot be switched while the submersible equipment is running, the VSD makes it possible to automatically adjust the optimal voltage. The criterion for optimal voltage is the minimum operating current of the motor. Automatic selection of the optimal voltage makes it possible to select the optimal motor voltage depending on the motor operating conditions. Automatic selection is performed cyclically at a predetermined time interval after setting the operating frequency and / or after changing the motor speed. This mode saves up to 10% of the electricity consumed by the entire installation.

4.3 Reducing electricity consumption in vector control mode: gain - up to 25%.

The second important quality of vector control implemented in AK06 for controlling submersible electric motors with permanent magnets (permanent magnet motors) is that the cosine F of the ESM with this control method tends to 1, which provides the minimum required power consumption. The work on the position of the rotor allows you to build the motor control in such a way as to ensure the most stable operation of the motor at a given frequency with a load due to the current characteristics of the pump and the formation with minimal energy consumption. This allows you to save up to 25% in electricity when using Triol AK06 VSDs with valve motors when compared to almost all other global manufacturers of ESM.

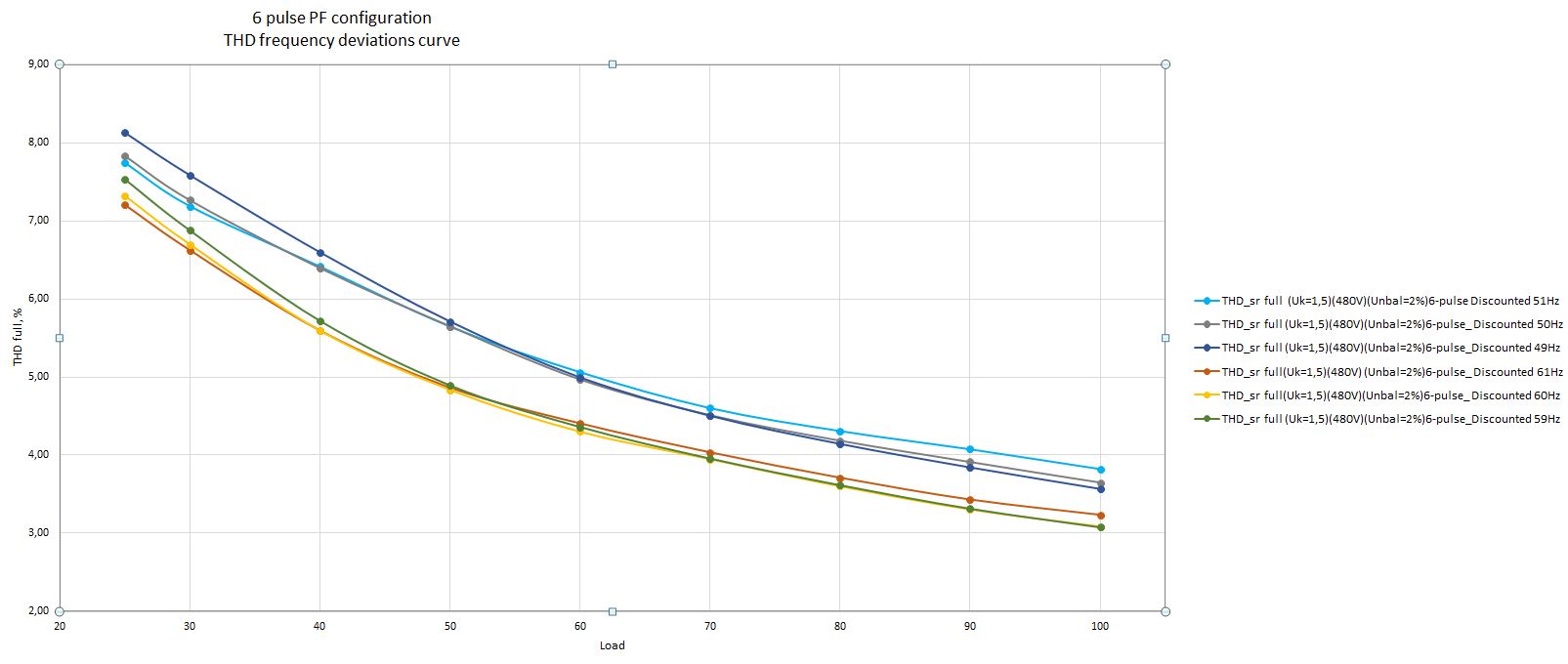

5. Reduction of load on the power grid: THD at the VSD entrance - less than 5%.

Triol paid special attention to the problem of total harmonic distortion (THD). The problem of distortion nonlinearity in the network will already begin to hit the user's wallets during the design of the installation. With a THD of more than 5%, the effective value of the current in the network increases, which for the end user is fraught with the selection of unnecessarily powerful equipment, and, accordingly, this is an ineffective waste of funds. The next step in the impact of poor THD is equipment downtime due to false trips. And in the end, all this affects the service life of the equipment as well as service costs.

High electromagnetic compatibility of Triol AK06 VSDs with the supply network is ensured by using either passive input filters (PF) or phase-shifting transformers, depending on which transformers are used at the customer's field.

CP and LH VSD lines, with built-in passive filter and special software in the complex, provide the parameter THD input ≤ 5% in the range of input currents of the rectifier(s) of the VSD from 25% to 100% of the active current in the control system of the CP line. The specified result is achieved by the TS for the power section and the control algorithms of the PF.

AK06 VSDs with built-in PF eliminate the customer's problems with the quality of the supply voltage. Moreover, there is no need to use additional devices for reactive power compensation and / or filtering of higher current harmonics, the introduction of which at facilities is accompanied by additional costs for work on the analysis of power quality. The graph below shows the dependence of the change in the THD of the input current consumed from the power system on the output load of the Triol AK06 VSD.

In addition to the nominal dependence curves for a main of 380V 50Hz and 480V 60Hz, dependence curves with a deviation of the main frequency of ±1Hz are shown.

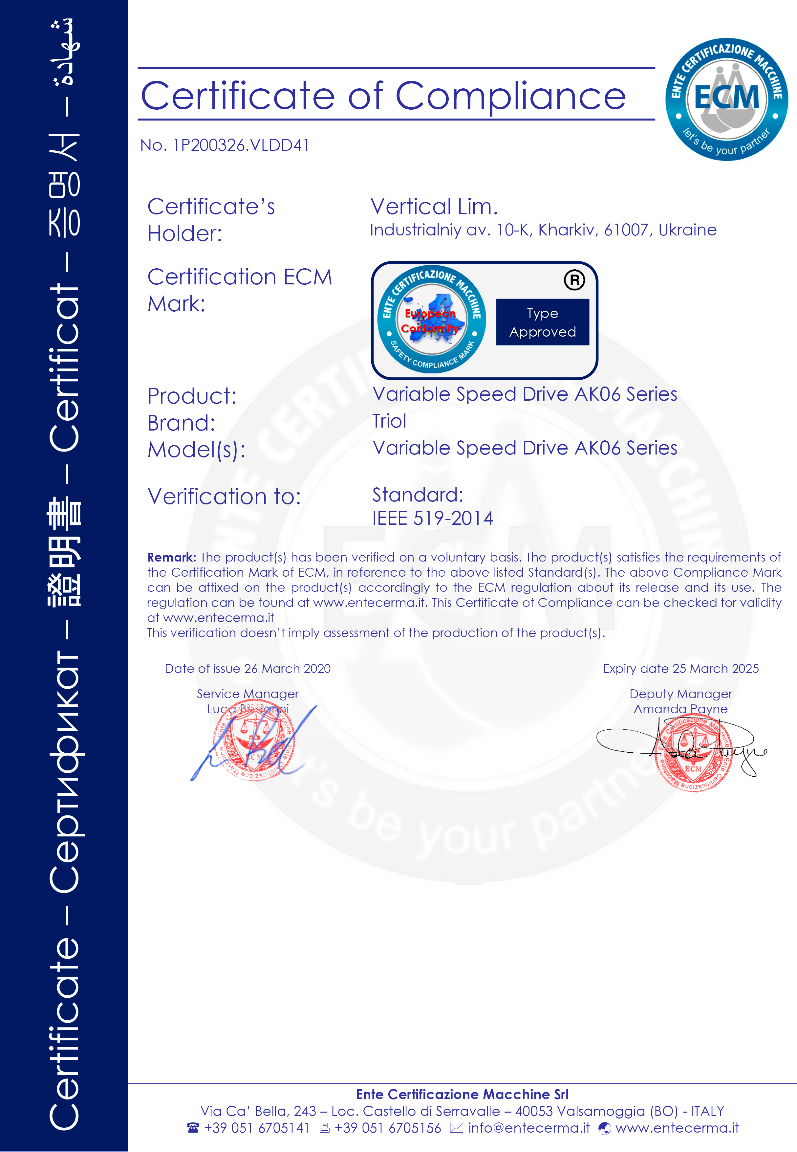

This advantage of Triol AK06 VSDs is reflected in a special certificate for compliance with the requirements of the IEEE 519-2014 standard for harmonic distortion.

6 Increasing the run between repairs of submersible equipment: sine filter in 100% of models.

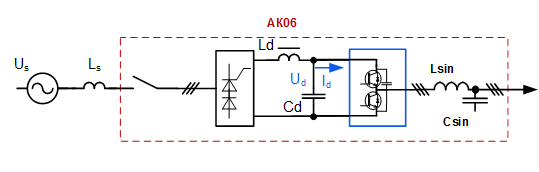

Triol AK06 are power voltage inverters based on IGBT transistors, in which the energy of a three-phase power supply voltage of an industrial frequency is converted into three-phase voltage of variable frequency using PWM methods. The standard load of voltage inverters is motors – asynchronous (with an operating frequency of up to 80Hz) or valve (with an operating frequency of up to 600Hz).

In the oil industry, the inclusion of an intermediate step-up transformer between the VSD outputs and the motors is widely used. The use of high-speed power switches (IGBT transistors) with on / off times at the level of fractions of a microsecond leads to the appearance of high-frequency noise at the outputs of VSDs.

Sinus filter (SF) is a universal technical solution (TS) of Triol AK06 VSDs. SF ensures full electromagnetic compatibility of VSDs with load motors when directly connected or working through an intermediate transformer, which increases the duration of the submersible equipment. Tuning the resonant frequency of the SF below the frequency of the PWM speed drive allows you to "clear" the spectrum of currents and voltages at the output of AK06 from higher harmonics, without additional efforts on the part of the customer.

Block diagram of the Triol AK06 power unit with SF.

SF are used in the entire current range of VSDs from 160A to 3200A. Special versions of SF are used in Triol AK06, designed to work with output frequencies of 300/400/600Hz.

7 Organization of production process management.

As one of the main attributes of the most intelligent part of the entire installation, AK06 VSDs have a high degree of integration into the oil production process.

First of all, the VSDs implement the mode of maintaining the technological parameters (pressure, temperature, current, etc.), the mode of operation according to the time program, according to the timer, automatic and manual modes, and the ability to start the control system only remotely, only manually, or jointly.

AK06 VSDs support telemetry systems from leading world manufacturers. Supported telemetry list: Triol, GRC, Zenith, RMSpumptools, Oxford, Phoenix, ACE, Uniconn, Novomet, Borets, Centrlift, Viewpoint, Solvapi. Moreover, the VSDs have the functionality of adding any new DME independently by the user. The DME is connected via one of the channels: RS-485 or RS-232. The VSD has a unit for powering the telemetry unit from 230V 50Hz or 120V 60Hz.

The next confirmation of the above is a wide range of possibilities for connecting analog and discrete sensors with subsequent processing of information received from them. The number of available inputs and outputs of the controller will be able to cover even the most demanding and precise technological needs, because in the maximum configuration AK06 has:

- up to 24 analog inputs

- up to 14 discrete inputs

- up to 8 analog outputs

- up to 6 digital outputs.

The number of peripherals is negotiated separately when ordering. The Triol AK06 also performs the reverse task, namely, it transmits the collected information from the entire installation via the SCADA channel to the operator's control panel. AK06 can perform this task on any of three exchange interfaces:

- RS-485

- RS-232

- Ethernet.

It is also possible to optionally equip the AK06 with a communication modem and get rid of wired data transmission. The final important function of the process control is the storage and analysis of the received data for a certain period of time. AK06 solves this problem by maintaining a log, which reflects all operator actions or automatic control system actions, data from all peripheral nodes, and current motor values. The user can manually set the frequency of data recording in the event log, and, using a special service application on a PC, it is convenient and simple to analyze the behavior of the installation.

8 Professional training of oilfield service company personnel to work with Triol AK06.

The AK06 VSDs are designed to minimize the efforts of engineers and specialists in storage, unpacking, incoming inspection, commissioning, and handling of the series products. In particular, we have provided the following distinctive features in Triol AK06:

- Eco-friendly packaging material complies with international phytosanitary standards ISPM15, while providing full protection of AK06 VSD from moisture and rain even in the harshest oil production areas, and reusable packaging saves costs.

- Product labeling meets international requirements ANSI Z535 and allows staff to quickly master the product. Convenient location of AK06 VSD information signs ensures personnel safety when working with equipment.

- The "brain" of the AK06 – the Triol UMKA07 controller – has an intuitive interface and allows you to perform work efficiently and quickly from the first minutes during incoming inspection or putting the equipment into operation.

- Modes of starting motors, protection, telemetry or modem settings and other settings can be done without leaving the car using the Triol Wizard, thanks to the built-in Wi-Fi function.

However, we appreciate the work of the engineers and technicians who operate and service the AK06 all over the world. To prepare them, we have developed several training programs. Depending on the depth of product knowledge required, we train product champions, application engineers and field engineers.

AK06 has a complete set of documentation, which clearly and concisely describes all steps in the design, commissioning, and maintenance of the product. Using the QR code, the operator at the well has direct access to the services of Triol Corporation, which will immediately provide answers to various questions.

When performing repair work on the AK06 VSD, service personnel have access to the Troubleshooting Manual, where they can find answers to questions about diagnosing faults, replacing warranty parts, as well as a description of the required tools and step-by-step instructions.

Together, this allows us to prepare your staff for reliable and inexpensive operation of the Triol AK06 series of products.

9 Reducing the cost of an oilfield service company when working with Triol.

Another reason why the AK06 VSD is a good choice also lies in the favorable cost of possible repairs. Reasonable cost of repair or modernization of the Triol AK06 is ensured by the modular design. This allows you to repair only the block or unit that is out of order, maintaining a balance between the price and duration of the repair.

In AK06 we use components from both our own production and world leaders in the field of electronics, therefore, if necessary, many components can be purchased from us quickly from anywhere in the world.

10 Product customization and solving your problems.

The AK06 product has stood out for its versatility since its inception in 2002. For almost 20 years we have solved many unique problems and today we continue to improve the technical solutions of the series, adapting them to new market conditions.

In fact, today the Triol AK06 series is a design that allows you to create customized solutions for unique applications from its component parts in a short time. For example, a customer needed a NEMA 4X VSD with highly corrosive materials combined with a 24-pulse rectifier or low harmonic filter. This solution allows the customer to use AK06 in an offshore platform and demonstrate high specific efficiency of consumed electricity.

Another customer was looking for a VSD that would drive a brushless motor up to 660Hz and would be approved for use by most of the world's oil companies. Another customer would like to use his own, familiar to his HMI specialists, and we integrated his controller into AK06. Another customer was attracted by the shell of the AK06 VSD series, but at the same time wanted to use his chassis inside the VSD as a power unit. If you have a set of production facilities to produce casings, then AK06 turns into a kit for embedding into your casing. And so on. The production and quality management system of Triol Corporation has complied with ISO9001 since 2002. However, the change in the nature of production cooperation with our customers required changes in the Quality Management System, and today we control not only the production of products, but also the quality of engineering support of our production partners.

Thus, Triol becomes a technology partner for its direct customers, and together we solve the problem of creating maximum value for end users. Such work involves the online solution of emerging problems, both in production shops and at wells. All this allows us to continue to improve technical solutions every day, which, we sincerely believe, are the most advanced, reliable, and profitable in the industry.

We hope that in this short article we were able to convey to you our love for what we do, and we would be glad to cooperate with you. We are confident that, thanks to such cooperation, you will solve all your most difficult problems in the most beneficial way for you!

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google