1. CONVERTERS FOR INDOOR INSTALLATION.

The simplest versions of medium voltage frequency and variable frequency drives on the market are cabinet-type VFDs with a low enclosure (no more than IP42 / NEMA2), and a forced air cooling system, for installation in electrical rooms. Variable frequency drives in this design are manufactured by more than 30 companies worldwide.

Triol also offers its own cabinet solution. This is an AT27 line ED ("energy drive") with IP31 (NEMA 2) or IP42 enclosure, operating temperature from -10°C to +50°C.

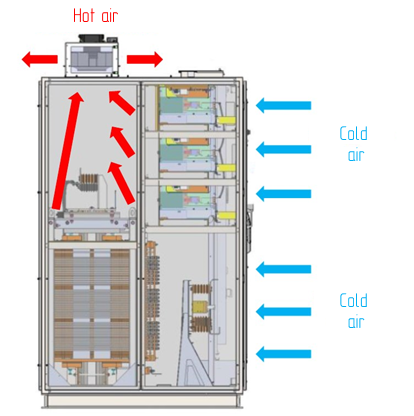

AT27 ED cooling type - forced air. The cooling system is based on roof-mounted exhaust fans. There are no fans inside the VFD cabinets.

Air intake is from the front of the inverter, hot air is discharged from the top. To increase the life of Triol AT27 VFDs, the fan speed is optimized depending on the temperature of the windings of the power transformer and the temperature of the IGBT of the power cells.

The entire ventilation system is built according to the scheme of intelligent redundancy of fans, which allows distribution of the load between the fans to provide sufficient cooling conditions for the inverter at any time. Thanks to the smart redundancy scheme, it is possible to replace a failed fan safely and quickly without stopping the inverter and without reducing its power.

We will look at this option in more detail in one of the following articles in this section.

2. What increases the required investment in the application of medium voltage drives in premises and what Triol offers to reduce such investments.

So, many companies offer cabinet-type medium voltage drives. At the same time, the required operating conditions for these inverters are close to laboratory ones – without moisture, dust, condensation, corrosive gases, and with the operating temperature from 0 to 40°C. But it is far from possible to always provide "comfortable" working conditions for cabinet-type variable frequency drives at facilities.

In most cases, additional investments are required in the preparation of premises in terms of:

- Installation of air purification and preparation systems

- Installation of ventilation, air conditioning and heating systems

- Carrying out capital construction / renovation of premises or the installation of modular cabinets.

All this leads to additional investments, and an increase in the implementation time and payback of the project.

In this case, the decisions must be calculated accurately, since if the ventilation system is incorrectly selected, the VFD stops due to overheating. Operation at elevated temperatures always leads to a reduction in equipment life. In this case, it is necessary to purchase and install additional cooling systems or apply methods such as opening doors in a room to provide additional air inflow or outflow, or forced reduction of equipment power. In the first case, dust is drawn into the room, in the second, technological losses cannot be avoided and, as a result, profit decreases.

If an air preparation system is used in the room, then the risks from the penetration of dust and small insects into the room still remain, because the doors to the room are periodically opened. An excess amount of dust, small insects, over time leads to:

- Rapid wear of air filters, i.e. additional costs for consumables and maintenance. If the air filters are not replaced in a timely manner, the thermal protection will operate, and the inverter will shut down.

- Electrical breakdown due to finely dispersed dust settled inside the variable frequency drive. Electrical flashover can result in substantial damage to the equipment, even leading to a fire.

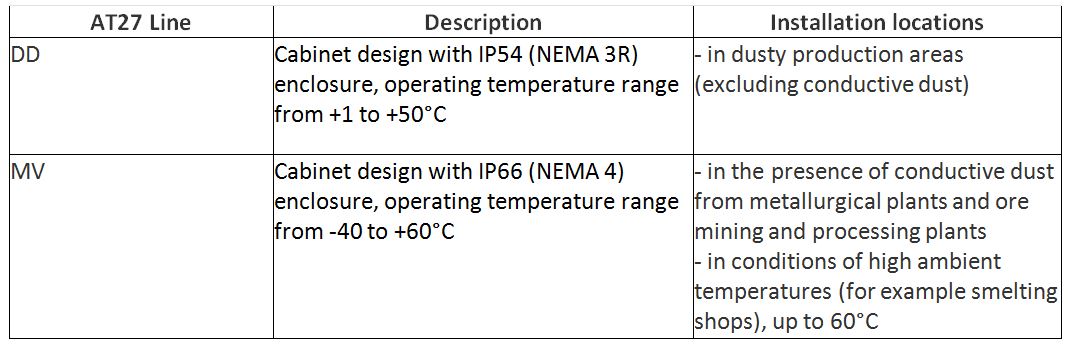

To reduce the size of investments, to reduce risks in the design and preparation of premises, as well as to simplify the subsequent long-term operation of such equipment, Triol offers two remarkable solutions within the Triol AT27 series:

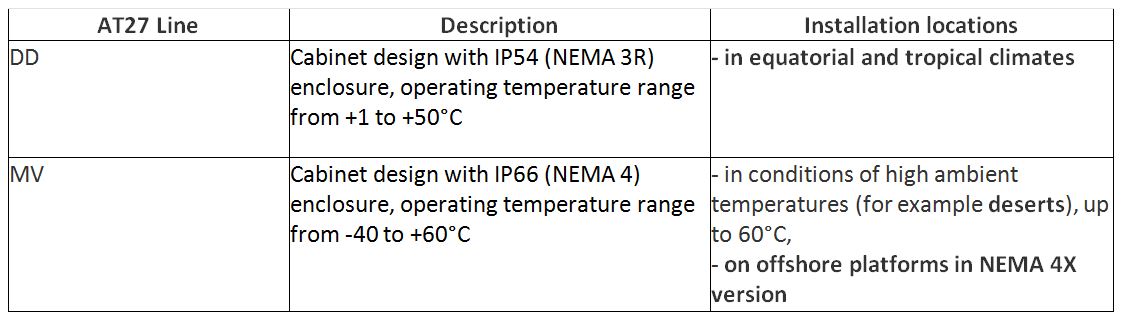

DD and MV lines have the same design solutions but differ in the organization of the cooling system. Initially, these lines were designed for use in equatorial, tropical climates and deserts. However, they have found their application in industrial conditions indoors!

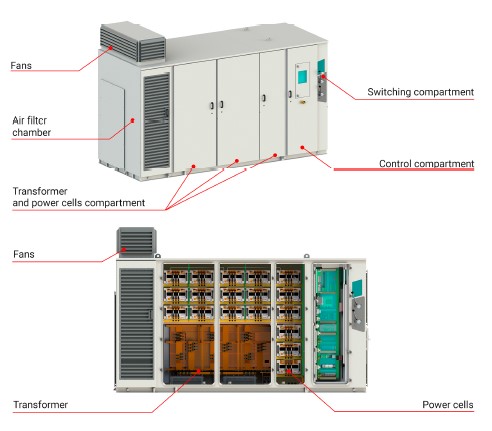

Triol AT27 DD and MV VFDs consist of:

- Power cells and transformer cabinet

- Air preparation (for DD line) or heat exchangers (for MV line) cabinets.

- Switching cabinet

- Control cabinet

- Fans

The switching cabinet includes an upstream disconnector, an upstream earthing switch, surge arresters and connection terminals. In addition, this cabinet can be equipped with a vacuum contactor for the input and a power supply transformer for the auxiliary needs of the frequency drive. The connection cabinet has a special door for easy maintenance.

The transformer has a withdrawable design, which allows it to be removed from the VFD housing in case repair work is needed.

The cooling system of Triol AT27 DD is based on centrifugal exhaust fans installed on the roof. Triol AT27 MV has a two-circuit cooling system based on air-to-air heat exchangers. This system allows you to reliably separate the environment from the internal space of the inverter.

The innovative design of the transformer and the optimized cooling system of the power cells with parallel cooling of the semiconductor modules ensure the operation of the AT27 MV in conditions of the highest ambient temperatures with the declared rated parameters.

To prevent dust and debris from getting inside the cabinets, the AT27 ED inverter is equipped with an air filter system. The replacement of filters can be carried out without stopping the operation of the inverter and is safe for service personnel.

Summary: before moving on to conclusions, remember that despite the disadvantages described earlier, the cabinet version of the inverter has its advantages:

+Relatively low price

+Small overall dimensions

+Various options for installation (cabinets in one line, "back to back", spaced across the shop) and service (one- and two-sided)

+Large assortment

+Minimum delivery time and a high probability of receiving the product from the warehouse.

Thus, the three Triol AT27 lines ED, DD, and MV, while maintaining the advantages of the cabinet design of the medium voltage frequency drive, allow additional investments and costs during operation to be avoided, which provides our customers and partners with benefits both in design and operation, and in the implementation of investment projects for the construction or modernization of the main production.

3. Variable frequency drives for outdoor installation.

First, let's go back to the DD and MV lines. For outdoor usage, the previously discussed table takes on a different look:

АТ27 DD and MV - unique design solutions for 3-11kV inverters for operation both indoors and outdoors! To the best of our knowledge, no one else in the world has medium voltage drives with NEMA 4 and NEMA 4X enclosures.

We’ve considered the most obvious solutions; let's move on to other solutions.

For outdoor usage, some companies offer the option of supplying cabinet-type frequency drives as part of block-modular buildings with a factory warranty for the entire supply. With this version of the frequency manager, many organizational headaches are removed from the customer and the designer:

- Building

- VFD

- Ventilation, air conditioning, heating system

- Fire alarm

- Factory warranty

For the maintenance personnel, this solution has some disadvantages:

- Narrow aisles, especially with open cabinet doors, make maintenance difficult.

- The temperature inside the buildings, with the VFD operating, can exceed 40°C even in winter, which creates uncomfortable conditions for the service personnel.

- The air filter and / or air conditioning system require periodic maintenance.

Such product lines as TMDrive-Guardian (“TMEIC”, Japan / USA) and XMV660 Outdoor (“Power Electronics”, Spain) provide service only from the street, which brings even more inconvenience: the inability to service in bad weather entails equipment downtime and losses.

There is one more aspect that is important to mention. In the case of using block-modular buildings (BMB), controversial situations may arise in the correct selection of equipment and operating conditions. For example, if the inverter is inoperable once installed in a new BMB, is it the manufacturer of the inverter or the supplier of the BMB that is responsible for the inoperability, or did the design organization not take into account all the operating modes, operating conditions, and requirements of the inverter cooling system? These organizational issues can "bleed and drink " and require special attention and additional time at both the stage of formulating the requirements for project implementation and at the design stage.

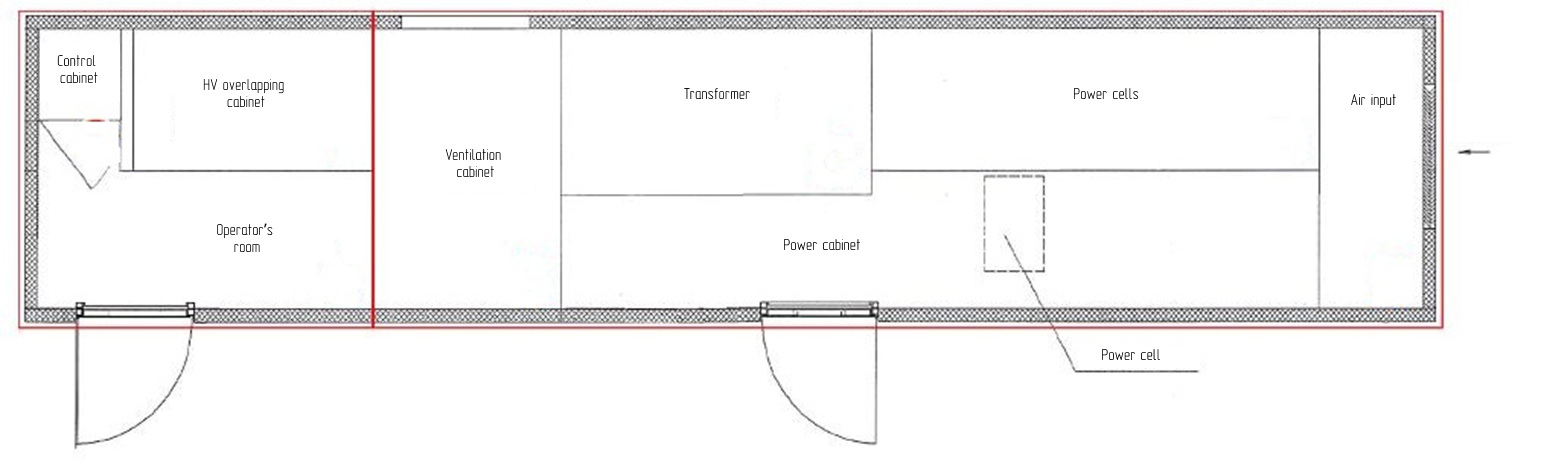

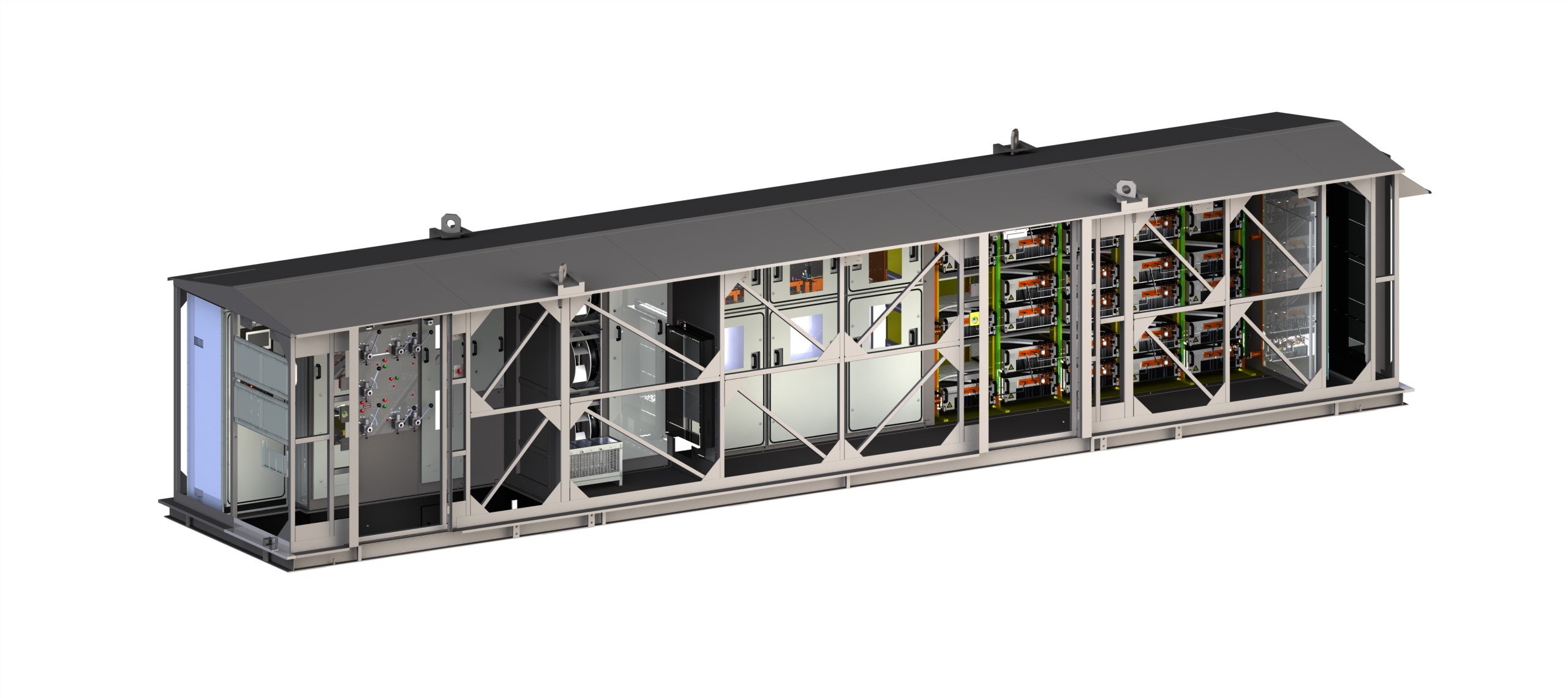

How did we approach this question at Triol? Within the Triol AT27 series of converters, we offer an alternative container (block-box) solution - the RX line (Robust XForm).

AT27 RX is successfully operated outdoors at ambient temperatures from -60 to +50°C. In this case enclosure is IP43 rated. Two cabinets are structurally distinguished - the operator's cabinet and the high-voltage cabinet. The operator's cabinet is constantly maintained at a comfortable temperature due to the heating and air conditioning system. All AT27 RX controls are in the operator's cabinet. In cold or hot conditions, you can always enter the operator's cabinet and work at a comfortable temperature.

The power cabinet is provided with passages of at least 1m for comfortable equipment maintenance. To access the power cells, you do not need to open the doors – they are all in sight and are ready for quick replacement if necessary.

RX line block-boxes are by necessity equipped with a microclimate control system, which consists of exhaust fans, external and internal dampers with electric drive control, heaters, and sensors for measuring temperature, humidity, and differential pressure.

Well-thought-out algorithms for cooling and heating, dew point calculation, and block-box drying guarantee normal operation of the power cells and transformer, and, for the consumer, a long period of trouble-free operation.

Container solutions also have their drawbacks:

- Reduction in the efficiency of the whole converter by 2-3% due to the air conditioning and heating system

- Protection from dust is also not fully ensured, since BMB have an enclosure no more than IP55 (NEMA 3R), and there remains a risk of electrical breakdown when the container is installed in places with high dust content.

Thus, when solving the investment and technological problem, the designer, customer, and contractor must carefully consider all possible alternatives and make the right decision. The good news is that Triol offers a unique and diverse set of solutions to these problems, which makes each project as profitable and reliable as possible.

To summarize: AT27 VFDs have 4 different lines for different operating conditions.

You can download theTriol AT27 medium voltage frequency drive catalogto learn about this equipment in more detail.

If you have any questions, ask our specialists. Call or email us, we will be happy to answer!

Oleg Kozak Tel.: +38-067-627-10-85, kozak@triolcorp.com;

Is the Triol AT27 frequency drive ready to work in most climatic conditions and industrial environments? Yes! The main thing is to choose the right one.

subscribe.el.title

- Product news

- Events

- Discounts

1(405)6157755 (Business)

1(405)6157755 (Business)

Google

Google