As we mentioned earlier, Triol Corporation specializes in supplying complex solutions in the field of frequency control of powerful units driven by induction and synchronous electric motors.

This article provides answers to the following questions:

- What is a complex solution in the field of frequency control?

- What is its key difference from a solution that is not complex?

- What is the benefit to the consumer of using a complex solution?

What Triol offers as a complex solution. Triol’s complex solution is a set of hardware and software tools that allows the consumer to solve the challenge in full, at the lowest possible cost, without using other equipment and technical solutions from third-party manufacturers.

The essence of Triol Corporation's complex solution for the AT27 VFD is to supply not only a VFD, but also the following related equipment:

1. CB27 switching cabinets designed to

- Switching on the input and output circuits of the AT27 VFD.

- Bypass the VFD to operate the motor from the mains, when taking the VFD out for repair or scheduled maintenance.

2. CB27 reactor cabinet to limit the output current of the AT27 VFD when motor synchronous transfer from VFD to mains and vice versa (synchronous transfer from mains to VFD).

3. CB27 output sine-wave filter cabinet, providing "ideal sine" wave of the output voltage and current of the AT27 VFD (THD less than 2%).

4. Mounting kit, which is a set of control cables and power jumpers for connecting the AT27 VFD and switching cabinets.

5. RC27 remote control panel (RCP), designed for remote control of operating modes, displaying the current values of parameters and the state of the AT27 VFD.

6. SC27 automatization panel, intended for the organization of automated maintenance of the technological parameter values and the organization of technological equipment protection, control of external switching equipment, and communication with the ACS.

The above set of equipment allows you to:

-

Connect to the required number of motors, both for frequency control and for direct starting, to the existing connection points in the medium voltage switchgear.

-

Reduce the area of the premises for placing the required equipment due to the high degree of integration of switching devices in the CB27 cabinets. So, for example, CB27 with a facade width of 1000 mm allows you to place up to eight switching devices (contactors, disconnectors, earthing switches), while standard switchboards and switchgear contain from 1 to 3 switching devices at a price comparable to the CB27.

-

Eliminate the need for an external PLC to control switching cabinets thanks to the AT27 drive’s built-in plug and play function, which allows you to determine the configuration of the power section of a complete solution.

-

Eliminate additional costs and errors in the manufacture of third-party power cable jumpers and control cables for switching cabinets.

-

Neutralize the influence of the AT27 VFD on motors with a rotor made of all-metal forging, and the influence of long cable lines (> 1000 m) on the insulation of motors.

-

Eliminate current surges during transient processes during the transfer of the motor from VFD to the mains or transfer motor from mains to VFD.

-

Provide local control and maintenance of technological parameters without an external ACS.

These advantages distinguish the Triol complex solution from solutions related to the supply of VFD only, which do not solve the end user problem in full without performing additional work.

The benefits of this solution:

-

Reduction of costs for modernization and switchgear retrofit.

-

Reduction of capital construction costs.

-

Reduction in the cost of electrical installation.

-

Elimination of costs associated with replacing old motors with worn-out insulation.

-

Reduction or elimination of additional costs for automation.

Depending on the purpose, the CB27 cabinets consist of:

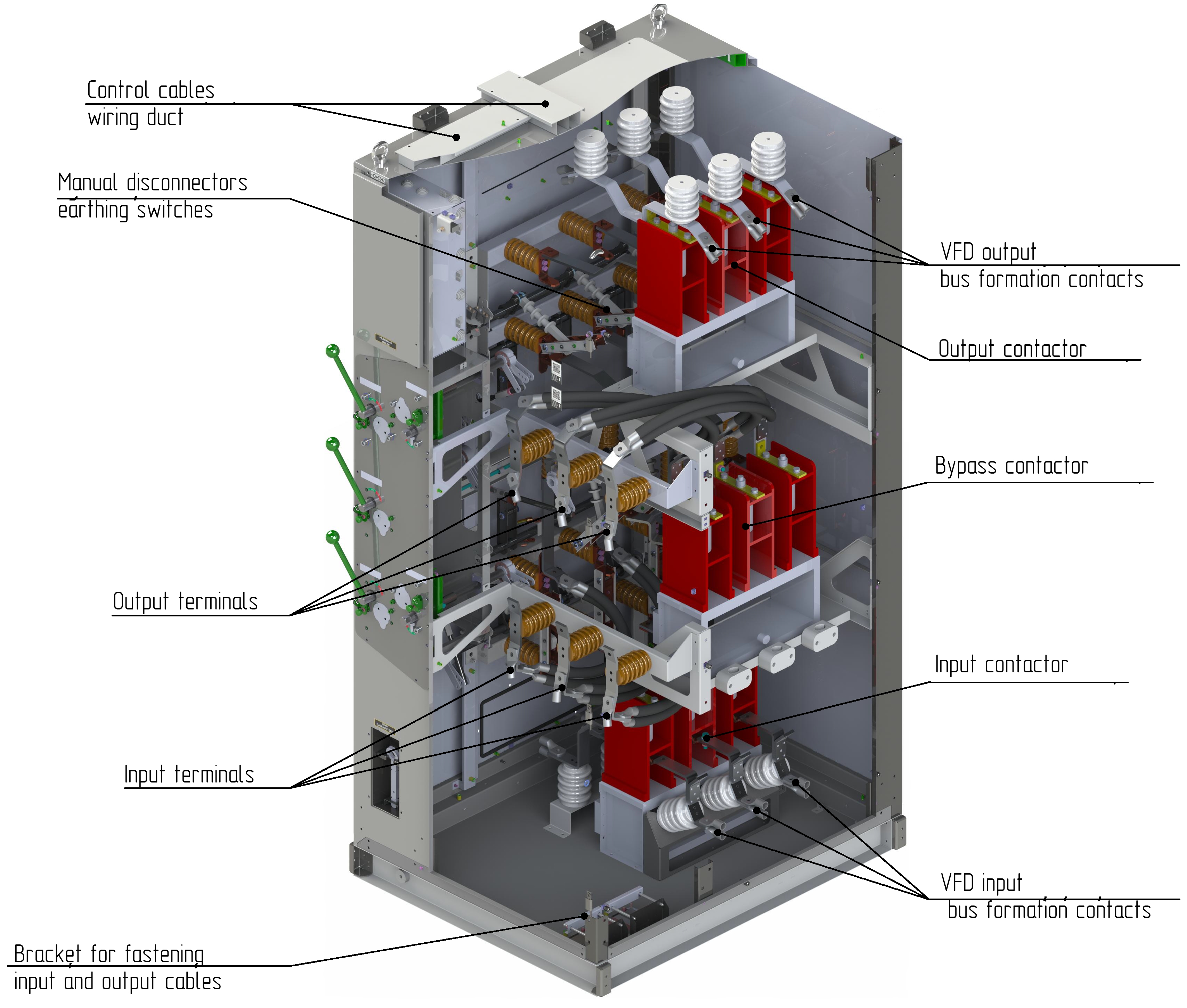

CB27 switching cabinet:

- up to three vacuum contactors: input, output, bypass, or up to two withdrawable vacuum circuit breakers with an operating voltage of the main circuits from 3.3 kV to 11 kV, with a rated current of 630 A, but at the request of the customer, it is possible to design for 1000 A and 1600 A,

- input and output terminals,

- manual disconnectors and earthing switches,

- surge arrester,

- control cables wiring duct.

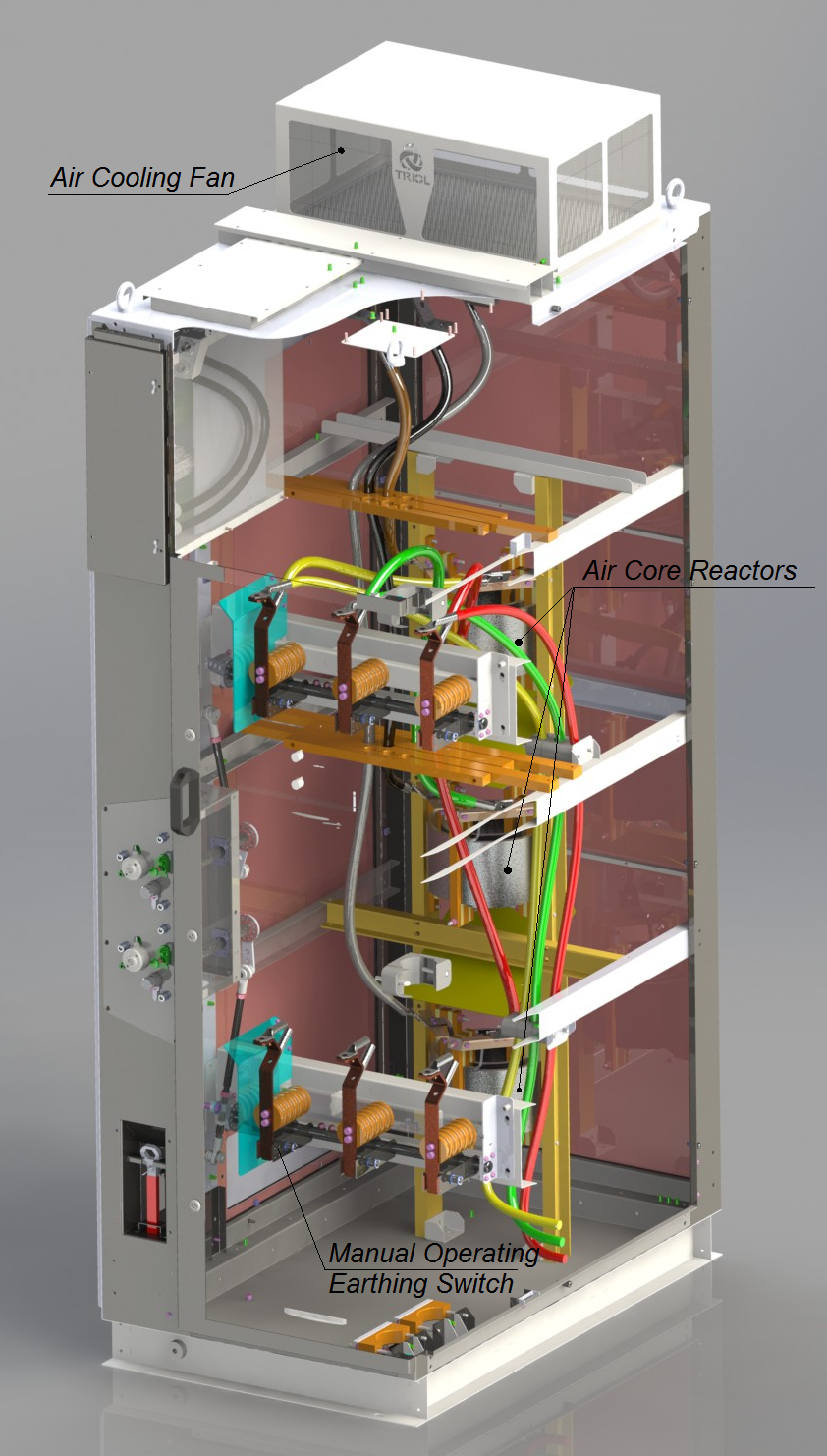

CB27 reactor cabinet and CB27 sine-wave filter cabinet:

- reactors,

- capacitor assemblies (only for the output sine-wave filter cabinet),

- manual earthing switches,

- cooling fan.

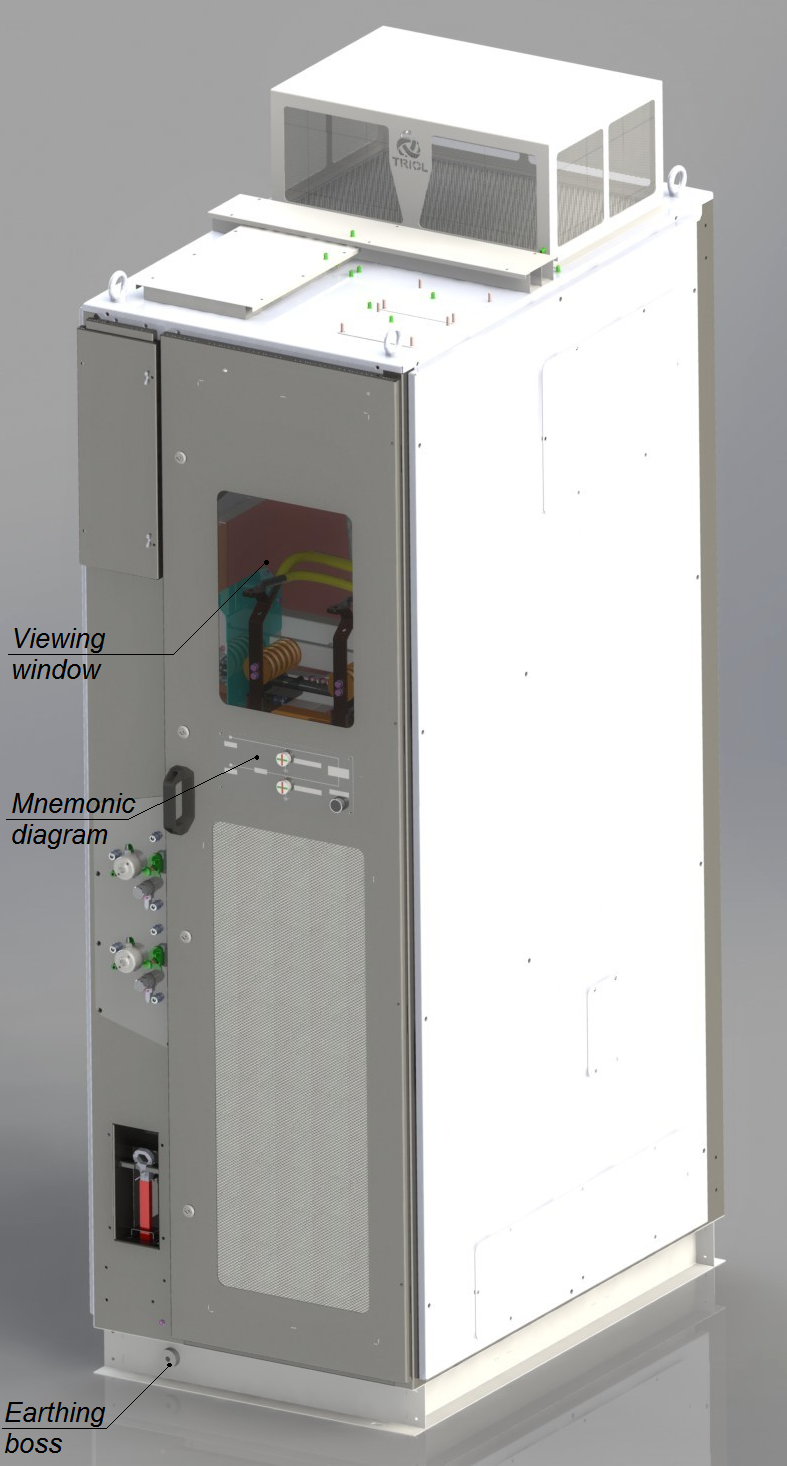

The operating voltage of the main circuits of the reactor cabinets and the sine-wave filter is from 3.3 kV to 11 kV, the output power of the VFD is up to 8000 kW. Triol Corporation considers the requirements of customers in the execution of the purchased equipment; for this purpose, the following options are provided in the design of the CB27:

- electromagnetic interlocks of manual disconnectors

- door locking with electromagnetic locks

- arc protection based on photothyristors

- IP31 / IP42 / IP66 enclosure

RCP27 remote control panel

An important component of a complex solution for the use of AT27 VFDs is a remote control panel (RCP) of the RC27 series. The remote control allows control of the AT27 VFD directly from the operator's workplace, which is of course convenient and creates comfort in the operating by the service personnel. The remote control panel allows not only the setting of technological parameters and control of the starting and stopping of the AT27 VFD, but also displays the current information about the state of the technological process and parameters of the AT27 VFD, such as current, voltage, output power, frequency, revolutions, etc., in a convenient format.

Depending on the requirements of the end user, the remote control panel can be designed as a wall-mounted or floor-standing push-button panel or color touch panel. The remote control panel can work simultaneously with six AT27 drives and with nine motors for each drive.

The convenient and intuitive user interface does not require special user training and provides multilevel access to the necessary user parameters for set-up, diagnostics, and equipment operation.

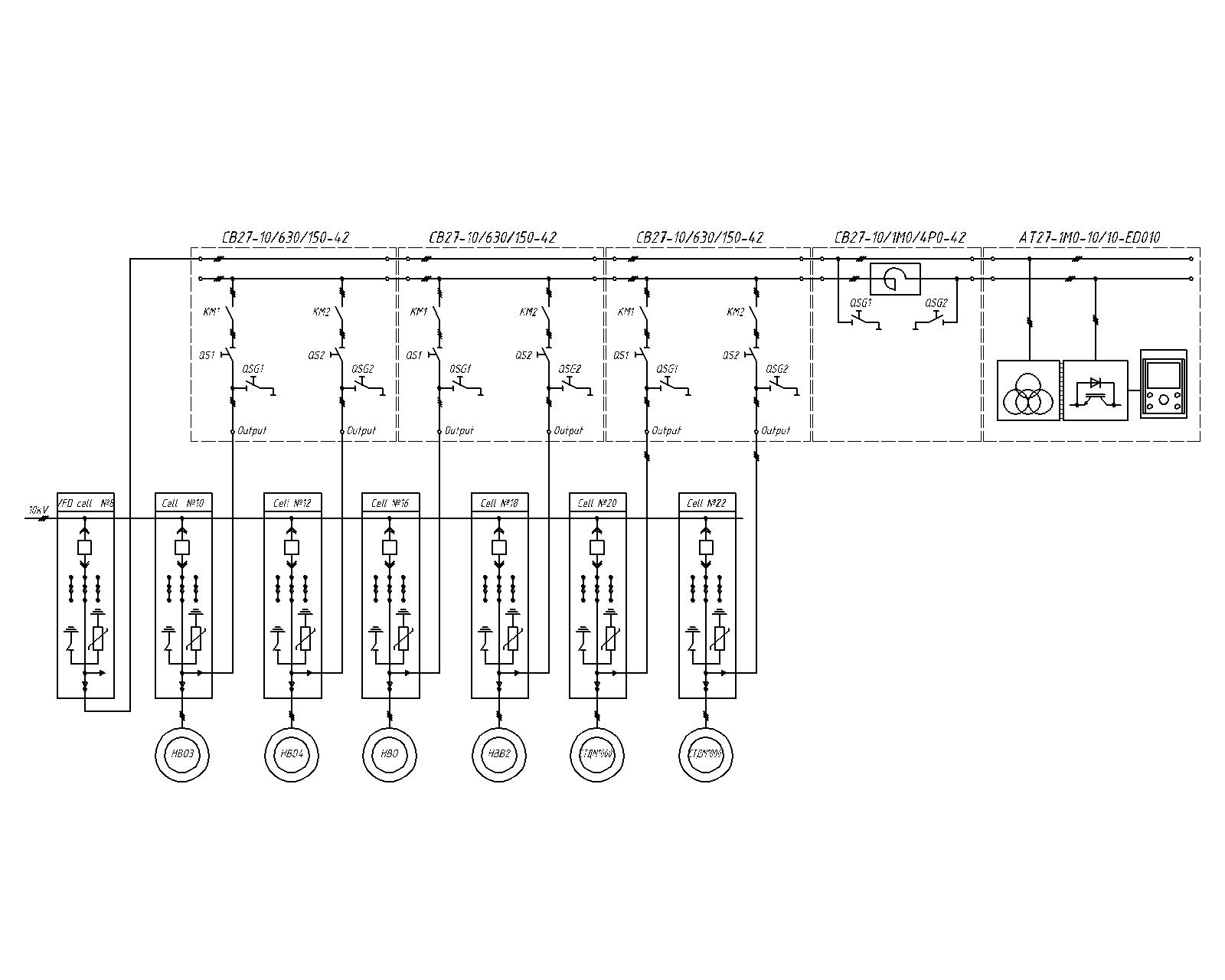

An example of a complex solution for the AT27 VFD As an example, consider the implementation of cascade control of 6 pumping units from one VFD, which provides frequency control of the selected pump, simultaneous motors transfer from VFD to the mains and motor transfer from mains to VFD. Such a complex solution is possible thanks to the use of the AT27 VFD together with three switching cabinets, CB27-10 / 630 / 150-42, which have the function of connecting the output of the AT27 VFD to one of the two motors, and the reactor cabinet CB27-10 / 1M0 / 4P0-42 providing AC drive AT27-1M0-10 / 10-ED010 when transfer motor from VFD to the mains or at the time of transfer from the mains to VFD.

The specified cabinets are optionally available with IP42 enclosure.

As can be seen from the complex solution, all switchgear which supply motors directly from mains remain used according to the old scheme; only one additional backup switchgear is necessary, designed to supply the AT27 VFD. For this task solving three CB27 switch cabinets and one reactor cabinet were required. When using a standard switchboards for this task would require six cabinets and a one reactor cabinet.

Depending on the switchboard series, the loss on the facade size can be from 600 to 3000 mm, which significantly increases construction costs. This is especially critical when there is very little free space in the allocated room and an additional 100 mm along the facade can force the end user to build a new room. Triol Corporation solutions minimize customer costs in terms of work related to connecting newly commissioned equipment to the existing switchgear, allow the integration of frequency control into the existing infrastructure of the enterprise without redoing the existing power supply scheme, which makes such solutions highly reliable and maintainable.

Conclusion:

Triol Corporation complex solutions for frequency control based on the AT27 VFD allow not only the costs associated with putting the equipment into operation to be minimized, but also the cost of equipment ownership to be optimized, and the problem posed by the end user to be solved in full without the involvement of third-party equipment and specialists.

Triol Corporation's proposals for a complex solution to the problems of end users are not limited to the examples given, we are constantly expanding the range of manufactured equipment, which allows us to increase our capabilities in solving our customers’ complex technological problems.

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google