Key benefits of using submersible telemetry systems Triol TM01-20 and TM01-25

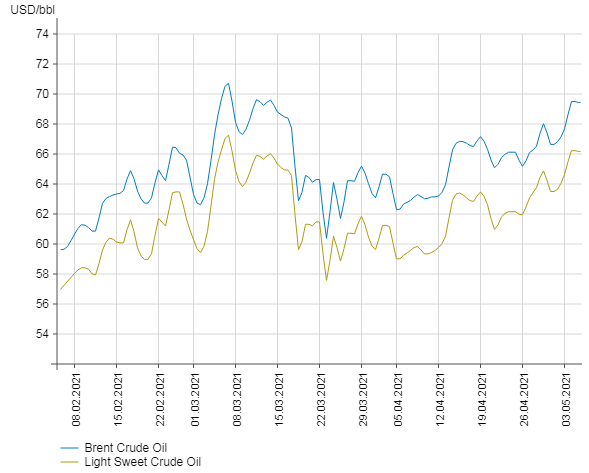

In the context of volatile oil prices and the complexities associated with the pandemic, the requirements for submersible equipment have grown and telemetry systems are no exception.

Triol’s specialists have analyzed the market and identified new challenges that the current situation has created for the telemetry system.

New challenges for telemetry:

- High-accuracy measurement of well and submersible equipment, which will maximize well flow rate;

- Increased time between overhauls;

- Reliability;

- Ease of installation and HMI;

- Versatility.

ТМ01-20 and ТМ01-25 are two new telemetry models that solve challenging technological problems. Benefits that you and your customer will receive:

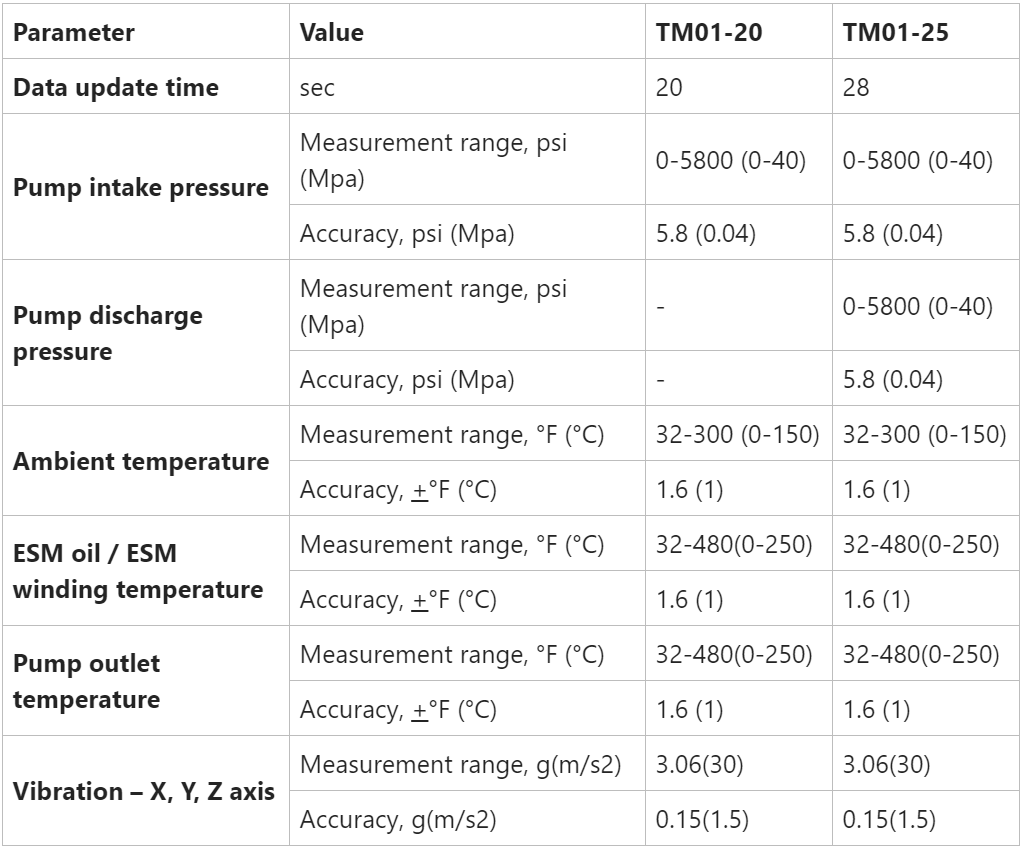

1.The accuracy of temperature measurement is ± 1.8°F (± 1°C) and pressures of 5.8 psi (0.1 atm), while the data update rate for TM01-20 is 20s, and for TM01-25 is 28s.

Due to the accuracy of measurements, telemetry is able to maintain a low dynamic level and increase the flow from the well. TM01-20 and TM01-25 are capable of operating at ambient temperatures of up to 150°C.

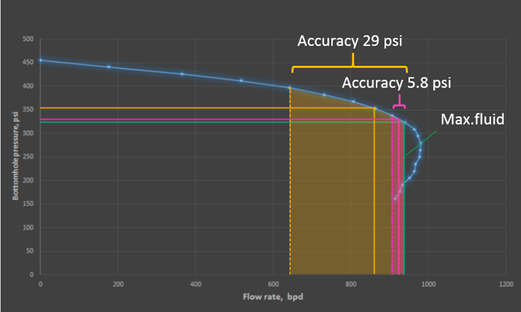

Let's consider the well indicator diagram:

Flow rate vs. bottomhole pressure diagram

The graph shows that with a pressure measurement error of 29 psi, the unit operates in the orange zone, and the average production rate is 861 bpd. Reducing the pressure measurement error at the pump intake to 5.8 psi will allow the ESP to operate in the pink zone, which will increase production by 7.3% (924 bpd). TM01-20 and TM01-25 Submersible telemetry parameters:

2. Increase in pump resource and overhaul period due to the use of TM01-25 telemetry.

2.1 Increasing the pump resource by controlling the temperature at the pump outlet.

By monitoring the temperature at the pump outlet, it is possible to track the beginning of wear on the pump bearings, which will allow users to:

- predict the replacement of equipment and reduce the downtime of the well;

- correct the operation of submersible equipment to increase the overhaul period.

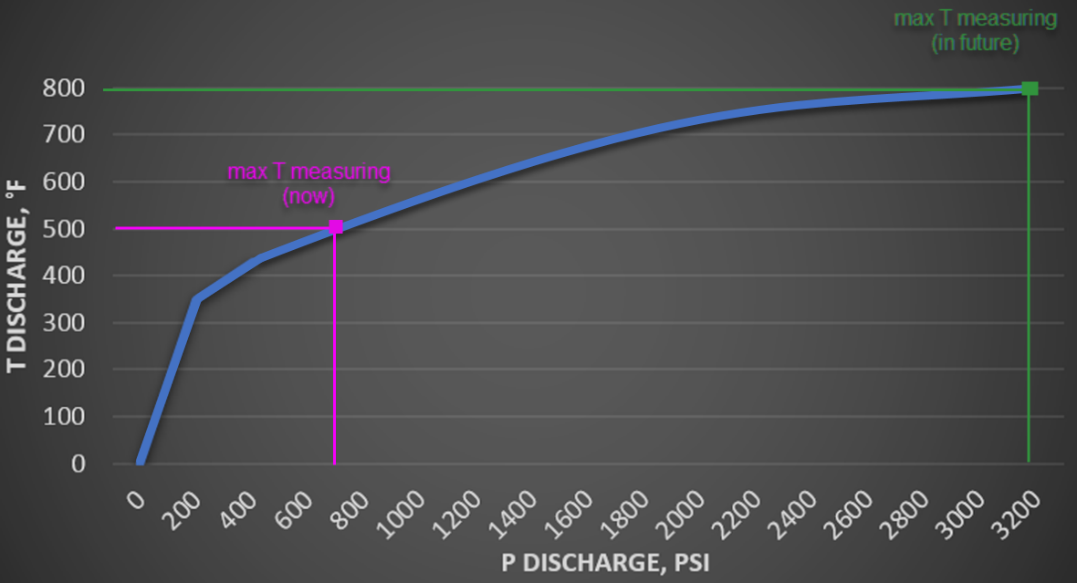

2.2 Increase in the overhaul period during the operation of centrifugal pumps in a fund complicated by salts. It's no secret that the process of salt deposition is maximal when the formation water boils.

Consider the graph:

Data on temperature and pressure will avoid the boiling of formation water and, as a result, increase the turnaround time and reduce the cost of tripping and lifting operations.

Let's consider an example of calculations:

The average cost of launching and lifting the rig is $8,000 at an average descent depth of 8,200 ft (2,500 m). Well downtime can be up to 2 days, with an average production of 314 bpd (50 m3/day) – this is 628 bbl (100 m3) of unproduced oil. When using TM with control of T (outlet temperature) and P (outlet pressure), it is possible to reduce the maintenance costs of installations that are used in wells with a salt fund and a simple well by $213,000 to $400,000 per year (the calculation was carried out at an oil price of 25 dollars / barrel of raw oil).

3.Reliability, which is guaranteed through the use of high-quality components from top manufacturers: ANALOG DEVICES, Texas Instruments, ATMEL, and AzSensCo.

Each telemetry also undergoes acceptance tests, during which the product operates at maximum operating parameters for 10 days.

Test flasks to simulate well conditions The surface part of the stand to monitor operation

4.Easy to install and work with telemetry:

4.1 Installation time takes no more than 15 minutes;

4.2 For customer convenience, we’ve developed video instructions on the installation and connection of telemetry:

You can view the TM01-20 installation process: https://www.youtube.com/watch?v=RsZgvtrpCIw

You can view the TM01-25 installation process here: https://www.youtube.com/watch?v=y2mUABDjB0g

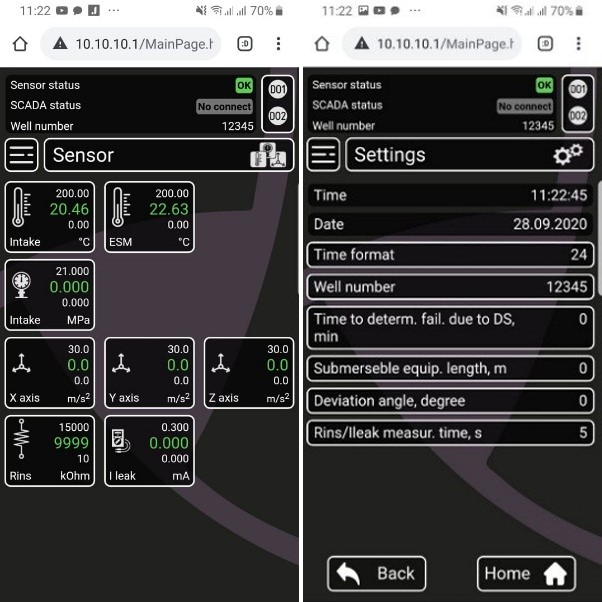

4.3 The conceptually new surface units of the telemetry system have been developed for user convenience. Their main task is to improve the convenience of data processing and access to this data without the use of additional equipment. Features of Triol surface equipment:

-

View well and submersible equipment parameters on a mobile device, with no need to install additional applications;

-

Configure the protections of connected equipment via discrete outputs on a mobile device;

- View graphs of changes in telemetry parameters without special software or a laptop. Graphs Engine and ambient temperature;

- Engine and ambient temperature;

- Pressure at pump inlet and outlet;

- Motor vibration;

- Leakage current.

The Wi-Fi network of each surface part of TM01 is protected by password from outside connections.

Let's consider two design versions: Triol Surface Card The Triol Surface Card is rated IP20 and is used inside control stations or in other dust- and waterproof environments. The main task is to receive data from the submersible unit and transmit it to the control system controller or SCADA.

Triol Surface Panel The Triol Surface panel is NEMA 4X-rated and can be installed outside the control station, including on offshore platforms. If the customer's frequency drive has limited functionality or no display for control, you can use this device to set submersible equipment protections for parameters such as:

- pump inlet and outlet pressures;

- motor winding and ambient temperature;

- vibrations;

- leakage current.

It is also possible to view data values and display graphs thanks to the helpful 5-inch display.

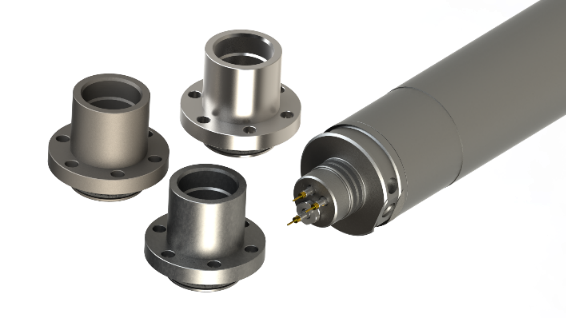

5.Versatility is achieved by universal connection to any type of motor and operation with RDT and J type temperature sensors.

5.1 The external diameter of the telemetry is 3.75 inches (96 mm). And the flange mounting system allows to connect the TM without using additional adapters and as a consequence without increasing the sealing locations as one of the risks of failure of the submersible motor.

5.2 The TM01-20 and TM01-25 provide for connection of temperature sensors type RDT or J. The temperature sensor comes with the telemetry, but the customer can also use their own temperature sensors.

Download the catalog "Triol TM01 Telemetry Systems" and learn more about this product!

We are confident that through this cooperation, you will solve all your most complex problems in the most profitable way for you!

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google