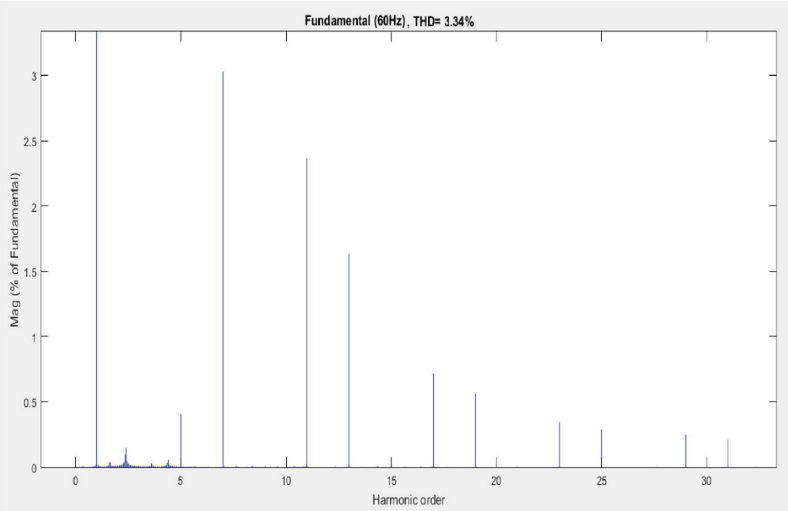

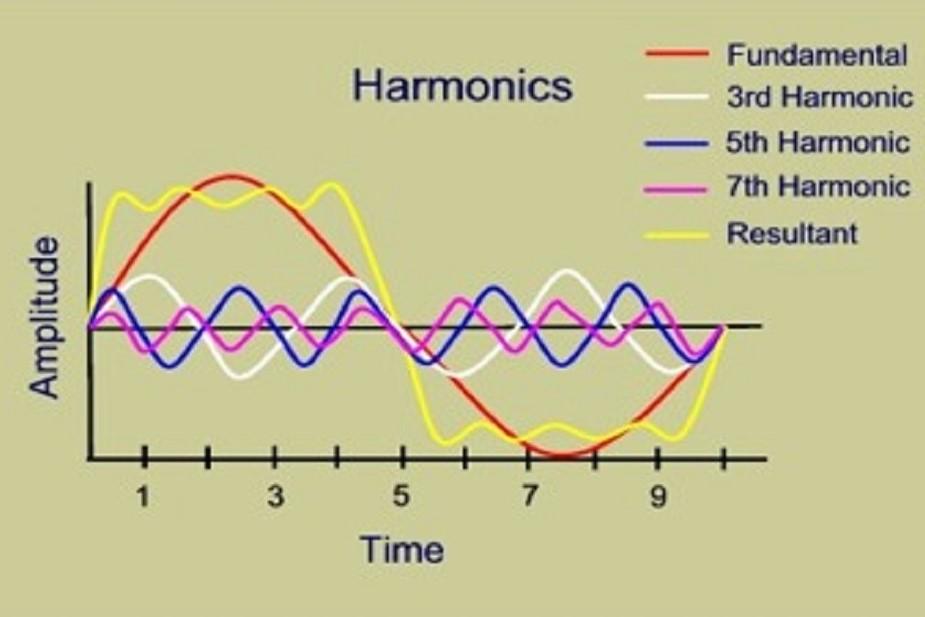

Each VFD in addition to all the advantages also has the disadvantage that it generates its own harmonic distortion of the mains current sinusoidal (THDi). A 6-pulse diode rectifier is the main contributor to the distortion. The rectifier generates a non-sinusoidal current which interacts with the mains supply and affects the mains voltage. Depending on the magnitude of the supply voltage, the effect of distortion may appear to a higher or lower degree.

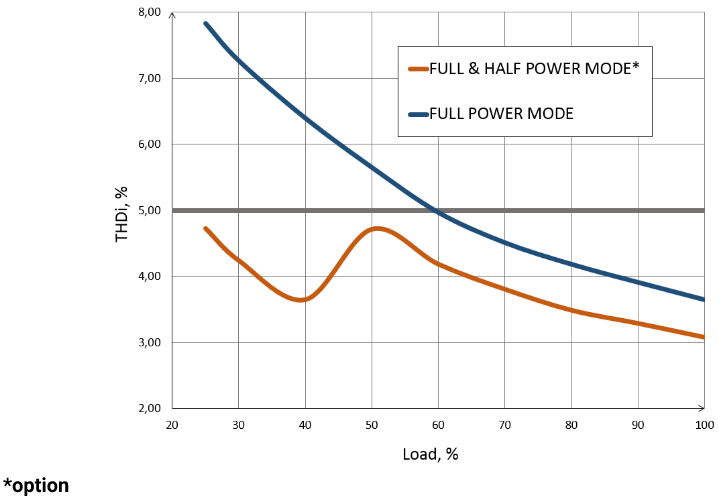

Figure 1 - Input THD level

Harmonic distortion in a three-phase AC mains can cause harmonics with unacceptable frequency components to appear instead of 50 Hz or 60 Hz. If this process is not controlled, harmonics can negatively affect the performance and functionality of generators, transformers, and other equipment. Also, due to mains voltage distortion, overloading and overheating of cable lines, generators and transformers often occur, resulting in increased power losses and reduced system efficiency.

Figure 2 - Influence of harmonics on the current sinusoid

In 1992 the IEEE 519 standard was introduced, which regulates equipment requirements in order to comply with harmonic distortion regulations. Compliance with IEEE 519 will avoid a financial loss to the end-user:

- due to sanctions from power supply companies (related to degradation of mains current due to harmonics), if such requirements are imposed by the power supplier;

- unstable system operation and accidental equipment shutdowns often lead to process failures. Triol Corporation offers both complete solutions, equipment with built-in harmonic control elements to comply with IEEE 519, and solutions that complement existing equipment in all areas, such as: oil production, drilling, industrial equipment (conveyors, ventilation and cooling systems)

Triol's harmonic solutions.

1. Passive filter built into the frequency drive.

Triol Corporation produces three lines of variable frequency drives for oil production:

-

VSD AK06 SR and LH lines for ESP operation

-

VFD AT24 line RT for sucker-rod and screw pumps

The equipment of these lines allows to save THDi deviation not more than 5% when loaded up from 25% to 100% by input active current.

The CP line is designed in a NEMA4 or NEMA4X-rated enclosure, when it combined with the built-in filter, makes this VSD line perfect for oil platforms, as it saves space and time for installation.

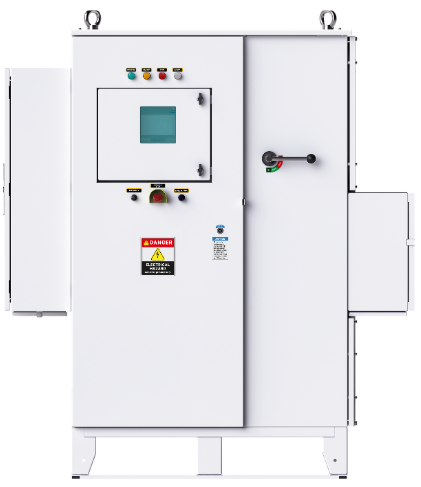

Figure 3 - VSD line SR general view

The LH line is designed in a NEMA3R-rated enclosure, and is the more suitable solution for Onshore wells.

Figure 4 - VSD line LH general view

The RT line is designed in a NEMA3R-rated enclosure and is the solution for wells operated with SRP or EVN with capacities from 15 kW to 200 kW.

Figure 5 - VSD line RT general view

2. Passive filter in a separate enclosure.

Since the VSD lifetime is more than 5 years and the IEEE 519 standard was updated in 2014, this means that some of the existing VFD fleet does not meet the requirements of this standard, to solve this problem Triol Corporation offers a freestanding passive THF filter. The filter provides a THDi less than 5% when loaded with 25% to 100% on input active current.

Figure 6 - THDi readings

The filter is designed in a NEMA3R enclosure and is suitable for operation in the temperature range from -20 to +45 °C, which can be optionally extended from -40 to +55 °C. It is possible to use the filter with 6 and 12 pulse drives. The filter is equipped with:

- mains analyzer;

- Overload and short circuit protection;

- Wi-Fi module;

- Contactor for disconnecting capacitors when VFD is stopped.

Figure 7 - Passive THF filter general view

Figure 8 - Mains Analyzer Example

You can read more about the THF filter in the catalog at https://triolcorp.us/documents

3. Phase-shift transformer.

For operating conditions using a generator as a power source, and for operations with supply frequency fluctuations from 45 to 65 Hz, Triol Corporation has developed the VSD line PS, which uses an active phase-shifting transformer in its design.

Figure 9 - The device schematic diagram

The VSD line PS provides a THDi up to 5% in the 25% to 100% active input current load range. This line VSD is designed in a NAMA4 or NEMA4X enclosure and has an operating temperature range of -20 to +60 °C.

Figure 10 - VSD line PS general view

VSDs line PS are an excellent solution for oil platforms or remote locations from the main power lines, and the field is supplied with electricity by generators.

4. Active rectifier.

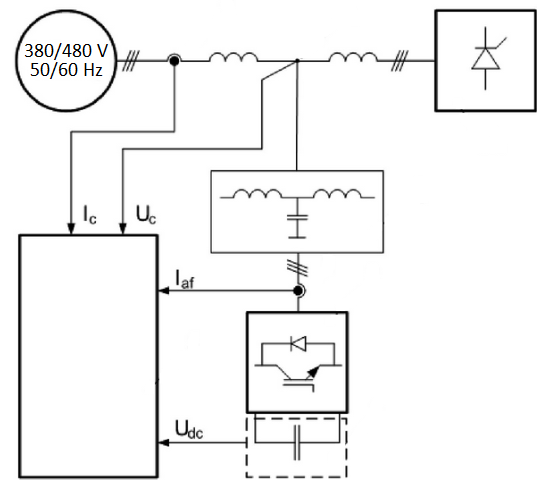

Figure 11 - VFD scheme with an active rectifier

The active voltage rectifier is used in applications where low current harmonics are required. The advanced element base, the latest control principle as well as a high-quality filter ensure a THDi of less than 4 %.

An active voltage rectifier operates at a high switching frequency and delivers a sinusoidal current to the mains. Therefore, it is a device that provides energy recovery and serves as an alternative for the application of active and passive filters. The THDi of the VFD becomes less than 4% when an active voltage rectifier is used.

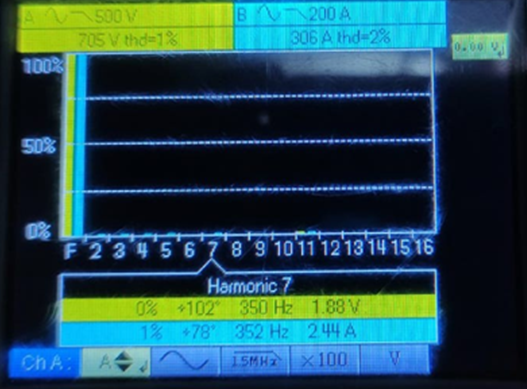

Figure 12 - THD value during frequency drive AT24 line MP test

The frequency drive AT24 line MP with an active rectifier operates at THDi=2%.

5. Multi-pulse equipment.

One of the simplest ways to handle harmonics is to use 12, 18, 24 pulse VSDs. THDi at full load for drives:

12 – 8 %...12 %

18 – 4 %...6 %

24 – 4 %...5 %

Figure 13 - Current THD at different VSD pulses

Triol Corporation offers UD and SD lines, which has a range of all capacities with pulses of 12, 18, 24.

Figure 14 - VSD line UD general view

VSD line UD with 18 and 24 pulses is an affordable solution for providing IEEE 519 standard, in case of using a phase-shifting step-down transformer. VFD AT24 line SD with 12 pulses allows to reduce THD up to 8%, when operating as general industrial equipment and drilling rigs.

Figure 15 - VFD line SD general view

Triol is the best solution to protect your mains and your finances.

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google