The variable frequency drives (henceforth VFD) market expands with time. New models of VFD appear and old technological solutions are modernized, but Triol VFD still remains the leader with the smallest dimensions. In our previous article,14 Reasons why Triol AT27 VFD is arguably the best Medium Voltage Drive in the World, we compared the dimensions of Triol VFDs with similar drives from other manufacturers. Today we are analyzing how the situation with the dimensions of the various manufacturers has changed over the last year and conducting a comparative analysis of their dimensions with the Triol AT27 VFD.

Medium-voltage frequency drives can be built according to different topologies:

- multilevel voltage inverter,

- current inverter,

- three- and five-level voltage inverter with transformer and transformerless circuit,

- two-transformer inverter circuit, etc.

Each of the variants has its place, but we are in favor of VFD built on the topology of a multilevel voltage inverter. Therefore, we will compare similar products among the world’s manufacturers of medium voltage frequency drives that are built on a topology of multilevel voltage inverters.

When designing and implementing a project, every 10 cm makes a difference and can affect cost and timing. Our customers are often faced with the fact that the required equipment does not fit into the available space. This can lead to the rejection of the project as a whole. Or the project can be delayed and costly if new buildings need to be erected to locate the converter equipment.

The use of the AT27 VFD ED line will save not just a few tens of centimeters but an average of 25-30% of the space occupied by the VFD. And since 2022, this figure is even higher! This means new investment opportunities and open doors to more projects. Read more about this below.

AT27 ED line 6kV and 6.6kV

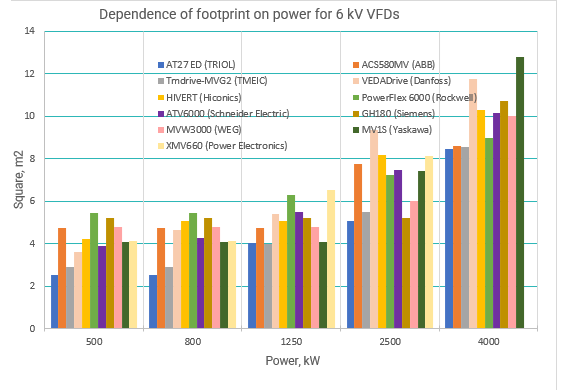

The dimensions of Triol VFD for 6kV and 6.6kV are the same. Most competitors use the same dimensions, although not all. For comparison, we took the data of competitive models either for 6/6.6kV or for 6kV only, if the manufacturer does not have models for 6.6kV. Below we have presented the data in the form of a related diagram, which allows a quick comparison of the footprint of the most popular VFD models in this class.

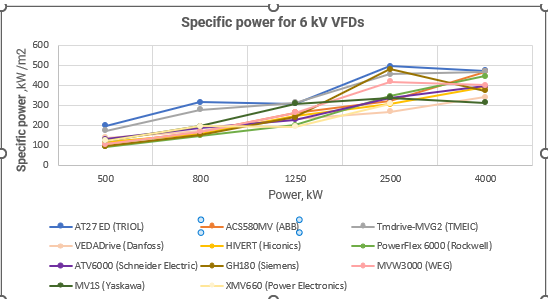

If we present the same data in the form of a graph comparing specific values, it looks like this:

As can be seen from the diagram, the total footprint of the AT27 6kV and 6.6kV VFDs is already best-in-class, especially for VFDs with power rated up to and including 800 kW. For the 2022 AT27 VFD in the 2022 year, this rate increased to 13% for power up to and including 800 kW. However, the space required to place the product is not everything.

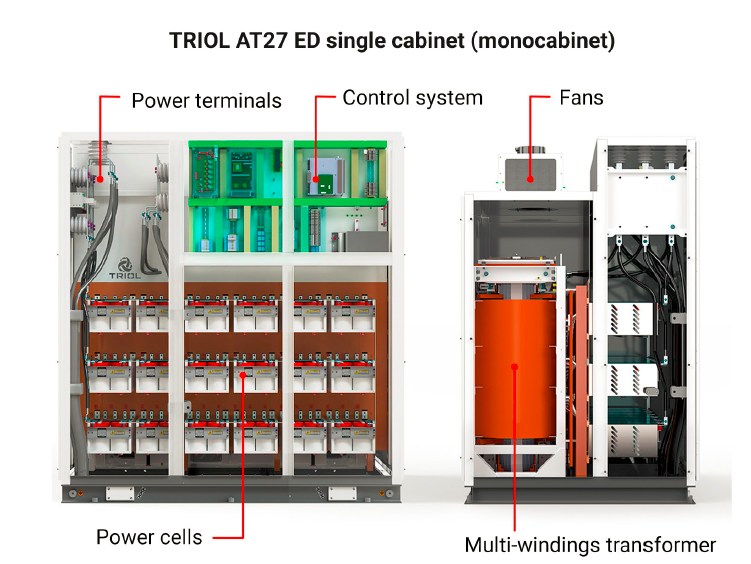

First, a minimum square footage/power ratio can be achieved in a number of ways. For example, many manufacturers of medium voltage VFDs minimize the size but “sacrifice” the convenience of one-way service. This is a significant disadvantage. All products of the AT27 ED line are designed in the smallest possible dimensions, taking into account the preservation of one-way service. The smart, compact design makes it possible to replace or repair any drive unit from the front side.

Second, the VFD has a cooling system, which also affects both the size of the VFD and the size of the room. VFDs of such power “throw” into the environment dozens of kilowatts of heat, which must be removed from the frequency drive or from the room to avoid overheating. In the AT27, the cooling system is designed to allow the VFD to be placed directly “under the wall,” without the additional corridor, which is often necessary for both air exchange and safe servicing. This is an additional benefit because such corridors “eat up” at least 1 m along the entire VFD.

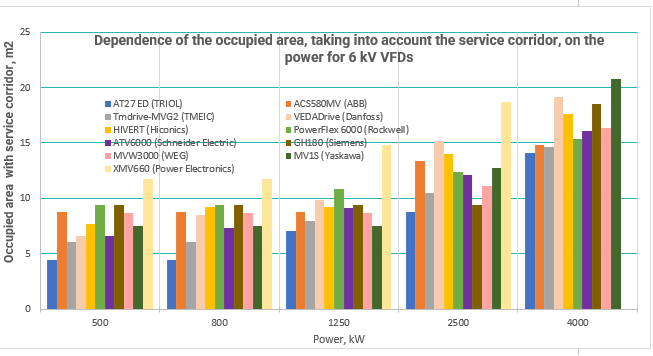

Taking this into account, the final picture with the dimensions of the drives looks like this:

As you can see, the difference became even more significant and reached an average of 36% for the series as a whole.

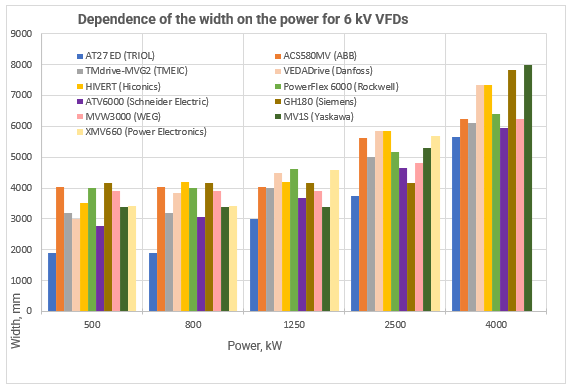

In addition, we have minimized the width of the VFDs because this is the criterion by which medium-voltage VFDs that are used in existing electrical rooms most often do not align with the given requirements.

As you notice, the Triol AT27 compares favorably with other VFDs.

AT27 ED line 10 kV

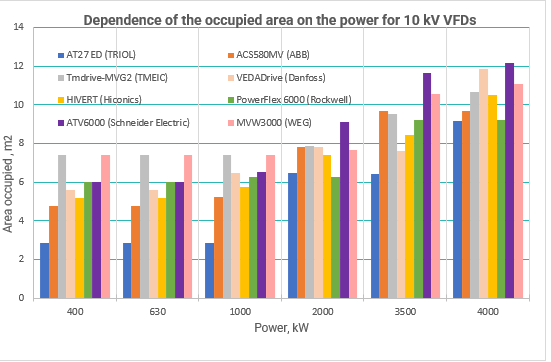

Let’s go further and compare VFDs with a rated output voltage of 10 kV. The dependence of the area occupied by 10 kV VFDs on their power will look like this:

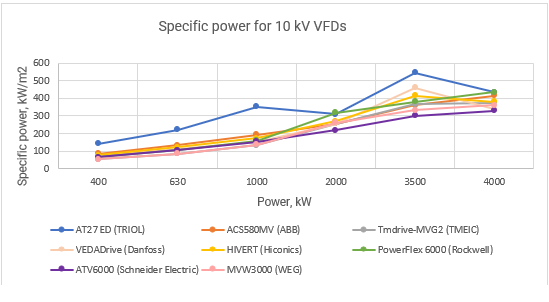

The same data in the form of a graph of the specific ratios is as follows:

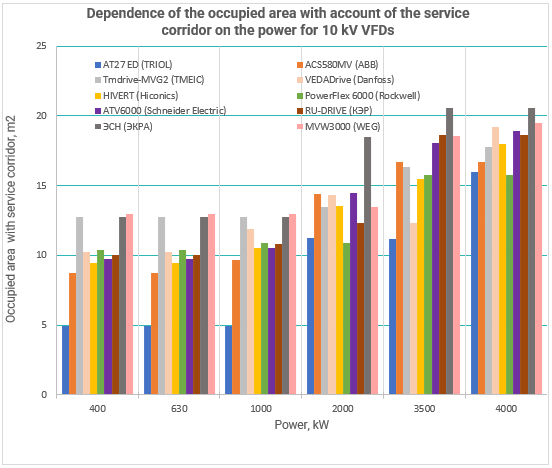

Once again, let’s compare the areas occupied, including service corridors, now for 10 kV series models:

As can be seen from the diagram, AT27 VFDs occupy the minimum area. Taking into account the service corridor, the difference is especially large for VFDs up to 1000 kW, where this difference reaches twice the value. This makes Triol’s variable frequency drives the most advantageous for use in conditions in which there is a lack of free space.

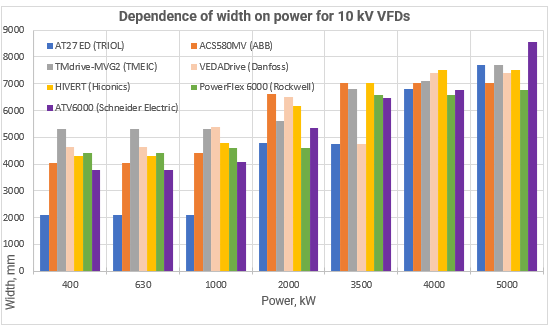

In addition, let’s estimate the width of VFD’s 10 kV ED line:

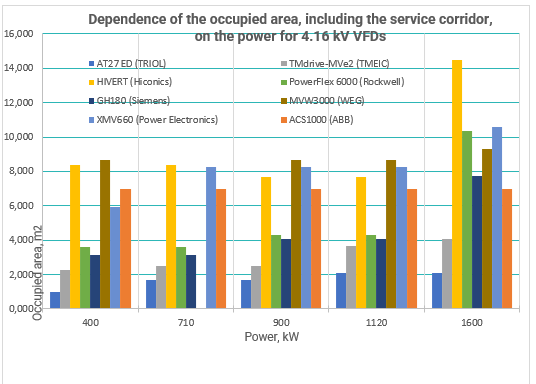

AT27 VFD ED line 4.16 kV

Most interesting for markets in the USA, Latin America and Saudi Arabia are the VFDs with an operating voltage of 4.16 kV.

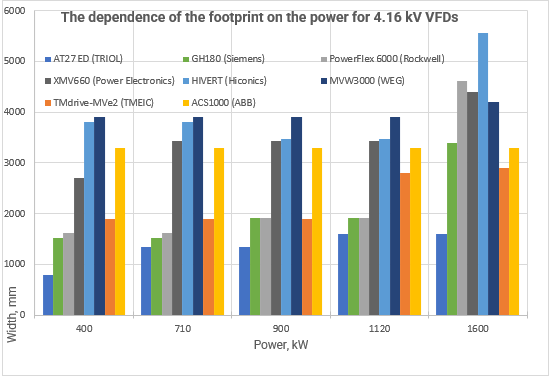

Triol Corporation has developed compact solutions for this voltage rating. The dependence of the footprint of 4.16 kV VFDs on their power will look like this:

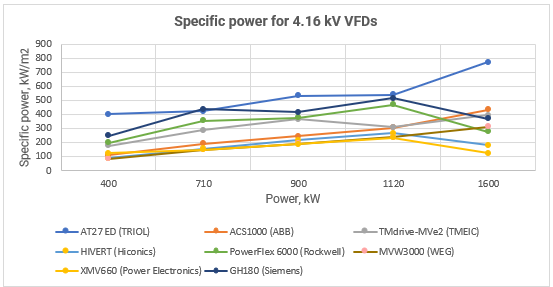

If we present the same data in the form of a graph comparing specific values, it looks like this:

Once again, let’s compare the areas occupied, including service corridors, now for the 4.16 kV series models:

A special feature of Triol VFDs with an operating voltage of 4.16 kV is their compact dimensions. The Triol VFD is the only one that can be placed on a 1 m2 floor space, with a rated power of up to 500 kW. On average, the footprint of Triol drives is 56% smaller than competitors have, which allows you to use the equipment on sites where tenths of a square meter of space play a big role. For example, on oil extraction platforms, one square meter of space for equipment can cost hundreds of thousands of dollars.

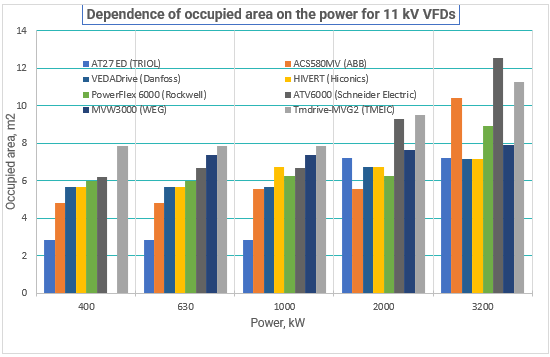

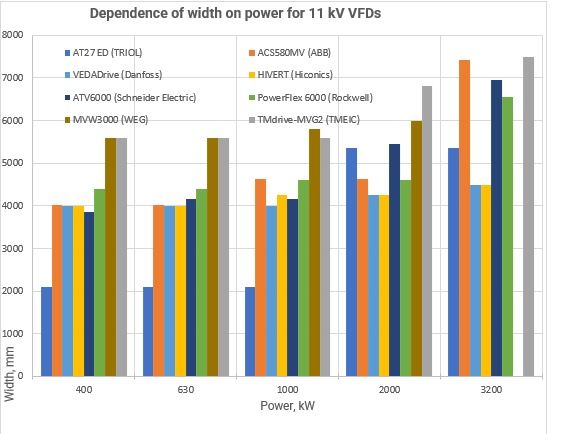

AT27 VFD ED line 11 kV

Next, we will compare VFDs with a rated output voltage of 11 kV. The dependence of the area occupied by 11 kV VFDs on their power will look like this:

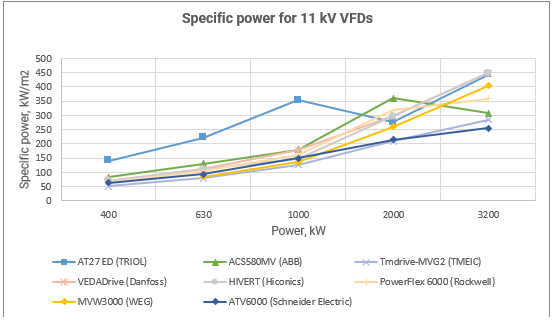

The same data in the form of graphs of specific ratios:

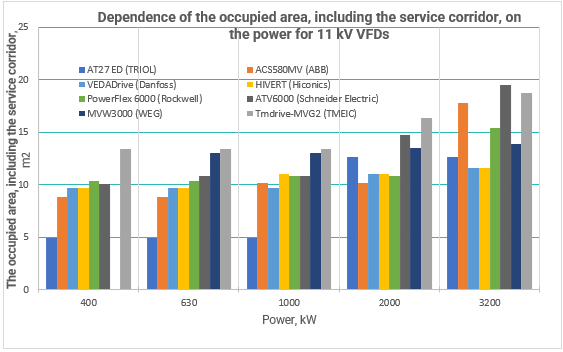

Once again, let’s compare the occupied areas, including service corridors, now for the 11 kV series models:

As can be seen from the graphs above, AT27 VFDs with an operating voltage of 11 kV have a significant advantage over competitors in the occupied area by 29-45% for VFDs up to 1000 kW included. As for VFDs with power over 3000 kW, the AT27 has comparable values with the world’s well-known manufacturers. As can be seen from the diagram, AT27 VFDs occupy the minimum area. Taking into account the service corridor, the difference is especially large for frequency drives up to 1000 kW, where this difference reaches twice the value. This makes Triol’s VFDs the most advantageous for use in conditions in which there is a lack of free space.

In addition, let’s estimate the width of the VFD 11 kV ED line. They look like this:

The parameters of the 11kV AT27 width have the same tendency as those for the occupied areas.

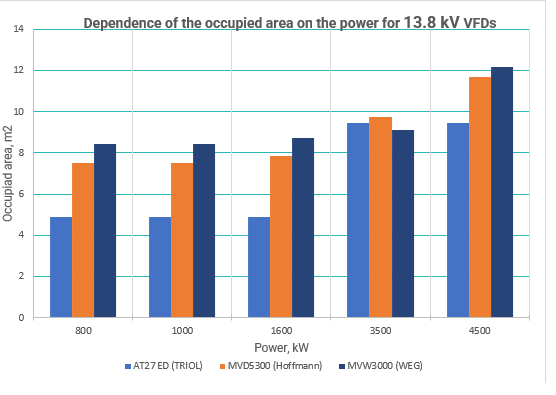

AT27 VFD ED line 13,8 kW

Before analyzing the dimensions of the AT27 in comparison with competitors, it should be noted that the market offers a limited number of commercially available VFDs for operating voltage 13.8 kV. In this respect, the Triol Corporation is one of the few companies that offer commercially available VFDs with an operating voltage of 13.8 kV.

Next, let’s analyze and compare VFDs with a rated output voltage of 13.8 kV. The dependence of the area occupied by 13.8 kV VFDs on their power will look like this:

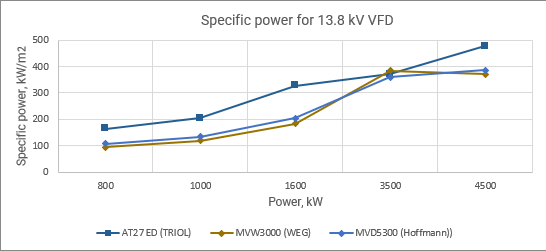

The same data in the form of graphs of specific ratios:

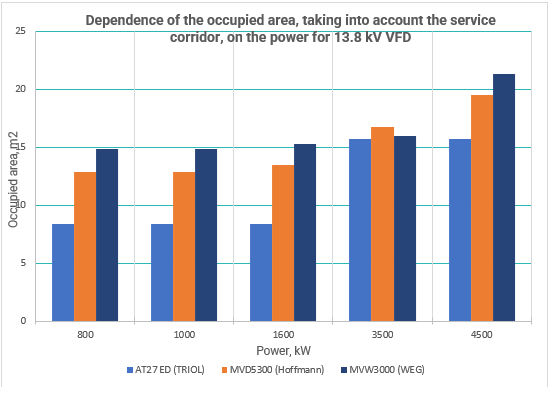

Once again, let’s compare areas, including service corridors, now for 13.8 kV series models:

As can be seen from the above graphs, AT27 VFDs with an operating voltage of 13.8 kV have a significant advantage over competitors in terms of areas occupied. On average, the whole power range is 28%.

VFD AT27 ED line in comparison with competitors - the results

To summarize the research done, the following conclusions can be made:

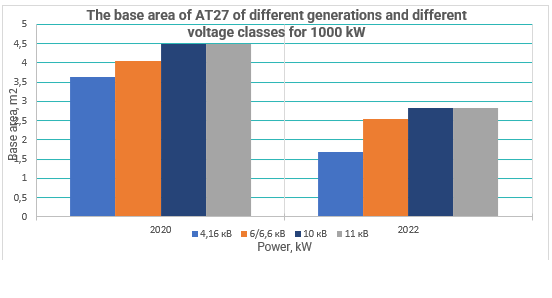

As can be seen from the above diagram, the 1000 kW of AT27 in the 2022 generation takes on average 41% less area compared to VFDs in the 2020 generation. This improvement has become possible due to the innovative solutions used in the AT27 generation 2022.

Let’s also take a look at what advantages the AT27 generation 2022 has over other manufacturers’ VFDs.

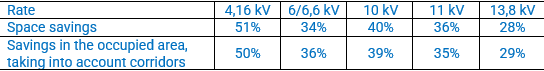

Table 1- The average area savings of the AT27 VFD compared to competitors:

The data from the table shows that the average space-saving values of the AT27 series VFDs are 28-51%, depending on the voltage class. Such savings allow end-users to reduce the cost of construction work and building materials. In some cases, this allows you to avoid any construction work at all. This is especially critical for offshore platforms, where one square meter of space for equipment costs hundreds of thousands of dollars. It is also worth noting that the AT27 VFDs are leaders in such a parameter as width. It allows you to install more VFDs in one line compared with competitors, and in some cases, only the AT27 can be placed in an existing electrical room, which saves the end-user in need for capital construction costs.

Triol Corporation strives to create equipment that is superior to the competition in terms of the main consumer indicators, which makes it attractive for use in all industries and utilities without exception. Therefore, working with Triol is profitable, convenient and comfortable!

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google