As we mentioned earlier (read the article on the 14 advantages of Triol AT27 here)100% of the VFD elements can be tested with low voltage, which, in case of installation errors or other malfunctions, will not lead to a VFD failure.

The AT27 VFD series provides the possibility of mandatory full diagnostics and complete commissioning without load and medium voltage supply.

This solution favorably distinguishes AT27 from other VFDs of this voltage class.

Manufacturers of medium voltage VFDs aim at realizing the full diagnostic capabilities of equipment before connecting to the main. However, only Triol AT27 provides the ability to diagnose and test the operation of the product completely without applying medium voltage. Medium voltage supply can bear the risks involved with possible installation and commissioning failures.

With Triol AT27 this problem is solved in such a way that the installer can perform 100% of the commissioning and complete equipment diagnostics without medium voltage supply. Such a technical solution in the basic configuration of AT27 makes the VFD a 100% predictable element of the system when commissioning complex objects.

HOW THIS IS IMPLEMENTED

Obviously, you cannot perform the full scope of commissioning and complete diagnostics without medium voltage supply. A product or system is considered to be fault-free and ready for use if all components are in good operating order. Triol Corporation has solved the problem of testing Triol AT27 before supplying the mains voltage by artificially creating a medium voltage on all AT27 power components that require testing. In this case, the medium voltage is obtained from a source of auxiliaries of limited power. For this we use power supplies with parameters:

- 3 phases 380 V, 7 - 35 kVA

- 3 phases 480 V, 7 - 35 kVA (optional).

The power value of the auxiliary power supply depends on the rated power of the Triol AT27 and is determined by the manufacturer.

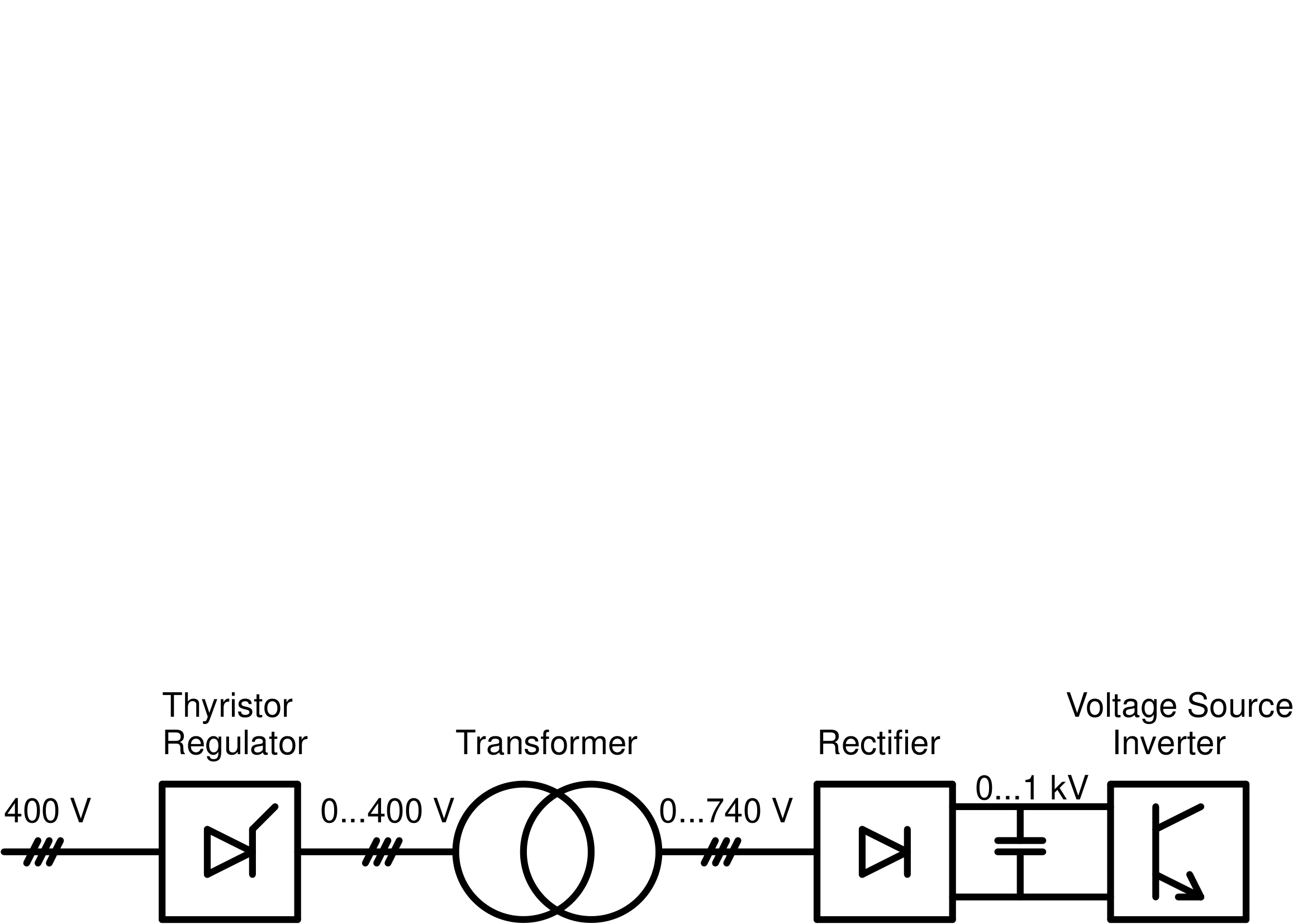

The thyristor regulator generates a medium voltage, which operates on the low-voltage winding of the power transformer.

In response to the power transformer, galvanic separation of high-voltage and low-voltage mains is ensured, which allows the creation of a medium voltage on AT27 components without being connected to the mains. It also opens up the possibility of diagnosing such AT27 components as:

- power multi-winding transformer;

- power cells (rectifier and IGBT inverter);

- medium voltage measuring circuits.

WHAT BENEFITS DOES THIS BRING TO THE USER?

The proposed solution allows the user at each start to:

- make sure that all components and systems are in good operating order before supplying medium voltage from the mains;

- make sure that all power cells and the inverter as a whole are operating at idle (without load); ,

- avoid irreversible damage to the power windings of the transformer with the development of insulation breakdown in the areas of the damaged winding;

- avoid irreversible damage to power cells during the propagation of emergency processes in them during the first start-up;

- avoid a fire in the AT27 power unit in case of any malfunctions.

The limited power of the power source doesn’t allow the sustained progressing of failures, accompanied by arc discharges, melting of insulation and current-carrying power mains, and the occurrence of fires. This function makes diagnostics safe and the VFD quickly recoverable even in case of a local fault.

Full diagnostics of the Triol AT27 before the medium voltage is supplied allows the user to save the equipment from being put into operation, saving time and money in the event of failures during commissioning, either due to the fault of any equipment, or due to personnel making mistakes during installation and commissioning.

HOW IS IT DONE?

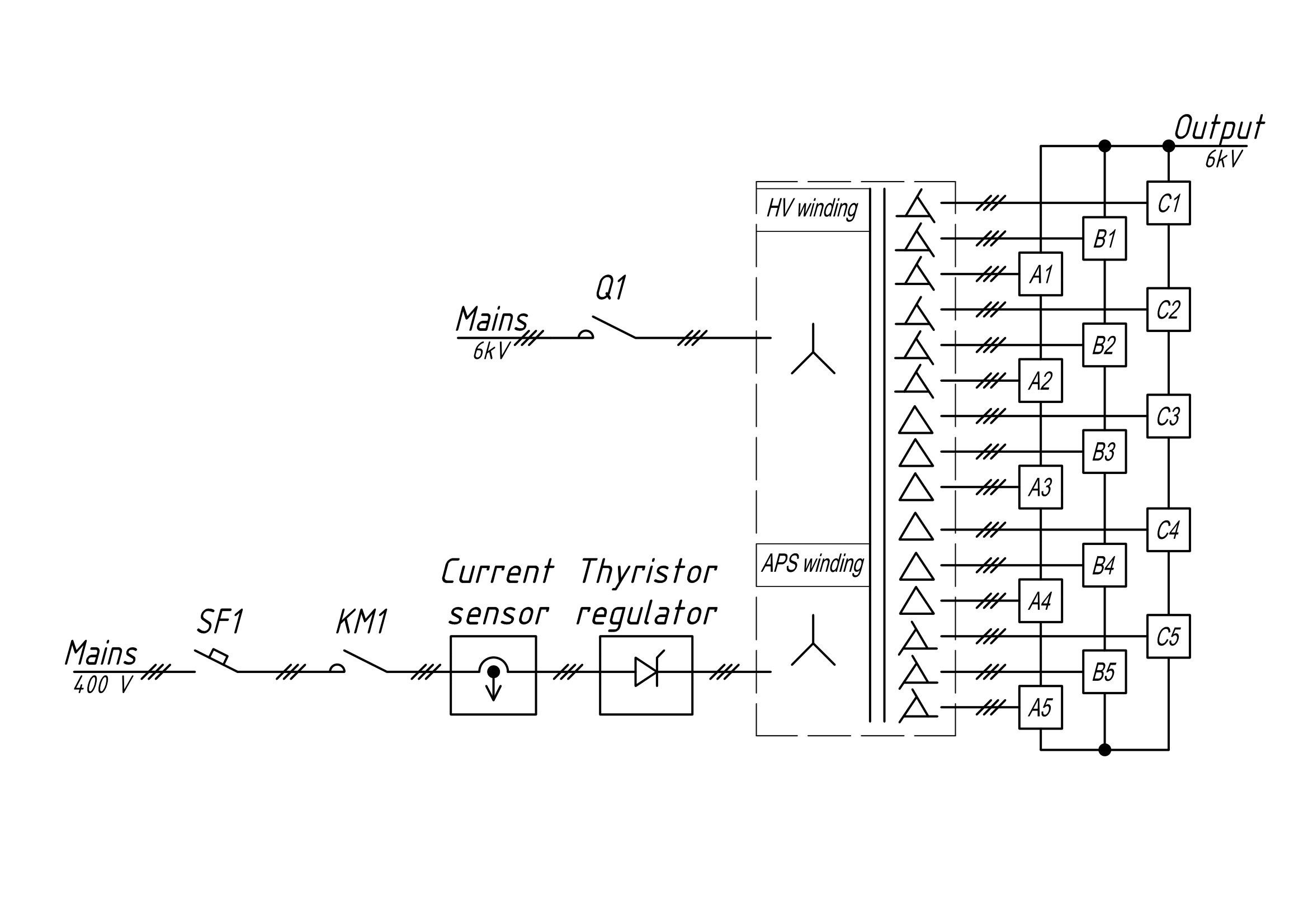

The main component responsible for the safe diagnosis of the medium voltage components of the AT27 is the power cell pre-charge system. This system is built on the basis of a thyristor regulator powered by an auxiliary voltage source protected from emergency processes by a circuit breaker.

The pre-charge system can operate both in automatic and manual mode.

Functional diagram of the power cells pre-charge system.

This system is an original, patented solution of Triol Corporation (application 2020124674 dated 07.24.2020), the essence of which is as follows: In automatic mode

- After the “Start” command is received, the KM1 contactor is switched on, supplying 0.4 kV power to the thyristor regulator, the output of which is connected to the auxiliary winding.

- On the windings of the 0.7 kV power transformer, the voltage gradually increases, which charges the DC link capacitors installed in the power cells. The thyristor regulator current sensor unit controls the capacitor charging current.

The charging time of the capacitors depends on the power of the VFD and on the set charging current, which ranges from 5 to 40 A.

In the process of pre-charging, the AT27 control system constantly monitors the state of the power cells. After reaching an operating voltage of about 1000 V on the capacitors, the KM1 contactor is switched off and the Q1 switching device – a vacuum switch or a contactor that supplies voltage to the VFD – is turned on. Furthermore, the inverter of the VFD starts with the formation of the output voltage and frequency.

In manual mode To diagnose the operability of the power cells, we offer a manual mode to set the voltage value in the AT27 power cells ("Angle test"). In this case, the user can controllably increase the voltage in the DC link of the power cells by changing the value of the thyristor firing angle . At the same time, it is possible to evaluate the status of each power cell online as the voltage increases according to the information displayed by the controller UMKA. Such functionality of the Triol AT27 allows detection of a malfunction in a power cell at reduced voltage, without leading to the development of an emergency.

Another great quality of the pre-charge system that we talked about in this article is the ability to limit the starting current of the AT27. Thanks to the pre-charged capacitors of the power cells, at the moment of connecting to the main, the starting current through the mains winding of the power transformer and through the rectifiers of the AT27 power cells is limited. This useful property not only allows the life of the VFD’s power components to be extended, but also avoids false triggering of the relay or microprocessor protection of the switchgear, followed by its shutdown.

WHAT IS THE FUNDAMENTAL DIFFERENCE BETWEEN TRIOL’S TECHNICAL SOLUTION AND ITS COMPETITORS’?

Our philosophy of building reliable and safe solutions in the field of variable frequency drives involves solving the two problems of Safety and Reliability at the same time. We have implemented more than just an inrush current limiter, which is found in the following VFDs: ABB, TMEIC, Danfoss, WEG, Hiconics. We have implemented a pre-start diagnostics system for the power section of the VFD and an inrush current limiter at the same time! This is the crucial , fundamental difference of our technical solution in comparison with the technical solutions of other manufacturers! How the AT27 protects the motor, how motor protections are implemented, and what we think about the differential protection of powerful electric motors powered by VFD, we will tell in a future publication.

Our next publication will be devoted to how to implement optimal solutions for integrating the AT27 into the enterprise infrastructure in terms of connecting to the power supply sections of the switchgear and to the customer's load.

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google