At the moment, in the complicated conditions of the artificial lift market, the general environmental problems of old wells, the increasingly harsh operating conditions of the installations, in the face of financial losses during hydrodynamic studies of high-yield wells, the requirements for submersible equipment, in particular, for downhole measuring system, have increased. Continuity, validity and accuracy of data play a key role in artificial lift technology. After analyzing the current market by Triol specialists, it was decided to create a new generation downhole measuring system TM01-20 and TM01-25, which have the following advantages over previous generations that will be significant for our customers:

- High-precision measurement of wells and submersible equipment, which will maximize the well flow rate;

- High accuracy of measured parameters;

- Economic efficiency;

- Reliability and durability;

- Easy to install and work with telemetry;

- Noise immunity and reliability of data;

- "Flexibility" and versatility;

- Resistance to aggressive environments;

- Tracking of mechanical failures;

- Possibility of carrying out hydrodynamic studies of wells. TM01-20 and TM01-25 are two new telemetry models that solve complex technological problems. Benefits for you and your client:

1.High accuracy of measured parameters

Without accurate and reliable data sources, your artificial lift system is vulnerable to significant operational risks that can prevent your resources from being produced at optimal rates. Temperature accuracy is ±1.8°F (±1°C) and pressure accuracy is ±5.8 psi (±0.04 MPa). When assembling TM01-25 with an ESP discharge unit, the ground equipment has a passive control system for the installation length, inclination and installation angle, which allows to determine the value of the discharge pressure with high accuracy. Due to the high telemetry measurements, low consumption is reduced and supplied from the well. TM01-20 and TM01-25 elevated ambient temperature up to 150°C while maintaining the declared sensitivity. Let's consider the well indicator diagram:

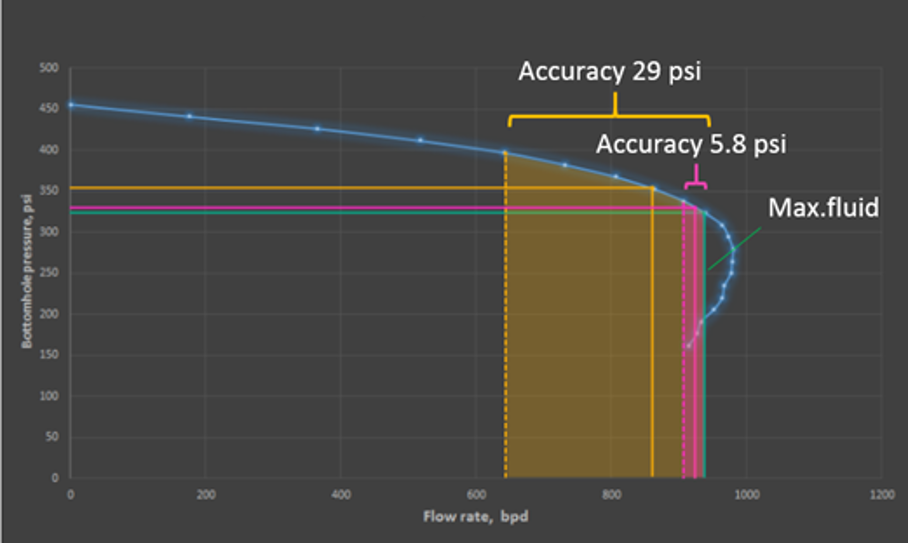

Flow rate vs. bottom hole pressure diagram

Flow rate vs. bottom hole pressure diagram

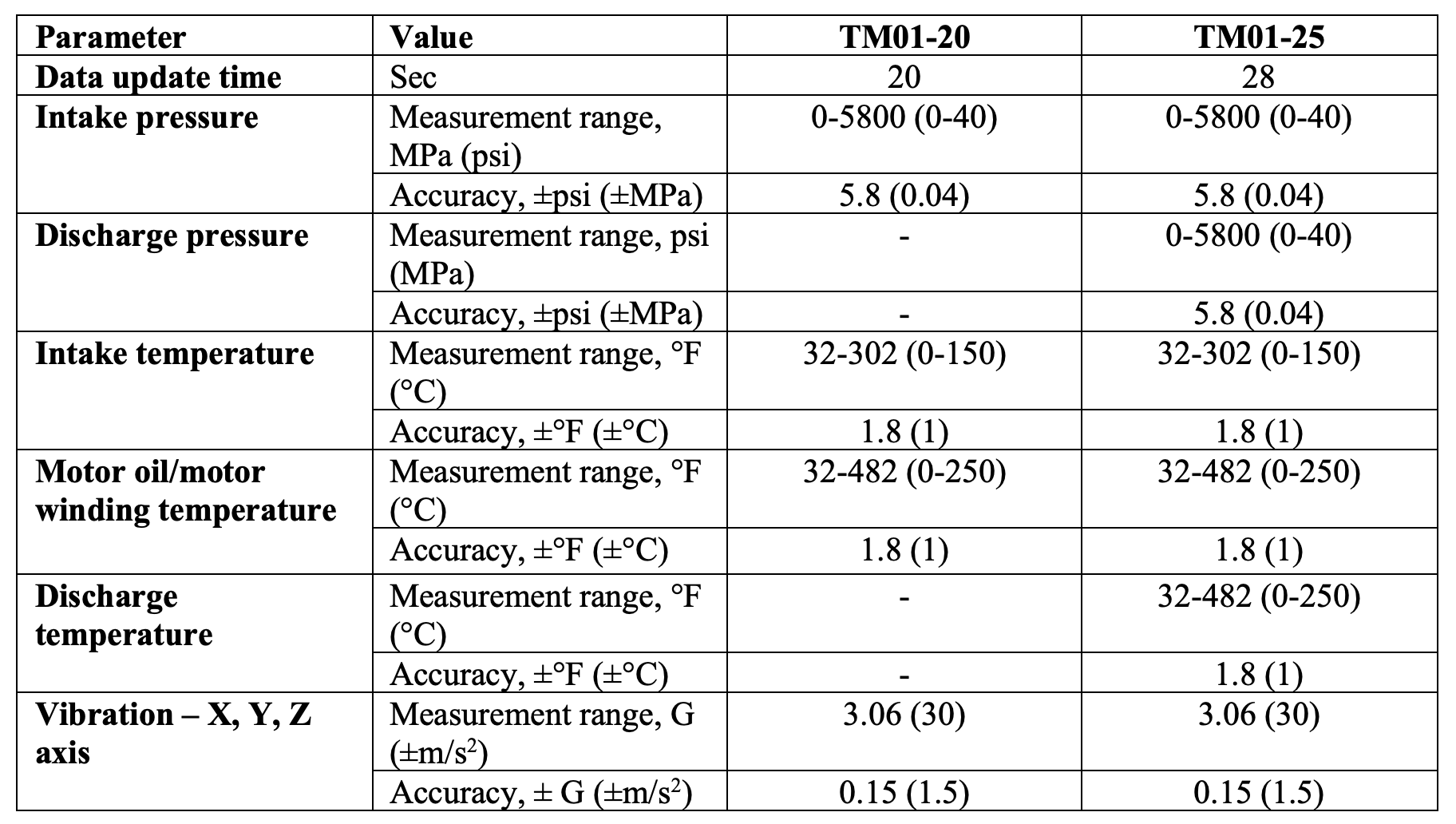

The graph shows that with a pressure measurement error of 29 psi, the unit is operating in the orange zone of observation, and the average rate is 861 bpd. Reducing the error in measuring pressure at an acceptable pump level to 5.8 psi. inch will allow the ESP to operate in a pink observer without critical pressure, which increases production by 7.3% (924 bpd) due to reservoir expansion, and also takes into account plant downtime. This technical solution is especially relevant for marginal wells, as well as unconventional wells, which pose unique challenges for operators. In highly active shale plays in many new markets, production usually drops sharply (80% in 2 years) and final production is quite low (less than 10%). This means that more than 90% of the hydrocarbons remain in the reservoir. TM01-20 and TM01-25 parameters:

The accuracy of the measured parameters of the downhole measuring system is confirmed by the test report included in the kit for each system. Calibration and verification is performed on a certified stand.

2. Economic efficiency through the use of ТМ01-25

Due to the unstable oil market, increasing the efficiency of production is more important than ever. The economic efficiency of using ТМ01-25 is possible due to the presence of a discharge temperature sensor. Due to the presence of this parameter, it is possible to increase the life of the pump by monitoring and further regulating the discharge temperature. The control of the parameter is carried out similarly to other parameters, the regulation consists in reducing the load on the pump bearings. By monitoring the discharge temperature, the start of pump bearing wear can be monitored, allowing users to:

- predict equipment replacement and reduce well downtime;

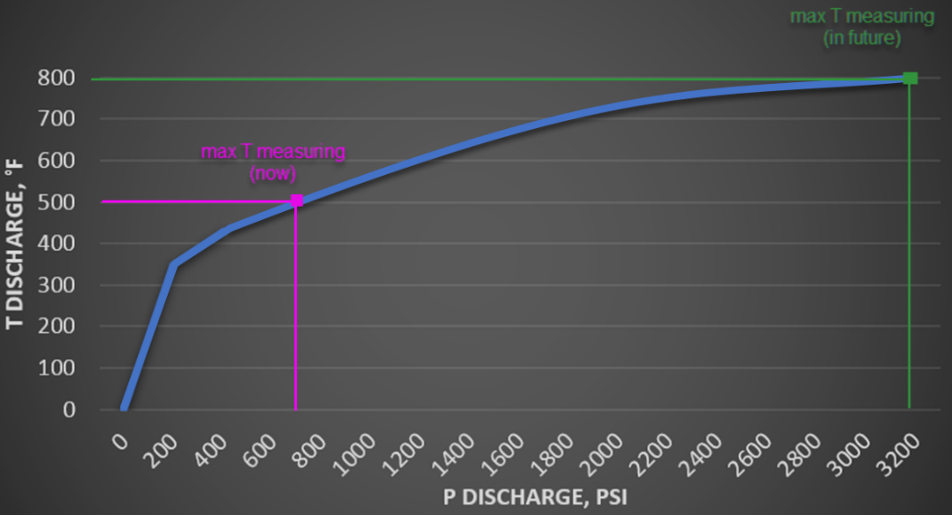

- adjust the operation of underwater equipment to increase the overhaul period. Increase in the overhaul period during the operation of centrifugal pumps in a fund complicated by salts. It is no secret that the process of scaling is maximum at the boiling of formation water. Consider the graph:

Data on temperature and pressure will help avoid formation water boiling and, as a result, increase the turnaround time and reduce tripping costs. Consider an example of calculations: The downtime of the well can be up to 2 days, with an average production of 314 barrels per day (50 m3/day) - this is 628 barrels (100 m3) of unproduced oil.

3.Reliability, which is guaranteed through the use of high-quality components from top manufacturers: ANALOG DEVICES, Texas Instruments, ATMEL, and AzSensCo.

Reliability as an economic category determines the degree of usefulness of the use value of products. Each telemetry undergoes acceptance testing, during which the product operates at maximum operating parameters for 10 days. All tests are aimed at admitting only high-quality and reliable products to the customer. Each line of the downhole measuring system undergoes life tests to determine the time between failures. The tests are conducted under maximum exposure to vibration, temperature and pressure parameters, and after life tests, the systems are checked to maintain the accuracy of the parameters, which can guarantee high-quality technical solutions for artificial lift.

Test flasks to simulate well conditions. The surface equipment of the stand to monitor operation.

Test flasks to simulate well conditions. The surface equipment of the stand to monitor operation.

4.Easy to install and work with telemetry.

Ease of working with telemetry is one of the key factors that Triol engineers are working on, since it is this factor that contributes to improving the quality of our partners' service. Installation time TM01 takes no more than 15 minutes. For the convenience of customers, we have developed a video instruction for installing and connecting telemetry.

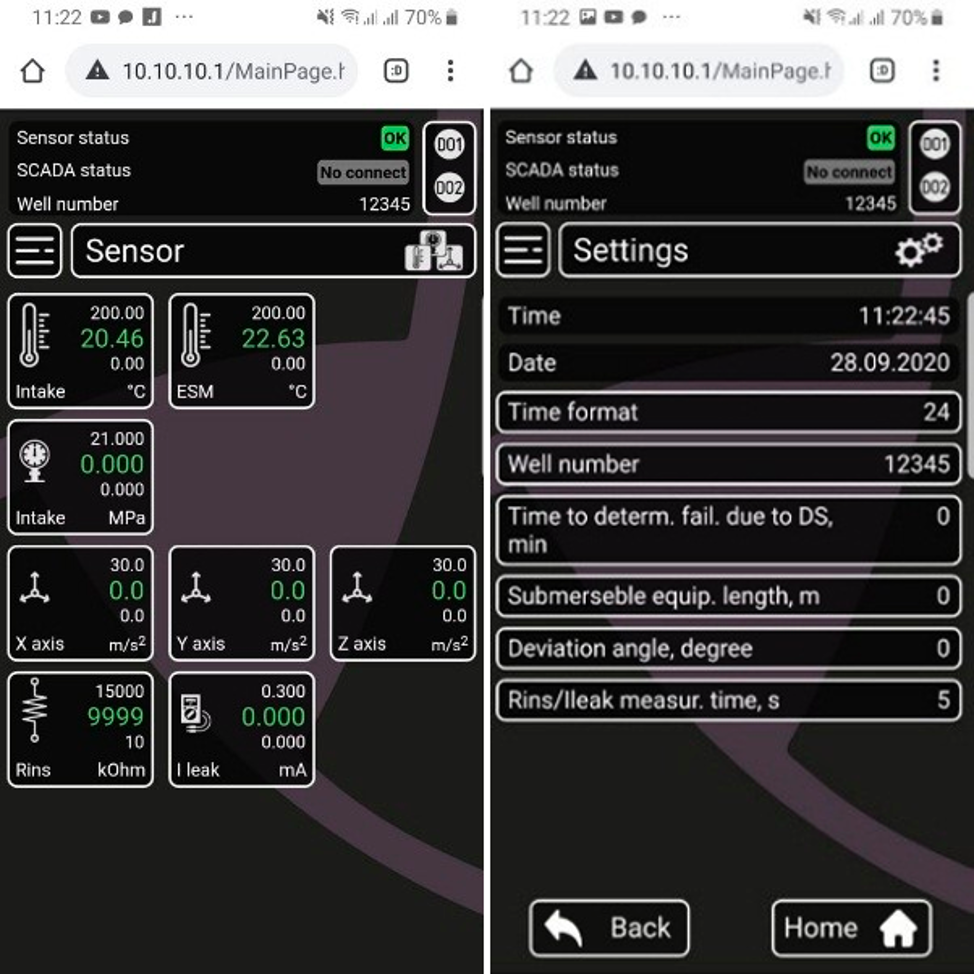

Conceptually new ground units of the downhole measuring system are designed for the convenience of users. Their main task is to improve the convenience of data processing and access to this data without the use of additional equipment. Triol ground equipment features: View the parameters of wells and submersible equipment on a mobile device without installing additional applications; Configuring the protection of connected equipment through discrete outputs on a mobile device.

View graphs of changes in telemetry parameters without special software or a laptop. Viewing graphs of all measured parameters is possible on the Triol Surface Card display. View graphs of changes in telemetry parameters without special software or a laptop. Viewing graphs of all measured parameters is possible on the Triol Surface Card display. In addition, the Triol Surface Card allows you to read the event log to a flash drive and view it on a PC using the software.

The Wi-Fi network of each surface part of TM01 is protected by password from outside connections.

As for connecting the Triol Surface Card to SCADA via the Modbus protocol, it is absolutely easy, since the Triol Surface Card has two communication surfaces RS-232 and RS-485. The device address map can be found in the Operation Manual Triol TM01 Surface Equipment and the SCADA connection is shown in detail in the video.

Let's consider two design versions Triol Surface Card: Triol Surface Card is rated IP20 and is used inside control stations or in other dust and waterproof environments. The main task is to receive data from the submersible unit and transmit it to the control system controller or SCADA.

Triol Surface Card

Triol Surface Card

The Triol Surface panel is NEMA 4X-rated and can be installed outside the control station, including on offshore platforms. If the customer's frequency drive has limited functionality or no display for control, you can use this device to set submersible equipment protections for parameters such as:

- ESP, discharge and intake temperature;

- discharge and intake pressure;

- vibrations;

- leakage current or resistant insulation. It is also possible to view data values and display graphs thanks to the helpful 5-inch display.

Triol Surface Panel

Triol Surface Panel

5.Noise immunity and data reliability

The electrical characteristics of the ESP are subject to temperatures at which interference may occur. In turn, interference affects the transmission of telemetry data. TM01 data transmission is implemented on the basis of the Manchester-II transmission protocol, which is carried out at a frequency of 6-13 Hz, which ensures the integrity of the data of the downhole measuring system when using an ESP with an operating frequency of 35 Hz. The downhole measurement system is equipped with a high voltage second order LC low pass filter with a cutoff frequency of 22 Hz.

This filter allows you to test telemetry for insulation resistance at a voltage of 5 kV for 1 min. It also provides noise filtering at the zero point of the installation, which allows you to correctly obtain data with noise of 600 V 50 Hz and 1000 V 100 Hz (voltage is indicated by the amplitude value).

After each data packet is received, a CRC check is performed so that only valid parameter values can be displayed. When using Triol High-Voltage Choke not only in a system with a delta-connected transformer, but also in a star-connected one, you will get additional noise immunity and data protection.

ТМ01-20 and ТМ01-25 have a self-diagnosis system for the state of sensors. Before measuring all parameters, testing for a short circuit and an open circuit of all sensors is carried out. It is excluded that the microcontroller receives incorrect parameter values, which could have been in the absence of this function, since interference may be introduced into the measurement channel and incorrect data output.

6. "Flexibility" and versatility

Due to the fact that there is a large number of equipment for oil production on the market, which has a range of types of connecting sizes, sensors, etc., there is a need to increase the versatility of the downhole measuring system TM01.

Versatility is achieved by universal connection to any type of engine and operation with RDT and J type temperature sensors. ТМ01-20 and ТМ01-25 provide connection of RDT or J type temperature sensors. The temperature sensor is supplied with telemetry, but the customer can use his own sensors temperature.

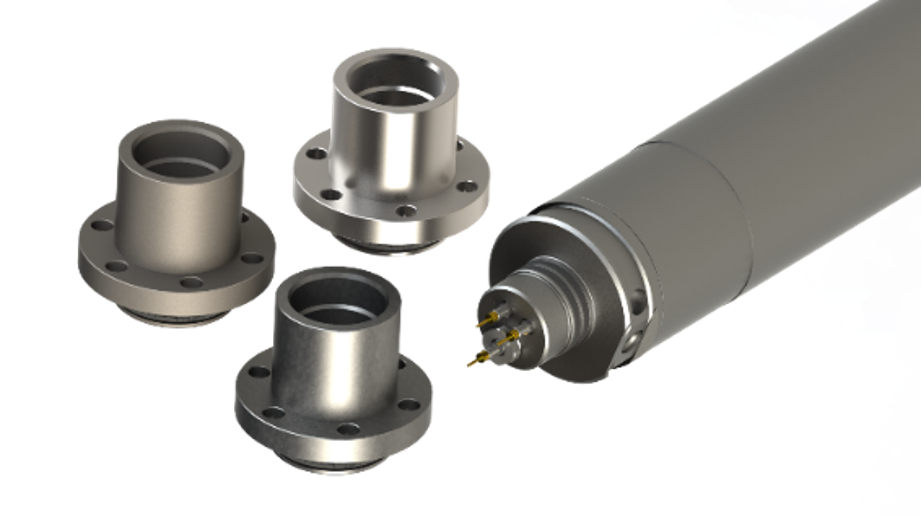

The external diameter of the telemetry is 3.75 inches (96 mm). And the flange mounting system allows to connect the TM01 without using additional adapters and as a consequence without increasing the sealing locations as one of the risks of failure of the submersible motor. All flanges can be found in the "Flange adapter catalog". If there is no suitable flange in the catalog, you can send us drawings of the required flange for individual production.

When using the Triol Surface Board, it is possible to connect it to a power supply with a voltage of 100-250 VAC and a frequency of 50/60 Hz. Triol Surface Card can be made without dust and moisture protection, complete with universal mounts for mounting on a 35 mm DIN rail, as well as in a NEMA4X case with the ability to connect to a voltage source of 100-240 VAC, as well as 24 VDC, and the ability to installations in a hostile environment.

Triol High-Voltage Choke also has 2 versions:

- in NEMA4X case;

- with degree of protection IP00, having compact overall dimensions.

Download the catalog "Downhole Measuring Systems Triol TM01" and learn more about this product!

We are confident that through this cooperation, you will solve all your most complex problems in the most profitable way for you!

7. Resistance to aggressive environments

Taking into account the conditions of the complicated production environment, the presence of salt deposits, the presence of hydrogen sulfide, our engineers developed a technical solution using AISI 304 (12x18n10t) and AISI 420 (40x13) stainless steel in the new lines. This technical solution makes it possible to reduce the impact of aggressive environments on telemetry details, which makes it possible to operate telemetry for a long period, as well as during repeated descent. At the same time, there is no change in the strength characteristics of the product.

8. Tracking of mechanical failures

ESP as a mechanical system refers to rotary motor, the operation of which is accompanied by vibration due to many reasons. The main distinguishing feature of submersible centrifugal pumps is the ratio of length to diameter, which is uncharacteristic for conventional rotary machines - it is hundreds of times higher. In the new TM01 ranges, a technical solution was introduced with the measurement of the peak value of vibration in the range of 0 - 5 G and the measurement error of 5% FS, which allows covering the possible range of mechanical vibration ESP and based on this to draw conclusions about the state of the installation by analyzing the dynamics of changes in the vibration value, and also calculate the critical wear point ESP. As everyone knows, in the calculations it is necessary to use the RMS vibration value. TM01-20 and TM01-25 can be supplied on request with the ability to measure vibration acceleration RMS in the range of 0 - 3 G. Depending on the specifics of your submersible equipment, you can choose the required configuration.

9. The possibility of conducting hydrodynamic studies of wells

Downtime of wells for hydrodynamic studies significantly affects the amount of oil produced. The use of downhole measuring system TM01-20 or TM01-25, depending on the requirements, in combination with the Triol Surface Card, will allow you to avoid well downtime for such surveys. Most of the used telemetry systems have insufficient resolution and accuracy for conducting hydrodynamic studies of the well, while ТМ01-20 and ТМ01-25 have a resolution of 0.1 psi (0.001 MPa) and high accuracy. In turn, the Triol Surface Card has the ability to record data in the event log for conducting a technological analysis of the well and making further decisions on its operation mode.

Thus, the new lines of downhole measuring system Triol TM01-20 and TM01-25 have a number of advantages for our partners, which will improve the efficiency of artificial lift.

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google