Increasing the reliability of multi-level cascade variable frequency drives is one of the biggest challenges for all manufacturers of this class of equipment.

In the history of the multi-level topology, the VFD market has long exceeded 100,000 units worldwide. It is one of the most popular medium voltage frequency drive topologies, favored by users around the world in no small part because of its relatively high reliability and long life. The use of multi-level frequency drives not only pays for the investment, but also generates real returns, in some cases paying back the investment many times over. Profit is the main marker that motivates customers to buy multi-level frequency drives.

In this article, we will look at one of the tools that led to a significant increase in the reliability of the Triol AT27 multi-level cascade variable frequency drive, leading to increased end-user profits. Paradoxically, according to the failure statistics of frequency drives, the air-forced cooling fans are the most unreliable elements. In the early 2000s, to reduce production costs, a number of manufacturers began to use inexpensive exhaust fans en masse , but by 2005 they had abandoned this idea almost completely, not only for export, but also for internal orders. This was caused by massive frequency drive faults due to air-forced cooling system exhaust fans. The problem of mass faults was solved by installing uncontrolled centrifugal fans from reputable manufacturers with a minimum MTBF of 30,000 hours. This has increased the overhaul interval of the frequency drives to 4-5 years.

How does Triol do it?

Triol Corporation has taken a quality step forward in all AT27 drive lines (ED, DD, MV and RX):

- In the production of VFD, we only use controllable fans with integrated frequency drives from well-known and proven manufacturers, which allow the fan capacity to be adjusted to the actual demand;

- For high-reliability, fail-safe solutions that require a frequency drive MTBF of at least 100,000 hours (11 years), we install reserve fans that can redistribute the load amongst themselves during normal operation and, in emergency mode, provide the required cooling operation without affecting the frequency drive;

- In order to replace a faulty fan in hot mode without stopping the frequency drive, we have provided for the installation of gravity dampers in the enclosure of the Triol AT27 frequency drive.

This solution increases the reliability of the equipment, making frequency drives manufactured by Triol essentially "indestructible". Not only is the time between overhauls increased, but a failed fan can also be repaired without the frequency drive being switched off and without reducing its performance! This ensures smooth operation and continuity of the process cycle.

There is another pleasant bonus for users of Triol AT27 frequency drives. The fact is that our frequency drive knows when the fans need to be replaced and warns you well in advance if maintenance service is required! For you, a cooling fan failure will never be unpleasant news, much less the cause of an emergency stop of your process equipment!

Let us take a look at how the AT27’s air-cooling system with the option of reserving exhaust fans works.

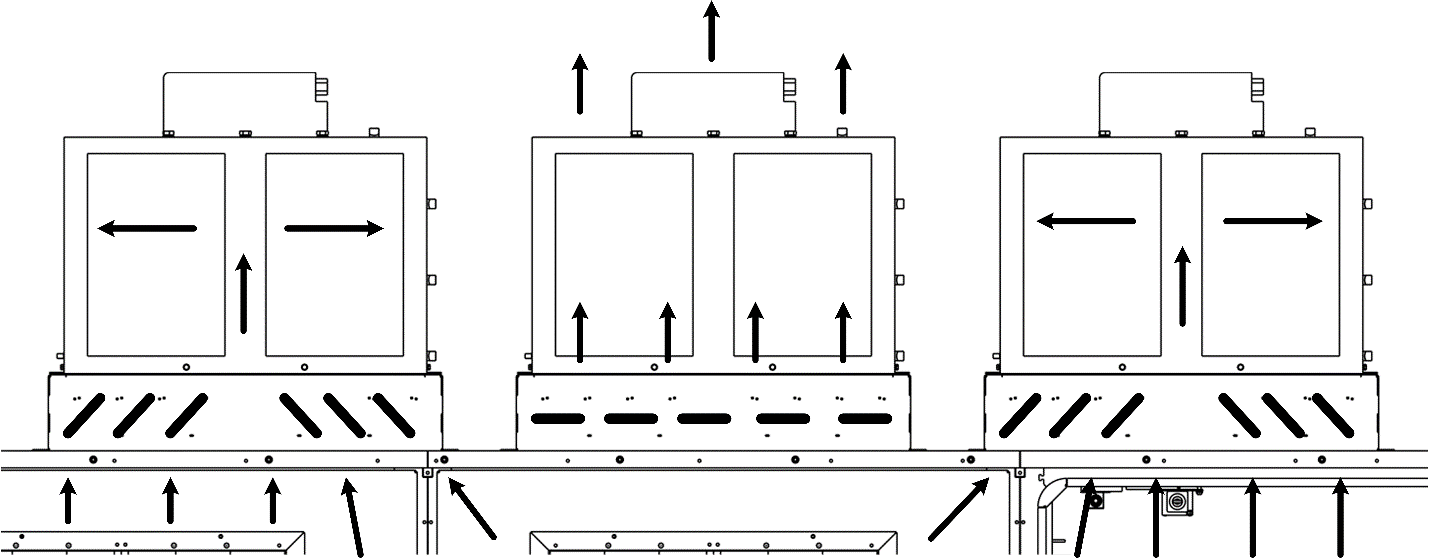

In case of reservation of ventilation of the AT27 VFD, an additional fan can be installed. All fans, including the reserve fan, are operating at the same time. The load is divided equally among all fans, and as there are more fans, they operate in light mode, which has a beneficial effect on their service life. All fans are supplied with gravity dampers so that the ventilation system can maintain its nominal operating conditions if one of the fans fails. During normal operation of the exhaust fans, a pressure differential is created on the freely rotating blades of the gravity damper, which lifts the blades and opens the duct section for heated air to be discharged from the AT27 VFD to the outside. If one of the fans fails, a reverse pressure difference is created on the damper blades due to the vacuum inside the cabinet created by the operating fans and the atmospheric pressure outside the cabinet. This pressure difference, and gravity, causes the damper blades to lower, closing off the air duct cross section and preventing other fans from 'sucking in' air from outside the cabinet and reducing the efficiency of the ventilation system as a whole.

Principle of operation of the Triol AT27 frequency drive gravity damper

How do competitors do it?

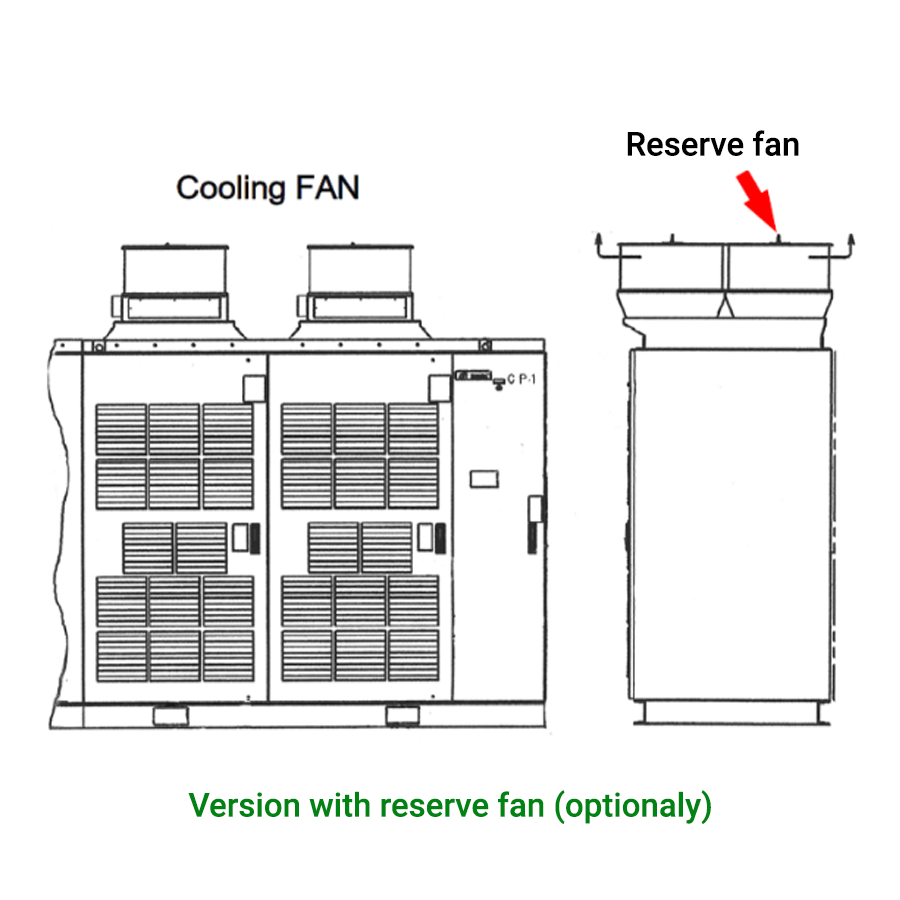

Increasing the reliability of frequency converters by reserving air-forced cooling system fans is being addressed by many companies, including market leaders. An example of a reserve fan installation is shown in the illustration below:

However, the reservation principle used by competitors is different and does not provide the benefits that can be achieved by using Triol AT27 VFDs. The essence of the reservation algorithm is quite simple:

However, the reservation principle used by competitors is different and does not provide the benefits that can be achieved by using Triol AT27 VFDs. The essence of the reservation algorithm is quite simple:

- The air-forced cooling system fans are located on the roof, on the gravity damper;

- If the main fan fails, the frequency drive is informed of the failure and disconnects it from the auxiliary power supply;

- After disconnection from the auxiliary power supply, the reserve fan is switched on;

- If necessary, a defective fan can be replaced in hot mode without stopping the frequency drive.

While short-term ventilation faults can hardly claim to be a noticeable disadvantage compared to Triol solutions, running the standby fan at full capacity has a major impact on its service life, primarily bearing wear and tear. This in turn shortens the time between overhauls, making the frequency drive less reliable overall, and requiring additional repair costs.

Competitors also do not state preventive diagnostics for the possibility of fan failure due to exhaustion, which also deprives the user of an important opportunity to plan ahead for maintenance service of the frequency drive.

Conclusion

Triol Corporation’s original solutions allow us to give new qualities to known things and differentiate them from the solutions of competitors. We don’t just solve problems by looking to use existing functionality, but by generating new solutions which make our equipment reliable, efficient, and easy to use!

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google