New production facilities in Poland are equipped with modern painting equipment!

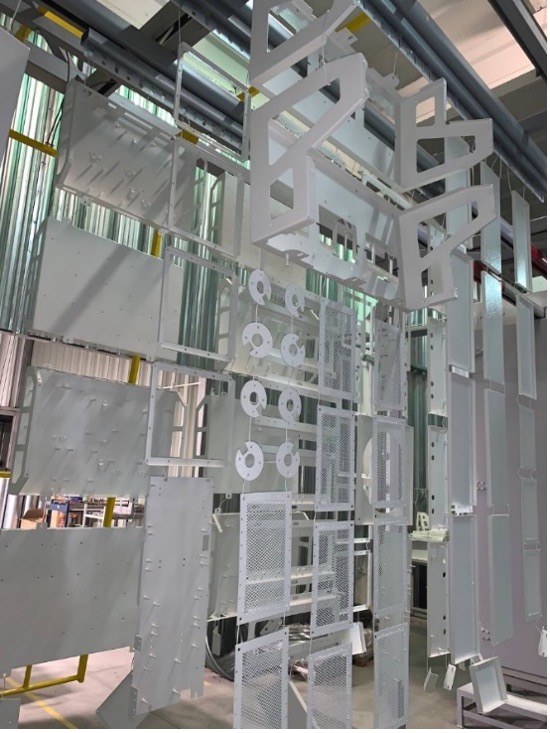

The new facilities are supplied with a new complex for powder coating of parts.

The new complex includes two coating units. The first is for semi-finished products and small items. The second is for painting large products with dimensions up to 6 meters in length.

Our equipment is painted using the powder coating method. This method makes it possible to obtain a high-quality and durable coating, especially for different climatic conditions, from tropical to arctic, which extends the geography of Triol products.

Triol products go through several stages of painting, including layers with zinc-containing paint, which allows one to work in the most difficult conditions, including in sandy and salt spray environments. The product also maintains a degree of protection of the enclosure NEMA 4.

The coating is applied in two steps:

- A special primer containing zinc is applied.

- The final layer of powder coating is decorative, which provides color and the desired thickness of the coating.

This method of painting provides good adhesion and durability of the coating.

This method of painting provides good adhesion and durability of the coating.

https://drive.google.com/file/d/11ZyYWVHdwyJd8LmmCznEZdIqMU1tOggE/view?usp=share_link

After applying two coats of paint, the unit is maintained at a temperature of 180 degrees Celsius.

https://drive.google.com/file/d/10iT8PwicMHJO5E1ManH5F1S3nFGG864z/view?usp=share_link

This coating technology and quality of materials has a successful experience with customers in many countries around the world with different types of climates.

The painting is done with a professional tool that allows us to control the thickness of the coating, even in the most difficult parts of our construction, where conventional types of equipment are not so effective.

https://drive.google.com/file/d/1yrLVRCGq3QYomRzzniN_2kmBnFOJe5C9/view?usp=share_link

The NORDSON Encore LT powder coating gun allows us to apply powder coating at a low powder-flow rate, which leads to less wear and tear in the future and thus increases the lifetime of the finished product.

Also, the paint booth system is a closed circuit. The air inside the chamber circulates and there are no paint emissions into other rooms or the atmosphere. This is ensured by a special filter system.

Triol Corporation delivers the best solutions to its customers.

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google